Effect of Bubble Green Vegetable Powder on Flour and Dough Properties and Its Optimization of Dried Noodles Processing

-

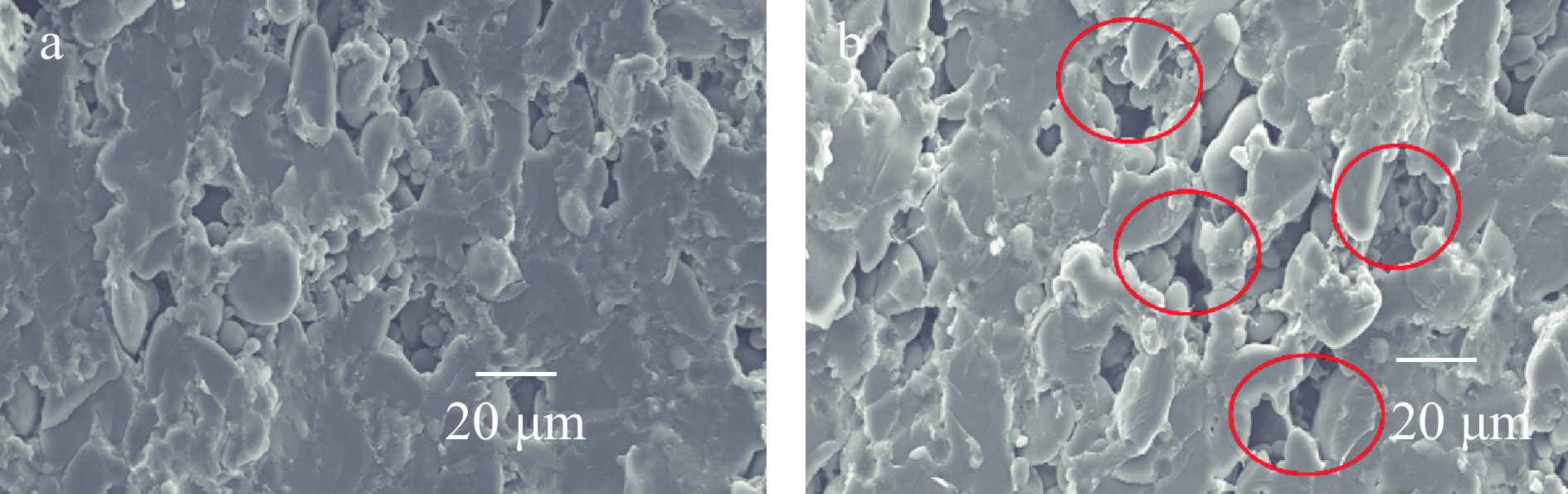

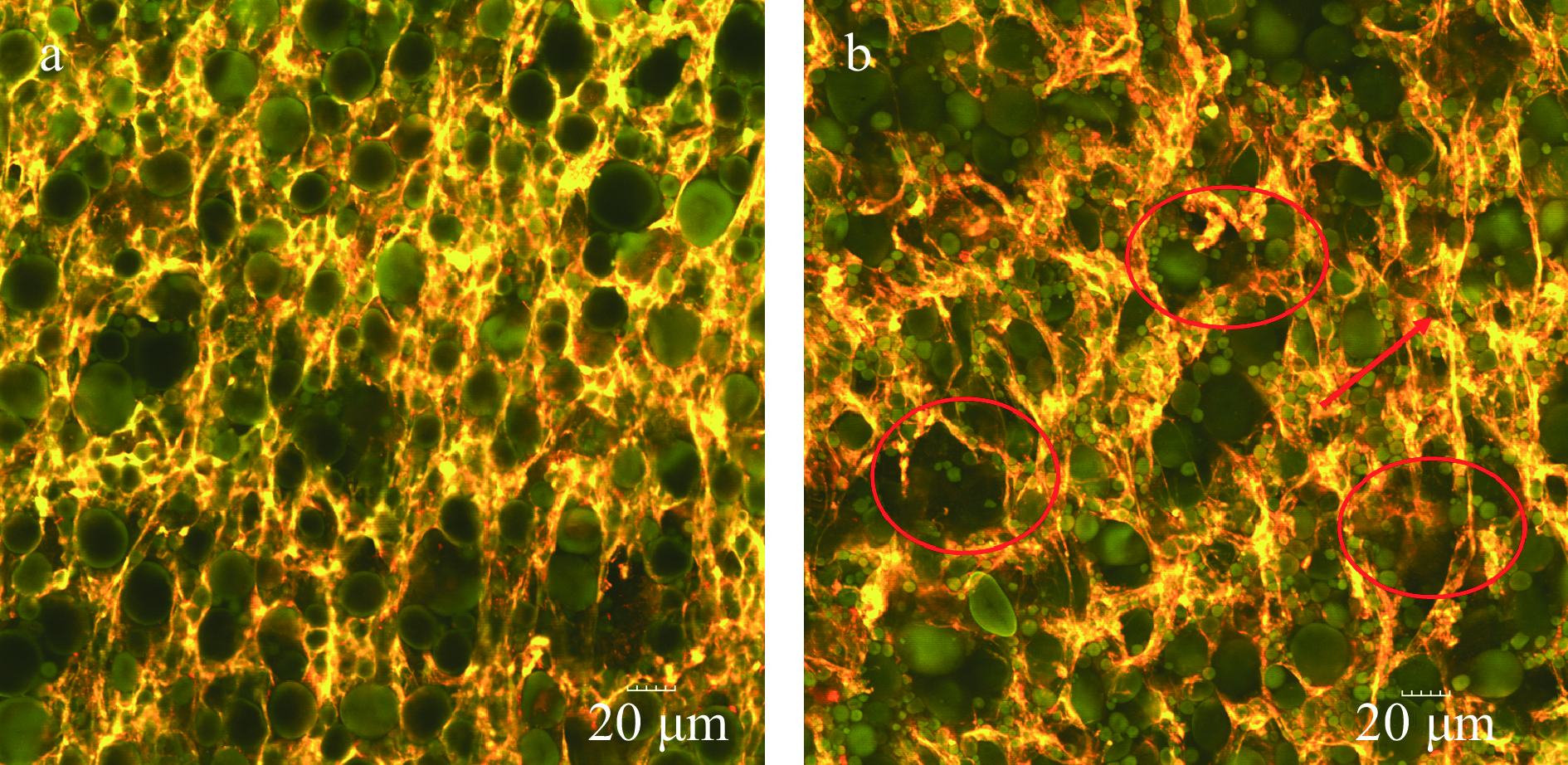

摘要: 为扩大泡泡青蔬菜的利用途径,本研究以泡泡青冻干粉末为原料加工挂面,探讨了泡泡青粉添加后对面粉粉质特性、面团拉伸特性的影响,研究了泡泡青粉、水、食盐添加量对挂面烹调损失、质构等食用品质的影响,优化了泡泡青挂面的加工工艺。结果表明,添加泡泡青蔬菜粉后,粉质特性中的面团形成时间、稳定性下降,吸水率、弱化度上升,面团拉伸特性中的拉伸能量、拉伸阻力、延展度和最大拉伸阻力减小,因此泡泡青粉不利于面团面筋网络结构的形成;优化了泡泡青挂面的加工工艺,泡泡青粉添加量1.30%,加水量36.00%,食盐添加量1.90%时,感官评价为90.12分;通过扫描电镜和激光共聚焦显微镜观察到泡泡青粉阻碍了部分面筋网络的形成,初步解释了挂面质构中硬度和咀嚼性减小、烹调损失增加的变化趋势。Abstract: In order to expand the use of bubble green vegetables, bubble green freeze-dried powder was used as raw material to fabricate dried noodles in this study. The effects of adding the bubble green powder on the flour characteristics, dough tensile properties were discussed. The effects of the additions of green powder, water and salt on the cooking loss, texture and edible quality of the dried noodles were studied, and the processing of bubble green dried noodles was optimized. The results showed that, the dough formation time and stability in the flour characteristics decreased after adding bubble green vegetable powder. Meanwhile, the water absorption rate and weakening degree of the dough increased. The tensile energy, tensile resistance, ductility and maximum tensile resistance in the dough tensile characteristics decreased because of the addition of bubble green vegetables powder. Therefore, the bubble green powder was not conducive to the formation of dough gluten network structure. The processing technology of bubble green dried noodles was optimized. The sensory evaluation of bubble green noodles was 90.12 points when the addition of bubble green powder, water, and salt was 1.30%, 36.00%, and 1.90%, respectively. Blocking effect of bubble green powder on the formation of some gluten networks was observed by scanning electron microscopy and laser confocal microscopy, which preliminarily explained the change trend of decreasing hardness, decreasing chewiness and increasing cooking loss in the texture of dried noodles.

-

Keywords:

- bubble green /

- dried noodles /

- flour characteristics /

