| [1] |

范慧敏. 预制菜市场分析[J]. 合作经济与科技,2023,699(4):88−89. [FAN H M. Market analysis of prefabricated dishes[J]. Co-Operative Economy & Science,2023,699(4):88−89.]

FAN H M. Market analysis of prefabricated dishes[J]. Co-Operative Economy & Science, 2023, 699(4): 88−89.

|

| [2] |

赵超凡, 陈树俊, 李文兵, 等. 预制菜产业发展问题分析[J]. 现代食品科技,2023(2):104−109. [ZHAO C F, CHEN S J, LI W B, et al. Analysis on the development problems of prepared dish industry[J]. Modern Food Science and Technology,2023(2):104−109.]

ZHAO C F, CHEN S J, LI W B, et al. Analysis on the development problems of prepared dish industry[J]. Modern Food Science and Technology, 2023(2): 104−109.

|

| [3] |

王炜, 杨丹. 新冠肺炎疫情下餐饮业的新发展——预制菜肴的加工应用[J]. 食品工业,2022,43(12):169−171. [WANG W, YANG D. New developments in the catering industry in the face of COVID-19—The processing and application of prefabricated dishes[J]. The Food Industry,2022,43(12):169−171.]

WANG W, YANG D. New developments in the catering industry in the face of COVID-19—The processing and application of prefabricated dishes[J]. The Food Industry, 2022, 43(12): 169−171.

|

| [4] |

邓衍军, 陈宇, 杨国栋. 广东省预制菜产业发展现状分析[J]. 现代农业装备,2022,43(6):16−19,65. [DENG Y J, CHEN Y, YANG G D. Analysis on current situation of prefabricated vegetable industry in Guangdong Province[J]. Modern Agricultural Equipment,2022,43(6):16−19,65.]

DENG Y J, CHEN Y, YANG G D. Analysis on current situation of prefabricated vegetable industry in Guangdong Province[J]. Modern Agricultural Equipment, 2022, 43(6): 16−19,65.

|

| [5] |

ZHANG Y R, WANG D W, CHEN Y T, et al. Healthy function and high valued utilization of edible fungi[J]. Food Science and Human Wellness,2021,10(4):408−420. doi: 10.1016/j.fshw.2021.04.003

|

| [6] |

QIN P F, LI T Y, LIU C, et al. Extraction and utilization of active substances from edible fungi substrate and residue:A review[J]. Food Chemistry,2023,398:133872. doi: 10.1016/j.foodchem.2022.133872

|

| [7] |

SUN Y L, ZHANG M, FANG Z X. Efficient physical extraction of active constituents from edible fungi and their potential bioactivities:A review[J]. Trends in Food Science & Technology,2020,105:468−482.

|

| [8] |

张韵, 李蕙蕙, 周圣弘. 食用菌作为预制即热菜肴的应用前景及途径[J]. 食品安全导刊,2021(34):138−140. [ZHANG Y, LI H H, ZHOU S H. Application prospect and realization of edible fungi as ready-to-heat Cuisine[J]. China Food Safety Magazine,2021(34):138−140.]

ZHANG Y, LI H H, ZHOU S H. Application prospect and realization of edible fungi as ready-to-heat Cuisine[J]. China Food Safety Magazine, 2021(34): 138−140.

|

| [9] |

范秀芝, 姚芬, 殷朝敏, 等. 香菇预制菜制备工艺优化[J]. 食品工业科技,2023,44(12):223−231. [FAN X Z, YAO F, YIN C M, et al. Optimization of the preparation process of Lentinula edodes prefabricated dishes[J]. Science and Technology of Food Industry,2023,44(12):223−231.]