- tensile characteristics /

- edible qualities

-

泡泡青是湖北随州的特色蔬菜,地理标志保护产品,又名皱叶黑白菜,口感好、营养丰富,有冬季“蔬菜之王”的美誉[1]。目前,泡泡青主要作为蔬菜食用[2],由于季节性强,不易贮藏等原因,导致泡泡青的利用率、普及程度低。本研究尝试开发含有泡泡青蔬菜粉的挂面,为泡泡青蔬菜的利用提供一条途径。

随着人们健康意识的不断提高,各种蔬菜营养面应运而生。张笑笑等[3]开发了菠菜面条,郭爱平等[4]以南瓜粉为原料加工南瓜面条,另外,还有利用胡萝卜浆[5]、芹菜浆[6],黄豆芽、绿豆芽[7]等蔬菜加工面条的报道。目前,研究内容集中在加工工艺的优化改进,部分研究[8]报道了蔬菜的添加对面团和面条品质的影响,Minarovičová等[9]研究发现加入南瓜粉后面团稳定性和混合耐受指数降低,南瓜粉的添加显著增加面条的烹调损失,当添加10%南瓜粉后,面条烹调损失高达6.6%;张笑笑等[3]发现添加菠菜粉能弥补白面条未含有的维生素、矿物质等营养物质,但菠菜粉添加过量会导致菠菜面条的面筋网络结构的形成受到阻碍,没有嚼劲,口感差;杜传来等[10]发现菠菜粉添加量高于7%时,面条韧性和口感明显下降,此外,杜传来等[10]还研究了芹菜粉,发现过量的芹菜粉会导致面团强度急剧下降,增大面条的烹调损失和断条率。因此,在蔬菜粉(浆)添加量不太大时,蔬菜粉(浆)对面团和面条品质的影响在可以接受的范围内,并且可以为面条提供鲜亮的颜色,提高面条感官评分。

考虑到泡泡青蔬菜的季节性特点和方便运输,本研究以泡泡青冻干粉末为原料加工挂面。在预实验的基础上制备出适合加工挂面的泡泡青蔬菜粉,探讨了泡泡青粉添加后对面粉粉质特性、面团拉伸特性的影响,研究了泡泡青粉、水、食盐添加量对挂面烹调损失、质构等食用品质的影响。通过单因素和响应面试验,优化了泡泡青挂面的加工工艺,并通过扫描电镜和激光共聚焦显微镜观察到的微观结构,初步分析了泡泡青粉影响挂面食用品质的原因,以期获得泡泡青挂面的最佳工艺条件,为泡泡青面制品开发提供参考。

1. 材料与方法

1.1 材料与仪器

泡泡青新鲜蔬菜 湖北金银丰食品有限公司提供;面粉 河北金沙河有限公司;食盐 湖北盐业集团有限公司;异硫氰酸荧光素溶液、罗丹明B 分析纯,天津市科密欧化学试剂有限公司。

Farinograph-E布拉班德粉质仪、Extensograph-E布拉班德拉伸仪 德国布拉班德公司;LGJ-18真空冷冻干燥机 北京松源华兴科技发展有限公司;FKR-240面条机 浙江俊媳妇有限公司;SM-168和面机 深圳市牧人电器五金制品有限公司;SP-16S醒发箱 江苏三麦食品机械有限公司;RH-LHP-300L人工气候箱 常州润华电器有限公司;TA.TOUCH质构仪 上海保圣实业发展有限公司;S-3000N扫描电镜 日本Hitachi公司;FV1200激光共聚焦显微镜 日本Olympus公司。

1.2 实验方法

1.2.1 泡泡青粉制备方法

通过预实验,确定了适合加工挂面的真空冷冻干燥法制备泡泡青蔬菜粉工艺,泡泡青新鲜蔬菜经过清洗晾干表面水分,冷冻后放入真空冷冻干燥机干燥(真空度<100 Pa,−40 ℃)至水分含量7%±0.5%(干基),干燥后的泡泡青蔬菜通过粉碎机粉碎并过100目筛得泡泡青冻干粉末,放入密封袋4 ℃贮藏备用。

1.2.2 总膳食纤维的测定

参考GB 5009.88-2014。

1.2.3 粉质特性的测定

参考 GB/T 14614-2019,面粉中泡泡青粉的添加量分别为:0%、1.0%、2.0%、3.0%、4.0%(质量分数,下同)。

1.2.4 拉伸特性的测定

参考 GB/T 14615-2019,泡泡青粉添加量同1.2.3。

1.2.5 泡泡青挂面工艺

泡泡青粉+面粉+水+食盐→和面(10 min)→醒发(30 ℃,湿度80%,20 min)→压面→切面→干燥(40 ℃,湿度75%,4 h)→成品

将面粉和泡泡青粉按比例混合,得到泡泡青混合粉;将食盐溶于水中,加入混合粉中和面10 min得到絮状面团;然后用保鲜膜包裹面团,于温度为30 ℃,湿度为80%的醒发箱中醒发20 min,再用压面机反复压延成1 mm的光滑面片;将面片用切面机切割成宽2 mm,长18 cm的面条,在40 ℃、湿度75%的人工气候箱干燥4 h,备用。

1.2.6 单因素实验

选择影响泡泡青挂面品质的三个因素加水量、食盐添加量和泡泡青粉添加量,加水量为28%、30%、32%、34%、36%,食盐添加量为0%、1.0%、1.5%、2.0%、2.5%,泡泡青粉添加量为0%、1.0%、2.0%、3.0%、4.0%(均以面粉质量为基准)。单因素实验时,对应其他2个参数固定,分别为食盐添加量1.5%、加水量32%、泡泡青粉添加量2%,泡泡青挂面评价指标为感官评价、烹调损失及质构特性。

1.2.7 响应面试验

在单因素实验的基础上,进行响应面试验设计,以感官评价为指标,用Design-Expert 8.06软件对试验数据进行回归拟合及对模型进行方差分析。采用3因素3水平的Box-Behnken Design试验设计,如表1所示。

表 1 响应面组合因素水平设计Table 1. Response surface combination factor level design因素 水平 −1 0 1 A加水量(%) 32 34 36 B食盐添加量(%) 1 1.5 2 C泡泡青粉添加量(%) 1 2 3 1.2.8 烹调损失率

参考GB/T 40636-2021。

1.2.9 感官评价

参考GB/T 40636-2021。感官评价人员8人,评价之前培训了评价规则和熟悉了评价方法,评分表见表2。

表 2 泡泡青挂面感官评分标准Table 2. Sensory scoring standard of bubble green dried noodles评价项目 分项分值 评价依据 表面状态 15 表面结构细密、光滑为10~15分,表面结构有点粗糙、有轻微裂痕为7~9分,表面粗糙、断裂、变形严重为1~6分 色泽 20 泡泡青挂面为青绿色、色泽均匀为17~20分,暗绿、色泽均匀为 12~16分,褐色、颜色不均匀为1~11分 食味 20 具有比较清新的泡泡青蔬菜特殊风味16~20分,泡泡青特殊风味过重或过淡 10~15分,基本没有泡泡青的特殊风味为1~9分 适口性 25 咀嚼力适中20~25分,偏软或偏硬15~19分,过软或过硬1~14分 粘性 20 咀嚼时爽口、不粘牙为17~20分,较爽口、不粘牙为12~16分,不爽口、发粘为1~11分 1.2.10 质构特性

参考田晓红等[11]等方法并适当修改。取20根挂面,沸水煮至最佳蒸煮时间,取出后用流动自来水反复冲洗3次。实验参数设定如下:采用P/36R探头,测试前速度2 mm/s,测试速度0.8 mm/s,测试后速度0.8 mm/s,应力形变75%,触发力5 g,两次压缩时间间隔5 s,数据采集500 pps。

1.2.11 微观结构

扫描电镜:参考Liu等[12]方法并修改。挂面冷冻干燥48 h后溅射喷金,置于扫描电镜下观察,放大500倍。

激光共聚焦显微镜:参考Qiao等[13]方法并修改。将挂面使用切刀切至2 mm的薄片,首先用异硫氰酸荧光素溶液染色10 min,再用罗丹明B溶液染色5 min;最后用去离子水洗去多余染色液后,盖上盖玻片置于显微镜下观察。激发波长分别为488 nm和543 nm。

1.3 数据处理

采用Excel 2019、Origin Pro 2021和Design-Expert 8.06软件进行数据处理和分析,结果以平均值±标准差表示。

2. 结果与分析

2.1 泡泡青粉对面粉粉质特性的影响

结果见表3,随着泡泡青粉的添加,吸水率有显著性差异(P<0.05),当泡泡青粉添加量≥3.0%时,吸水率达58.65%。这是由于泡泡青粉中膳食纤维含量占35.42%,膳食纤维结构中含有大量的羟基,可与水分子形成氢键,从而使得吸水量增加[14-15]。研究表明,蔬菜中膳食纤维含量40%左右(干基)[16],持水性为5.0~9.0 g/g[17-18]。李燕[19]报道了面团形成时间与面粉的吸水速度有关,面粉吸水速度快,则面团形成时间短。泡泡青粉的添加使面团形成时间和稳定性时间缩短,弱化度上升;泡泡青粉添加量为0~4%,粉质质量指数呈显著性下降(P<0.05),由88.50降至50.50。这是由于泡泡青粉缺少醇溶蛋白和麦谷蛋白,阻碍了面筋网络结构的形成[20-21],使其筋力下降,面团容易流变,加工不易成型,这与杨宇等[22]研究结果一致。所以,若添加泡泡青粉研制面制品,需进行工艺优化,提高其食用品质。

表 3 泡泡青粉对面粉粉质特性的影响Table 3. Effect of bubble green powder on flour characteristics泡泡青粉添加量(%) 吸水率(%) 面团形成时间(min) 稳定性(min) 弱化度(FU) 粉质质量指数 0.0 57.75±0.07a 4.70±0.00c 6.60±0.14c 37.50±0.71a 88.50±0.71d 1.0 58.15±0.07b 4.40±0.14b 5.15±0.35b 58.00±4.24b 69.00±4.24c 2.0 57.95±0.21ab 3.80±0.14a 4.55±0.21b 68.50±3.53c 57.50±0.71b 3.0 58.65±0.07c 3.60±0.14a 3.90±0.28a 78.50±2.12d 54.50±2.12ab 4.0 58.65±0.07c 3.75±0.07a 3.70±0.14a 85.00±2.82d 50.50±0.71a 注:同列字母不同表示差异显著(P<0.05);表4~表7同。 2.2 泡泡青粉对面团拉伸特性的影响

由表4可知,随着泡泡青粉的添加,面团的拉伸能量、拉伸阻力、延展度和最大拉伸阻力也逐渐减小,其中最大拉伸阻力显著性减小(P<0.05)。这说明泡泡青粉的添加使面团筋力变弱,与张庆霞[23]研究一致。这主要是由于泡泡青粉的增加,使面筋蛋白含量相对减少,阻碍了面筋网络结构的形成[24]。当泡泡青粉添加量固定时,随着醒发时间的延长,拉伸阻力增大,这与李燕[19]的研究结果一致。这是由于适当地延长醒发时间,有利于面团内水分的均匀分布,促进蛋白质在氢键的作用下充分结合,同时蛋白质中的-SH被氧化成-S-S-,有利于面筋网络结构的形成,拉伸阻力增大[25-28]。因此,研制泡泡青挂面时,需要改善面团的拉伸特性,从而提高挂面食用品质。

表 4 泡泡青粉对面团拉伸特性的影响Table 4. Effect of bubble green powder on dough tensile properties醒发时间(min) 泡泡青粉添加量(%) 拉伸能量(cm2) 拉伸阻力(BU) 延伸度(mm) 最大拉伸阻力(BU) 45 0.0 73.12±7.34b 412.64±13.26c 145.31±10.31b 418.54±6.19d 1.0 66.23±1.73ab 353.45±7.52b 118.32±5.36a 401.78±5.54cd 2.0 58.43±5.12a 354.12±13.57b 111.42±2.42a 384.75±9.61bc 3.0 64.44±2.63ab 312.78±1.73a 109.48±5.64a 384.63±9.02b 4.0 57.23±0.91a 319.35±10.85a 110.12±5.07a 344.34±9.19a 90 0.0 83.15±3.15c 547.35±15.80c 130.67±3.53b 556.34±7.78d 1.0 83.02±4.95c 520.45±12.45c 111.55±3.54ab 541.23±0.01cd 2.0 72.23±1.40b 505.63±13.31bc 103.46±2.24a 530.45±12.14c 3.0 71.23±3.45b 454.87±3.41b 96.67±10.14a 452.34±2.83b 4.0 61.67±0.71a 390.66±10.07a 96.44±9.49a 420.28±8.50a 135 0.0 78.67±8.79b 538.45±18.81c 128.55±9.90b 555.15±2.95b 1.0 77.87±5.41b 526.46±8.49bc 107.34±4.24a 569.22±4.01b 2.0 72.44±2.41ab 530.15±2.12bc 98.15±2.12a 540.66±17.06b 3.0 65.24±0.07ab 474.36±40.74b 92.89±3.71a 457.33±11.31a 4.0 58.67±8.61a 374.32±10.31a 92.56±9.85a 472.46±49.50a 2.3 单因素实验