FAN X Z, YAO F, YIN C M, et al. Optimization of the preparation process of Lentinula edodes prefabricated dishes[J]. Science and Technology of Food Industry, 2023, 44(12): 223−231.

|

| [10] |

曹晶晶, 孙达锋, 苟学磊, 等. 食用菌预制菜加工现状分析及展望[J]. 中国食用菌,2022,41(10):62−65. [CAO J J, SUN D F, GOU X L, et al. Analysis and prospect of current processing situation of the prefabricated edible fungi dishes[J]. Edible Fungi of China,2022,41(10):62−65.]

CAO J J, SUN D F, GOU X L, et al. Analysis and prospect of current processing situation of the prefabricated edible fungi dishes[J]. Edible Fungi of China, 2022, 41(10): 62−65.

|

| [11] |

桑兰, 杨珍福, 王婷婷, 等. 我国食用菌汤类产品研究进展[J]. 科技创新导报,2015,12(7):10−13. [SANG L, YANG Z F, WANG T T, et al. The development of study on the soup products of edible fungi in China[J]. Science and Technology Innovation Herald,2015,12(7):10−13.] doi: 10.3969/j.issn.1674-098X.2015.07.006

SANG L, YANG Z F, WANG T T, et al. The development of study on the soup products of edible fungi in China[J]. Science and Technology Innovation Herald, 2015, 12(7): 10−13. doi: 10.3969/j.issn.1674-098X.2015.07.006

|

| [12] |

付瑞青, 王娟, 郭衍银, 等. 基于GC-MS和氨基酸分析的羊肚菌汤适宜煮制时间研究[J]. 食品工业科技,2022,43(16):290−297. [FU R Q, WANG J, GUO Y Y, et al. Suitable cooking time of Morchella soup based on GC-MS and amino acid analysis[J]. Science and Technology of Food Industry,2022,43(16):290−297.]

FU R Q, WANG J, GUO Y Y, et al. Suitable cooking time of Morchella soup based on GC-MS and amino acid analysis[J]. Science and Technology of Food Industry, 2022, 43(16): 290−297.

|

| [13] |

LEYGONIE C, BRITZ T J, HOFFMAN L C. Impact of freezing and thawing on the quality of meat:Review[J]. Meat Science,2012,91(2):93−98. doi: 10.1016/j.meatsci.2012.01.013

|

| [14] |

HOLZWART M, KORHUMMEL S, CARLE R, et al. Evaluation of the effects of different freezing and thawing methods on color, polyphenol and ascorbic acid retention in strawberries ( Fragaria× ananassa Duch.)[J]. Food Research International,2012,48(1):241−248. doi: 10.1016/j.foodres.2012.04.004

|

| [15] |

卢琪, 薛淑静, 杨德, 等. 不同干燥条件下福白菊菊花茶风味品质的比较分析[J]. 食品科学,2020,41(20):249−255 [LU Q, XUE S J, YANG D, et al. Comparative analysis of flavor quality of Chrysanthemum tea (Chrysanthemum morifolium cv. ‘Fubaiju’) processed by different drying methods[J]. Food Science,2020,41(20):249−255.]

LU Q, XUE S J, YANG D, et al. Comparative analysis of flavor quality of Chrysanthemum tea (Chrysanthemum morifolium cv. ‘Fubaiju’) processed by different drying methods[J]. Food Science, 2020, 41(20): 249−255.

|

| [16] |

徐亚, 范会芬, 赵玎玲, 等. 考马斯亮蓝法测定大豆水溶性蛋白提取方法的优化[J]. 大豆科学,2022,41(2):196−202. [XU Y, FAN H F, ZHAO D L, et al. Optimization of extraction method for water-soluble protein determination by coomassie bright blue method[J]. Soybean Science,2022,41(2):196−202.]