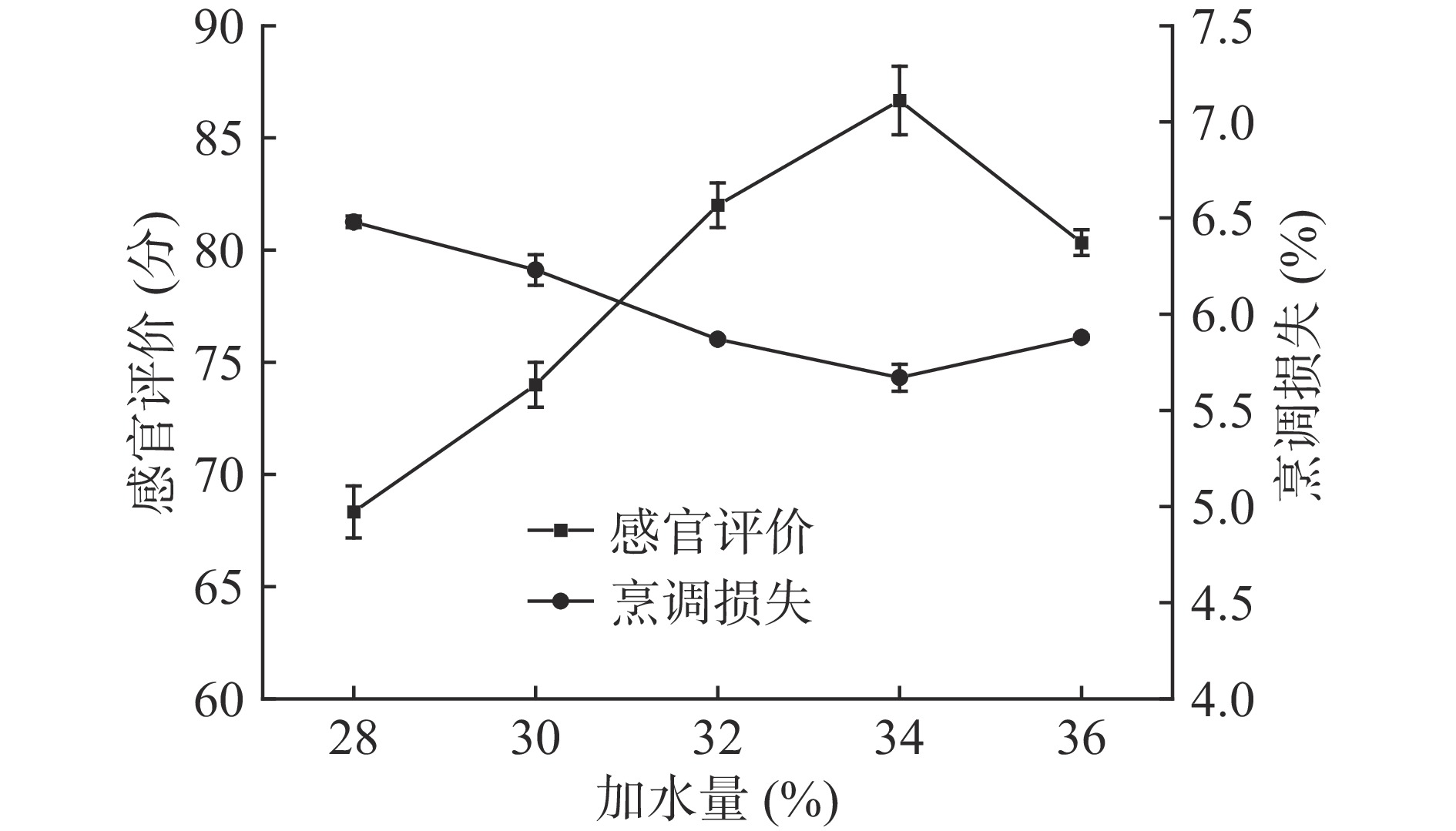

2.3.1 加水量对挂面品质的影响

由图1和表5可知,随着加水量的增加,泡泡青挂面感官评价、硬度和咀嚼性先增大后减小,烹调损失率呈相反趋势。当加水量在34%时,烹调损失率最小,感官评分最高,泡泡青挂面品质较好。水添加量不足时,面絮松散黏性差,影响了面筋网络的形成,不利于压片,甚至可能出现“生粉”;成型的挂面表面粗糙,断条现象比较严重,烹调损失较大;烹调后弹性和咀嚼性较差,影响感官和食用口感[29-30]。水添加量过多时,面团在压延过程中容易粘连辊轮,制成的挂面硬度、感官评分均下降。因为添加泡泡青粉后的面团吸水率比普通面团高,需添加充足的水分才能形成更好的网络结构[31],所以本实验最佳加水量比高飞[32]的研究中普通白挂面的最佳加水量高4%,与粉质特性中面团吸水率随着泡泡青粉添加量增加的结果一致。因此,结合感官评价和烹调损失,选择加水量为32%~36%。

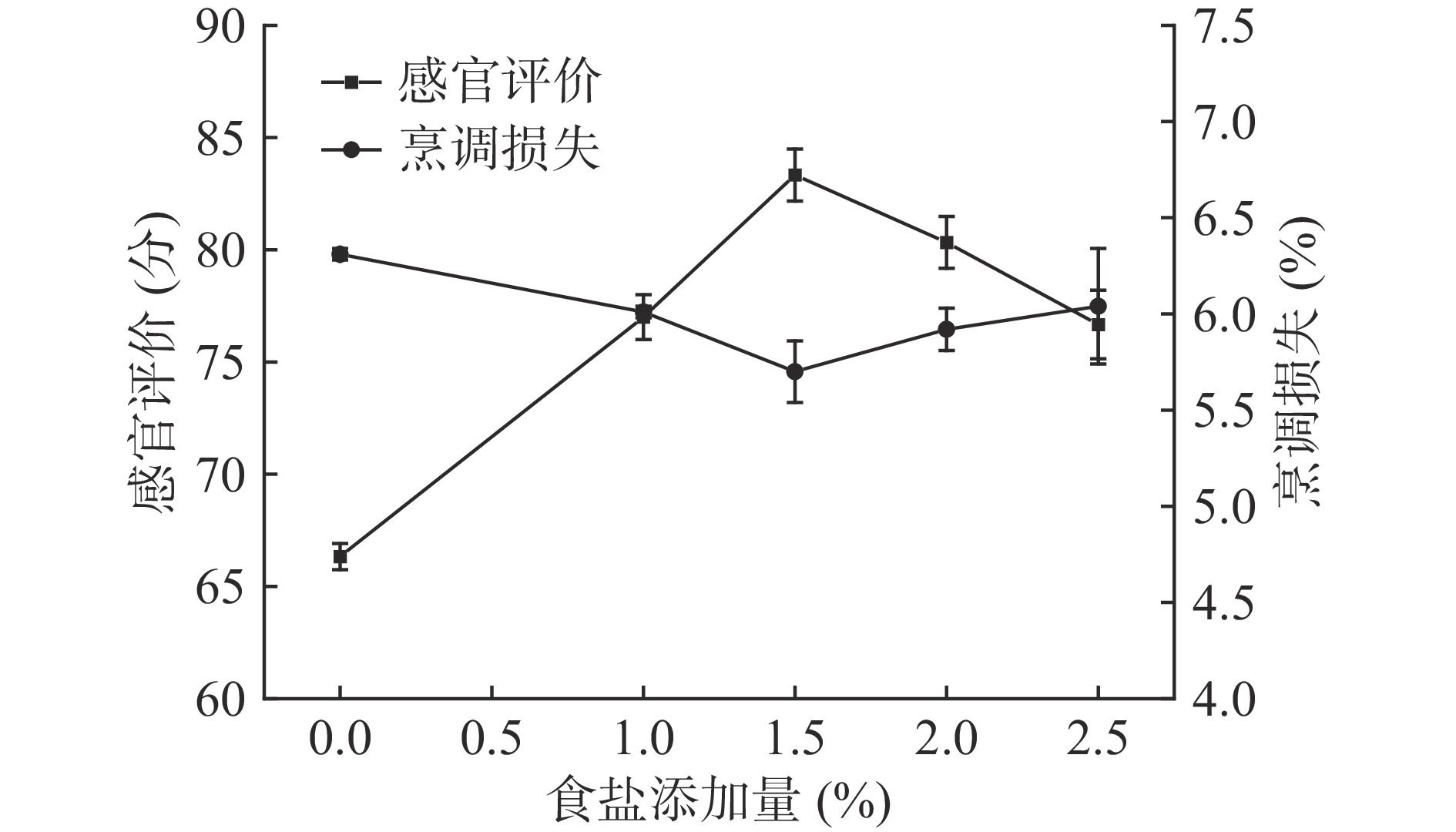

表 5 加水量对泡泡青挂面质构特性的影响Table 5. Effect of water addition on texture characteristics of bubble green dried noodles加水量(%) 硬度(g) 咀嚼性(g) 弹性 回复性 28 1040.02±55.53a 564.30±49.69a 0.77±0.04a 0.37±0.01a 30 1543.29±39.82b 960.08±32.79b 0.83±0.02ab 0.42±0.01b 32 1691.40±47.41c 1112.98±76.49b 0.90±0.02b 0.45±0.01b 34 2078.09±27.85d 1364.04±48.97c 0.88±0.01b 0.44±0.01b 36 1640.56±17.70bc 1035.95±44.11b 0.89±0.02b 0.44±0.01b 2.3.2 食盐对挂面品质的影响

由图2和表6可知,随着食盐添加量的增加,挂面感官评价、硬度和咀嚼性先增加后减小,烹调损失率呈相反的趋势。这是由于食盐的适当添加强化了面筋网络结构,使得挂面的硬度和咀嚼性增加;当添加食盐过多时,过量的食盐与面筋蛋白争夺面团中游离自由水,面筋筋力下降,从而导致硬度和咀嚼性下降[29,33]。食盐添加量为1.5%时,与空白组相比,挂面的烹调损失率显著下降,这可能是因为食盐的阴阳离子与水缔合后形成的水合盐离子与面筋蛋白质表面的电荷结合,提高了蛋白质结合水的能力,使面筋网络结构更加紧实[34-35]。所以,食盐添加量为1.5%时,泡泡青挂面蒸煮后面条口感更筋道,感官评分最高,烹调损失率最小,故选择食盐添加量为1%~2%。

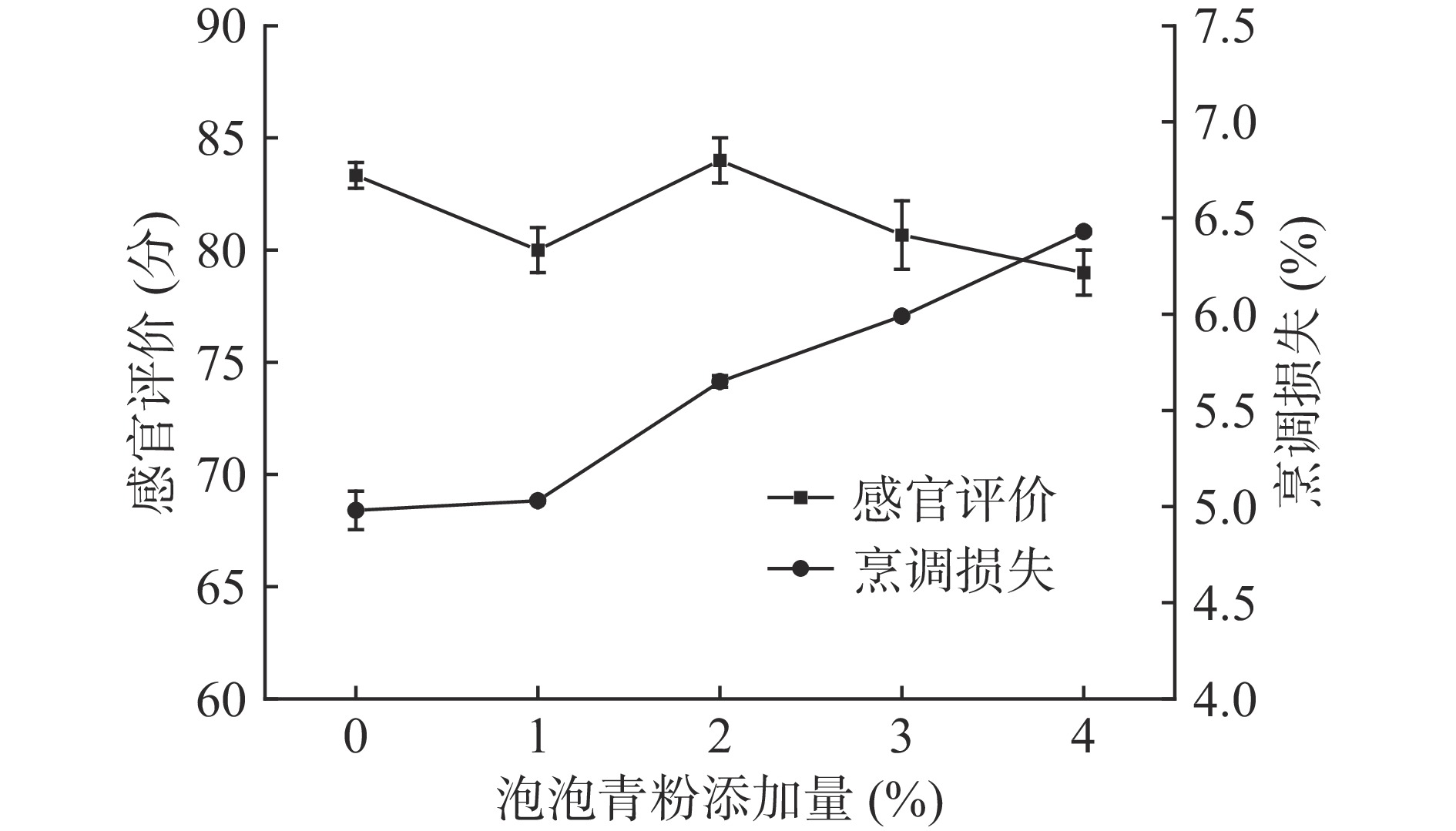

表 6 食盐对泡泡青挂面质构特性影响Table 6. Effect of salt on texture characteristics of bubble green dried noodles食盐添加量(%) 硬度(g) 咀嚼性(g) 弹性 回复性 0.0 1203.26±15.02a 591.35±68.84a 0.84±0.06a 0.40±0.05a 1.0 1455.12±24.83b 939.12±21.20bc 0.91±0.02ab 0.39±0.01a 1.5 1694.93±40.72c 1010.48±25.61c 0.87±0.01ab 0.36±0.03a 2.0 1503.74±18.70b 984.19±61.73bc 0.92±0.05b 0.41±0.03a 2.5 1434.39±65.42b 880.07±35.73b 0.90±0.01ab 0.39±0.01a 2.3.3 泡泡青粉对挂面品质的影响