XU Y, FAN H F, ZHAO D L, et al. Optimization of extraction method for water-soluble protein determination by coomassie bright blue method[J]. Soybean Science, 2022, 41(2): 196−202.

|

| [17] |

WANG Q, REHMEN M, PENG D X, et al. Antioxidant capacity and α-glucosidase inhibitory activity of leaf extracts from ten ramie cultivars[J]. Industrial Crops and Products,2018,122:430−437. doi: 10.1016/j.indcrop.2018.06.020

|

| [18] |

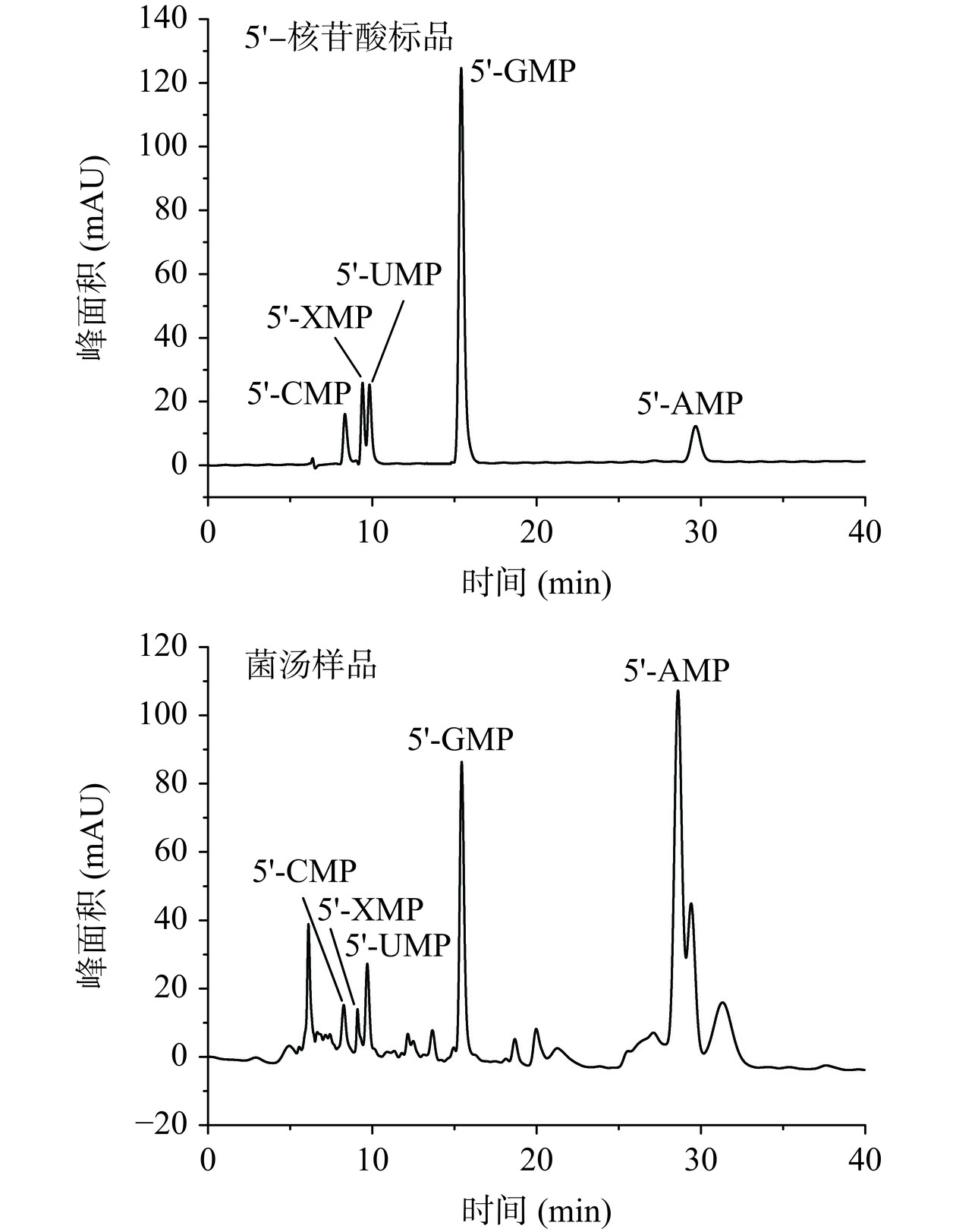

LU Q, WANG S H, XUE S J, et al. Comparison of non-volatile flavor compounds in Stropharia rugosoannulata soup processed by different methods[J]. Journal of Food Science and Technology,2022,59(10):4025−4036. doi: 10.1007/s13197-022-05446-9