由图3可知,泡泡青粉添加量为2%时,感官评分最高。泡泡青粉添加量为1%时,挂面中特有的泡泡青蔬菜风味不明显,所以感官评分较低。当泡泡青粉添加量大于2%时,面条表面粗糙,感官评分显著降低,这是因为泡泡青粉添加导致面筋形成不充分、溶出物增多,溶出物附着在表面[36-39]。由图3和表7可以看出,烹调损失率随着泡泡青粉添加量的增加而增加,硬度、咀嚼性、弹性和回复性均呈相反的趋势,与本研究中粉质特性和拉伸特性趋势一致,说明泡泡青粉对面筋网络结构的形成有一定的阻碍作用[29]。结合感官评价,选择泡泡青粉添加量为1%~3%。

表 7 泡泡青添加量对泡泡青挂面质构特性影响Table 7. Effect of the amount of bubble green powder on the texture characteristics of bubble green dried noodles泡泡青添加量(%) 硬度(g) 咀嚼性(g) 弹性 回复性 0.0 1944.61±16.52c 1356.40±16.35d 0.92±0.02e 0.43±0.01a 1.0 1639.29±6.62b 1039.81±16.06c 0.90±0.01de 0.42±0.01a 2.0 1565.25±6.01b 991.16±29.36bc 0.87±0.01bc 0.41±0.02a 3.0 1418.09±32.31a 946.94±24.84b 0.85±0.01ab 0.40±0.03a 4.0 1356.03±43.21a 844.13±20.92a 0.83±0.01a 0.40±0.02a 2.4 响应面试验

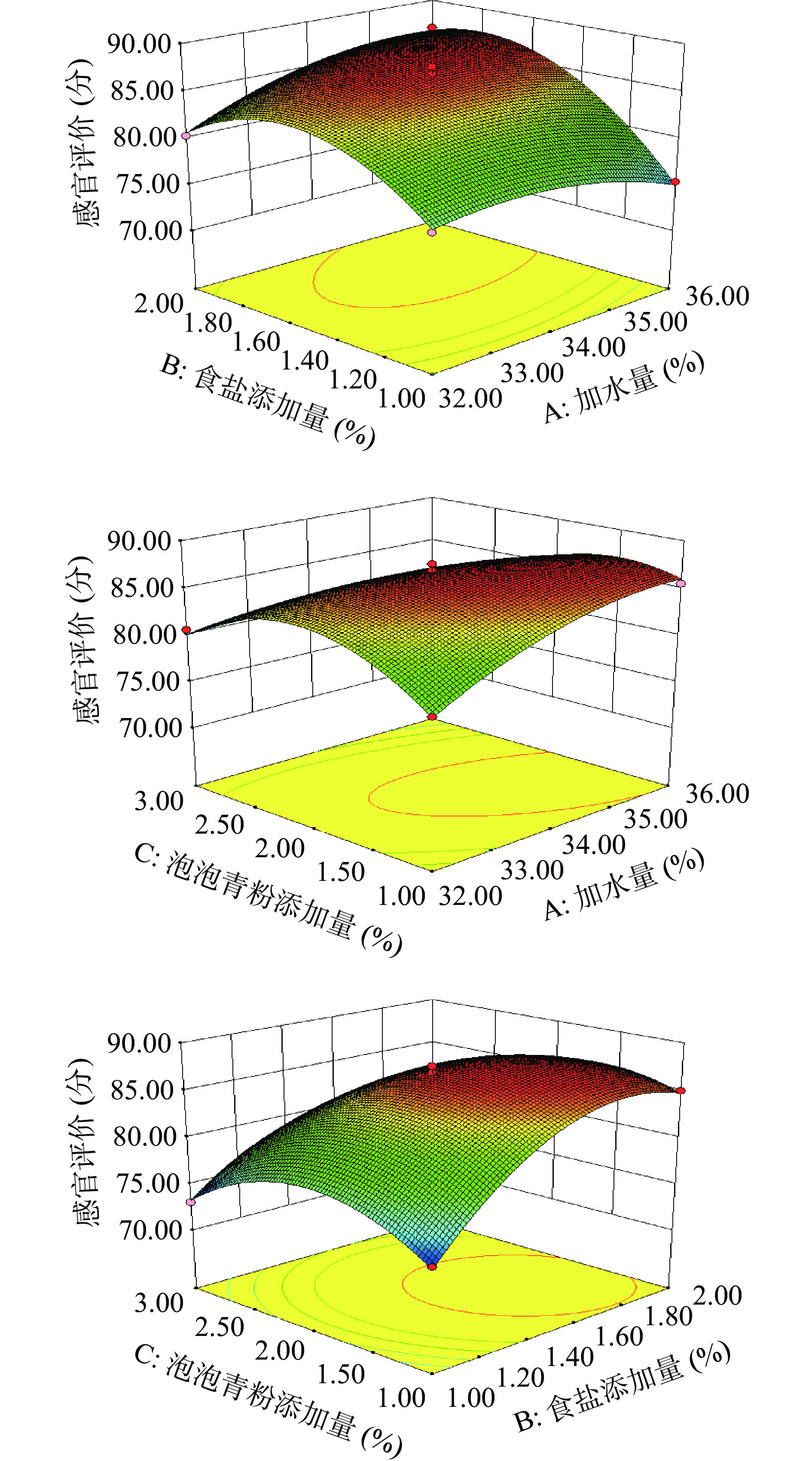

响应面试验结果如表8所示。用Design-Expert 8.06软件对试验结果进行回归拟合,方差分析结果见表9。采用二次多项式拟合[40]得到因素与响应值之间的回归方程:

表 8 响应面试验结果Table 8. Response surface test results实验号 A B C 感官评价(分) 1 1 0 1 75.79 2 0 1 −1 85.03 3 1 0 −1 85.53 4 1 1 0 86.85 5 0 0 0 86.44 6 0 0 0 87.58 7 0 0 0 86.67 8 0 1 1 76.46 9 −1 0 −1 78.79 10 1 −1 0 75.36 11 0 0 0 86.88 12 0 0 0 86.54 13 −1 0 1 80.67 14 0 −1 −1 74.14 15 −1 −1 0 77.57 16 0 −1 1 73.02 17 −1 1 0 80.33 表 9 响应面试验方差分析Table 9. Analysis of variance of response surface experiment变异源 平方和 自由度 均方 F值 P值 模型 444.20 9 49.36 173.07 <0.0001** A-加水量 4.76 1 4.76 16.69 0.0047** B-食盐添加量 102.10 1 102.10 358.04 <0.0001** C-泡泡青粉添加量 38.50 1 38.50 135.01 <0.0001** AB 19.05 1 19.05 66.81 <0.0001** AC 33.76 1 33.76 118.37 <0.0001** BC 13.88 1 13.88 48.66 0.0002** A2 14.90 1 14.90 52.24 0.0002** B2 101.65 1 101.65 356.46 <0.0001** C2 94.84 1 94.84 332.57 <0.0001** 残差 2.00 7 0.29 — — 失拟项 1.17 3 0.39 1.89 0.2729 纯误差 0.83 4 0.21 — — 总误差 446.20 16 — — — 注:**表示极显著(P<0.01)。 Y=86.82+0.77A+3.57B−2.19C+2.18AB−2.90AC−1.86BC−1.88A2−4.91B2−4.75C2

从表9可知,回归模型的P值小于0.0001,即该模型是有效的。模型R2=0.9955,失拟项P=0.2729>0.05,说明其他因素对实验结果干扰小,模型和实验的拟合程度良好,因此响应面分析法所得到二次多项式回归方程模型可信[41],能够用来指导泡泡青挂面加工工艺的优化。此外,由表9和图4可知,影响泡泡青挂面感官评价的各因素的主次顺序:A<C<B,且三个因素与感官评价之间均存在极显著作用(P<0.01)。此外,A2、B2、C2、交互项AB、AC以及BC对感官评价的影响极显著(P<0.01)。

根据拟合的结果进行验证实验,预测参数为加水量36.00%,食盐添加量1.86%,泡泡青粉添加量1.32%,此时感官评价为89.49分。根据此预测参数进行优化实验条件为加水量36.00%,食盐添加量1.90%,泡泡青粉添加量1.30%,感官评价为90.12分,与预测值接近,在合理范围内,进一步验证了回归模型的可靠性。因此,泡泡青挂面最佳配方:加水量为36.00%,食盐添加量为1.90%,泡泡青粉添加量为1.30%。

2.5 微观结构

如图5所示,对照图5a横截面总体上更平滑,大孔隙较少,图5b添加了泡泡青粉后面条(如画红圈部分)孔隙增多,孔径增大,横截面不平滑,由于泡泡青粉中的膳食纤维颗粒较大导致内部孔隙裂缝变多,破坏了面筋网络结构[42],导致泡泡青挂面与白挂面相比烹调损失增加。

![]() 图 5 挂面横截面微观结构电镜图(500×)注:a:白挂面;b:泡泡青挂面;图6同。Figure 5. Electron microscope diagram of cross section microstructure of dried noodles (500×)

图 5 挂面横截面微观结构电镜图(500×)注:a:白挂面;b:泡泡青挂面;图6同。Figure 5. Electron microscope diagram of cross section microstructure of dried noodles (500×)激光共聚焦显微镜微观结构见图6,挂面中淀粉颗粒内部结构由异硫氰酸荧光素优先染为绿色区域,蛋白质由罗丹明B优先染为红色区域,亮黄色区域表示面粉和泡泡青粉中某些可以同时被异硫氰酸荧光素和罗丹明B染色的物质[43]。图6a中白挂面淀粉颗粒均匀地分布在面筋网络结构中,图6b中泡泡青挂面的面筋网络结构部分被撕裂,存在较多断点和孔洞(图中箭头和画圈标注处),说明泡泡青粉中的膳食纤维,在稀释面筋蛋白的同时,会因较强的吸水性和持水性形成空间位阻,影响面筋网络的形成和发育,弱化了面筋网络的强度[44]。在蒸煮时面条中未被包裹的淀粉颗粒易溶于水增加面汤的浑浊度,这也解释了面条的烹调损失率与泡泡青粉添加量成正比。

3. 结论

通过考察泡泡青粉对面粉粉质特性、面团拉伸特性的影响,发现泡泡青粉的添加由0到4%时,面粉粉质特性中的面团形成时间和稳定性显著下降,分别减小了0.95、2.90 min,吸水率、弱化度上升,粉质质量指数呈显著性下降(P<0.05),由88.50降至50.50。同时面团拉伸特性中的拉伸能量、拉伸阻力、延展度和最大拉伸阻力减小。泡泡青挂面的最优加工工艺为:泡泡青粉添加量1.30%,加水量36.00%,食盐添加量1.90%,感官评价最高为90.12分;通过扫描电镜和激光共聚焦显微镜观察到泡泡青粉阻碍了部分面筋网络的形成,初步解释了挂面质构的硬度和咀嚼性减小、烹调损失增加的变化趋势。因此,为了提高泡泡青的利用率,后期可以基于本次的研究结果,对泡泡青面制品进行更有针对性的改良,深入研究面团特性规律和机理。

-

图 5 挂面横截面微观结构电镜图(500×)

注:a:白挂面;b:泡泡青挂面;图6同。

Figure 5. Electron microscope diagram of cross section microstructure of dried noodles (500×)

表 1 响应面组合因素水平设计

Table 1 Response surface combination factor level design

因素 水平 −1 0 1 A加水量(%) 32 34 36 B食盐添加量(%) 1 1.5 2 C泡泡青粉添加量(%) 1 2 3 表 2 泡泡青挂面感官评分标准

Table 2 Sensory scoring standard of bubble green dried noodles

评价项目 分项分值 评价依据 表面状态 15 表面结构细密、光滑为10~15分,表面结构有点粗糙、有轻微裂痕为7~9分,表面粗糙、断裂、变形严重为1~6分 色泽 20 泡泡青挂面为青绿色、色泽均匀为17~20分,暗绿、色泽均匀为 12~16分,褐色、颜色不均匀为1~11分 食味 20 具有比较清新的泡泡青蔬菜特殊风味16~20分,泡泡青特殊风味过重或过淡 10~15分,基本没有泡泡青的特殊风味为1~9分 适口性 25 咀嚼力适中20~25分,偏软或偏硬15~19分,过软或过硬1~14分 粘性 20 咀嚼时爽口、不粘牙为17~20分,较爽口、不粘牙为12~16分,不爽口、发粘为1~11分 表 3 泡泡青粉对面粉粉质特性的影响

Table 3 Effect of bubble green powder on flour characteristics

泡泡青粉添加量(%) 吸水率(%) 面团形成时间(min) 稳定性(min) 弱化度(FU) 粉质质量指数 0.0 57.75±0.07a 4.70±0.00c 6.60±0.14c 37.50±0.71a 88.50±0.71d 1.0 58.15±0.07b 4.40±0.14b 5.15±0.35b 58.00±4.24b 69.00±4.24c 2.0 57.95±0.21ab 3.80±0.14a 4.55±0.21b 68.50±3.53c 57.50±0.71b 3.0 58.65±0.07c 3.60±0.14a 3.90±0.28a 78.50±2.12d 54.50±2.12ab 4.0 58.65±0.07c 3.75±0.07a 3.70±0.14a 85.00±2.82d 50.50±0.71a 注:同列字母不同表示差异显著(P<0.05);表4~表7同。 表 4 泡泡青粉对面团拉伸特性的影响

Table 4 Effect of bubble green powder on dough tensile properties

醒发时间(min) 泡泡青粉添加量(%) 拉伸能量(cm2) 拉伸阻力(BU) 延伸度(mm) 最大拉伸阻力(BU) 45 0.0 73.12±7.34b 412.64±13.26c 145.31±10.31b 418.54±6.19d 1.0 66.23±1.73ab 353.45±7.52b 118.32±5.36a 401.78±5.54cd 2.0 58.43±5.12a 354.12±13.57b 111.42±2.42a 384.75±9.61bc 3.0 64.44±2.63ab 312.78±1.73a 109.48±5.64a 384.63±9.02b 4.0 57.23±0.91a 319.35±10.85a 110.12±5.07a 344.34±9.19a 90 0.0 83.15±3.15c 547.35±15.80c 130.67±3.53b 556.34±7.78d 1.0 83.02±4.95c 520.45±12.45c 111.55±3.54ab 541.23±0.01cd 2.0 72.23±1.40b 505.63±13.31bc 103.46±2.24a 530.45±12.14c 3.0 71.23±3.45b 454.87±3.41b 96.67±10.14a 452.34±2.83b 4.0 61.67±0.71a 390.66±10.07a 96.44±9.49a 420.28±8.50a 135 0.0 78.67±8.79b 538.45±18.81c 128.55±9.90b 555.15±2.95b 1.0 77.87±5.41b 526.46±8.49bc 107.34±4.24a 569.22±4.01b 2.0 72.44±2.41ab 530.15±2.12bc 98.15±2.12a 540.66±17.06b 3.0 65.24±0.07ab 474.36±40.74b 92.89±3.71a 457.33±11.31a 4.0 58.67±8.61a 374.32±10.31a 92.56±9.85a 472.46±49.50a 表 5 加水量对泡泡青挂面质构特性的影响