|

| [19] |

VAKILI H, TALEBPOUR Z, HAGHIGHI F. Development, validation, and uncertainty measurement of HPLC-DAD method for determination of some free amino acids in infant formula and medical food products for inborn errors of metabolism[J]. Food Chemistry,2022,390:133204.

|

| [20] |

卢琪, 薛淑静, 杨德, 等. 不同加工方式对羊肚菌水提液鲜味及抗氧化性能的影响[J]. 食品工业科技,2022,43(15):27−33. [LU Q, XUE S J, YANG D, et al. Effects of different processing methods on umami taste and antioxidant capability of water extracts of Morchella esculenta[J]. Journal of Food Science and Technology,2022,43(15):27−33.]

LU Q, XUE S J, YANG D, et al. Effects of different processing methods on umami taste and antioxidant capability of water extracts of Morchella esculenta[J]. Journal of Food Science and Technology, 2022, 43(15): 27−33.

|

| [21] |

REN J N, TAI Y N, DONG M, et al. Characterisation of free and bound volatile compounds from six different varieties of citrus fruits[J]. Food Chemistry,2015,185:25−32. doi: 10.1016/j.foodchem.2015.03.142

|

| [22] |

卢琪, 薛淑静, 杨德, 等. 不同加工方式对大球盖菇水提液挥发性风味成分和抗氧化能力的影响[J]. 食品工业科技,2021,42(23):41−48 [LU Q, XUE S J, YANG D, et al. Effects of different processing methods on the volatile components and antioxidant ability of the water extracts from Stropharia rugosoannulata[J]. Science and Technology of Food Industry,2021,42(23):41−48.]

LU Q, XUE S J, YANG D, et al. Effects of different processing methods on the volatile components and antioxidant ability of the water extracts from Stropharia rugosoannulata[J]. Science and Technology of Food Industry, 2021, 42(23): 41−48.

|

| [23] |

张莉会, 刘杜娟, 廖李, 等. 真空冷冻-热风联合干燥对草莓品质的影响[J]. 现代食品科学,2018,34(4):188−197. [ZHANG L H, LIU D J, LIAO L, et al. Effects of vacuum freezing combined with hot air drying on the quality of strawberry[J]. Modern Food Science and Technology,2018,34(4):188−197.]

ZHANG L H, LIU D J, LIAO L, et al. Effects of vacuum freezing combined with hot air drying on the quality of strawberry[J]. Modern Food Science and Technology, 2018, 34(4): 188−197.

|

| [24] |

韦舟平. 冷冻工艺对中式预制菜肴品质的影响及提升策略研究[J]. 现代食品,2022,41(1):51−56 [WEI Z P. Study on the freezing technology and quality control strategy of chinese prepared dishes[J]. Modern Food,2022,41(1):51−56.]

WEI Z P. Study on the freezing technology and quality control strategy of chinese prepared dishes[J]. Modern Food, 2022, 41(1): 51−56.

|

| [25] |

LI Q, ZHANG H, CLAVER I P, et al. Effect of different cooking methods on the flavour constituents of mushroom (Agaricus bisporus (Lange) Sing.) soup[J]. International Journal of Food Science & Technology,2011,46(5):1100−1108.