Table 5 Effect of water addition on texture characteristics of bubble green dried noodles

加水量(%) 硬度(g) 咀嚼性(g) 弹性 回复性 28 1040.02±55.53a 564.30±49.69a 0.77±0.04a 0.37±0.01a 30 1543.29±39.82b 960.08±32.79b 0.83±0.02ab 0.42±0.01b 32 1691.40±47.41c 1112.98±76.49b 0.90±0.02b 0.45±0.01b 34 2078.09±27.85d 1364.04±48.97c 0.88±0.01b 0.44±0.01b 36 1640.56±17.70bc 1035.95±44.11b 0.89±0.02b 0.44±0.01b 表 6 食盐对泡泡青挂面质构特性影响

Table 6 Effect of salt on texture characteristics of bubble green dried noodles

食盐添加量(%) 硬度(g) 咀嚼性(g) 弹性 回复性 0.0 1203.26±15.02a 591.35±68.84a 0.84±0.06a 0.40±0.05a 1.0 1455.12±24.83b 939.12±21.20bc 0.91±0.02ab 0.39±0.01a 1.5 1694.93±40.72c 1010.48±25.61c 0.87±0.01ab 0.36±0.03a 2.0 1503.74±18.70b 984.19±61.73bc 0.92±0.05b 0.41±0.03a 2.5 1434.39±65.42b 880.07±35.73b 0.90±0.01ab 0.39±0.01a 表 7 泡泡青添加量对泡泡青挂面质构特性影响

Table 7 Effect of the amount of bubble green powder on the texture characteristics of bubble green dried noodles

泡泡青添加量(%) 硬度(g) 咀嚼性(g) 弹性 回复性 0.0 1944.61±16.52c 1356.40±16.35d 0.92±0.02e 0.43±0.01a 1.0 1639.29±6.62b 1039.81±16.06c 0.90±0.01de 0.42±0.01a 2.0 1565.25±6.01b 991.16±29.36bc 0.87±0.01bc 0.41±0.02a 3.0 1418.09±32.31a 946.94±24.84b 0.85±0.01ab 0.40±0.03a 4.0 1356.03±43.21a 844.13±20.92a 0.83±0.01a 0.40±0.02a 表 8 响应面试验结果

Table 8 Response surface test results

实验号 A B C 感官评价(分) 1 1 0 1 75.79 2 0 1 −1 85.03 3 1 0 −1 85.53 4 1 1 0 86.85 5 0 0 0 86.44 6 0 0 0 87.58 7 0 0 0 86.67 8 0 1 1 76.46 9 −1 0 −1 78.79 10 1 −1 0 75.36 11 0 0 0 86.88 12 0 0 0 86.54 13 −1 0 1 80.67 14 0 −1 −1 74.14 15 −1 −1 0 77.57 16 0 −1 1 73.02 17 −1 1 0 80.33 表 9 响应面试验方差分析

Table 9 Analysis of variance of response surface experiment

变异源 平方和 自由度 均方 F值 P值 模型 444.20 9 49.36 173.07 <0.0001** A-加水量 4.76 1 4.76 16.69 0.0047** B-食盐添加量 102.10 1 102.10 358.04 <0.0001** C-泡泡青粉添加量 38.50 1 38.50 135.01 <0.0001** AB 19.05 1 19.05 66.81 <0.0001** AC 33.76 1 33.76 118.37 <0.0001** BC 13.88 1 13.88 48.66 0.0002** A2 14.90 1 14.90 52.24 0.0002** B2 101.65 1 101.65 356.46 <0.0001** C2 94.84 1 94.84 332.57 <0.0001** 残差 2.00 7 0.29 — — 失拟项 1.17 3 0.39 1.89 0.2729 纯误差 0.83 4 0.21 — — 总误差 446.20 16 — — — 注:**表示极显著(P<0.01)。 -

[1] 聂启军, 任志勇, 董斌峰, 等. 地方白菜资源随州泡泡青的特性及保护利用[J]. 湖北农业科学,2021,60(S2):306−307. [NIE Q J, REN Z Y, DONG B F, et al. Characteristics, protection and utilization of local cabbage resources Suizhou bubble green[J]. Hubei Agricultural Science,2021,60(S2):306−307. NIE Q J, REN Z Y, DONG B F, et al. Characteristics, protection and utilization of local cabbage resources Suizhou bubble green[J]. Hubei Agricultural Science, 2021, 60 (S2): 306-307.

[2] 戚远斌. 冬季“蔬菜之王”-随州泡泡青[J]. 长江蔬菜,2018(21):23−25. [QIY B. Winter “king of vegetables”-Suizhou bubble green[J]. Changjiang Vegetables,2018(21):23−25. QIY B. Winter “king of vegetables”-Suizhou bubble green[J]. Changjiang Vegetables, 2018(21): 23-25

[3] 张笑笑, 李瑜, 张利苹. 菠菜营养面条工艺研究[J]. 粮食加工,2017,42(1):62−65. [ZHANG X X, LI Y, ZHANG L P. Study on the technology of spinach nutritious noodles[J]. Food Processing,2017,42(1):62−65. ZHANG X X, LI Y, ZHANG L P. Study on the technology of spinach nutritious noodles[J]. Food Processing, 2017, 42 (1): 62-65.

[4] 郭爱平, 温利军, 吴晓伟, 等. 南瓜面条制作工艺的研究[J]. 美食研究,2015,32(4):46−50. [GUO A P, WEN L J, WU XW, et al. Research on the processing technology of pumpkin noodles[J]. Food Research,2015,32(4):46−50. GUO A P, WEN L J, WU XW, et al. Research on the processing technology of pumpkin noodles[J]. Food Research, 2015, 32(4): 46-50.

[5] PRERANA S, ANIPAMA D. Influence of carrot puree incorporation on quality characteristics of instant noodles[J]. Journal of Food Process Engineering,2020,43(3):1−8.

[6] 王艳哲, 董丽萍, 彭辉, 等. 胡萝卜彩色营养功能性面条的工艺研究[J]. 粮油加工,2008(3):87−89. [WANG Y Z, DONG L P, PENG H, et al. Study on the technology of carrot colored nutritious functional noodles[J]. Cereals and Oils Processing,2008(3):87−89. WANG Y Z, DONG L P, PENG H, et al. Study on the technology of carrot colored nutritious functional noodles[J]. Cereals and Oils Processing, 2008(3): 87-89.

[7] 王广峰. 绿芦笋富锗鲜湿面条的研制[J]. 食品科技,2010,35(2):126−128. [WANG G F. Development of green asparagus germanium rich fresh wet noodles[J]. Food Science and Technology,2010,35(2):126−128. WANG G F. Development of green asparagus germanium rich fresh wet noodles[