|

| [26] |

郑小玲, 唐柏彬, 李贤良, 等. 基于超高效液相色谱-高分辨质谱法的冷冻过程中猪肉差异物质代谢组学分析[J]. 食品安全质量检测学报,2022,13(12):3825−3833. [ZHENG X L, TANG B S, LI X L, et al. Metabolomics analysis of differential substances in pork during freezing based on ultra performance liquid chromatography-high resolution mass spectrometry[J]. Journal of Food Safety & Quality,2022,13(12):3825−3833.] doi: 10.3969/j.issn.2095-0381.2022.12.spaqzljcjs202212012

ZHENG X L, TANG B S, LI X L, et al. Metabolomics analysis of differential substances in pork during freezing based on ultra performance liquid chromatography-high resolution mass spectrometry[J]. Journal of Food Safety & Quality, 2022, 13(12): 3825−3833. doi: 10.3969/j.issn.2095-0381.2022.12.spaqzljcjs202212012

|

| [27] |

LI W, GU Z, YANG Y, et al. Non-volatile taste components of several cultivated mushrooms[J]. Food Chemistry,2014,143:427−431. doi: 10.1016/j.foodchem.2013.08.006

|

| [28] |

YIN C M, FAN X Z, FAN Z, et al. Comparison of non-volatile and volatile flavor compounds in six Pleurotus mushrooms[J]. Journal of the Science of Food and Agriculture,2019,99(4):1691−1699. doi: 10.1002/jsfa.9358

|

| [29] |

谢丽源, 兰秀华, 唐杰等. 不同羊肚菌品种氨基酸营养评价及等鲜浓度值差异分析[J]. 天然产物研究与开发,2020,32(6):1023−1029, 979. [XIE L Y, LAN X H, TANG J, et al. Nutritional evaluation of different amino acids and difference analysis of equivalent umami concentration in Morchella spp

J]. Natural Product Research and Development,2020,32(6):1023−1029, 979.

|

| [30] |

HUA R, JIANG J X. Small leucine-rich proteoglycans in physiological and biomechanical function of bone[J]. Matrix Biology Plus,2021,11:100063. doi: 10.1016/j.mbplus.2021.100063

|

| [31] |

YOSHIMURA Y, BISE T, SHIMAZU S R, et al. Effects of a leucine-enriched amino acid supplement on muscle mass, muscle strength, and physical function in post-stroke patients with sarcopenia:A randomized controlled trial[J]. Nutrition,2019,58:1−6. doi: 10.1016/j.nut.2018.05.028

|

| [32] |

GUO Q Y, ADELINA N M, HU J T, et al. Comparative analysis of volatile profiles in four pine-mushrooms using HS-SPME/GC-MS and E-nose[J]. Food Control,2022,134:108711. doi: 10.1016/j.foodcont.2021.108711

|

| [33] |

毕永昭, 单启梅, 罗瑞明等. 不同冻结速率手抓羊肉挥发性风味物质差异分析[J]. 食品科学,2023,44(2):288−295. [BI Y Z, SHAN Q M, LUO R M, et al. Differences in volatile flavor compounds in hand-grab mutton frozen at different freezing rates[J]. Food Science,2023,44(2):288−295.]

BI Y Z, SHAN Q M, LUO R M, et al. Differences in volatile flavor compounds in hand-grab mutton frozen at different freezing rates[J]. Food Science, 2023, 44(2): 288−295.

|

| [34] |

宋春燕, 王琪, 单壹壹, 等. 2, 4-二叔丁基苯酚对细叶小羽藓生理的影响[J]. 上海师范大学学报(自然科学版),2022,51(6):742−749. [SONG C Y, WANG Q, SHAN Y Y, et al. Effects of 2,4-di-tert-butyl phenol on physiology of Haplocladium microphyllum[J]. [J]. Journal of Shanghai Normal University(Natural Sciences),2022,51(6):742−749.]

SONG C Y, WANG Q, SHAN Y Y, et al. Effects of 2,4-di-tert-butyl phenol on physiology of Haplocladium microphyllum[J]. [J]. Journal of Shanghai Normal University(Natural Sciences), 2022, 51(6): 742−749.

|

DownLoad:

DownLoad: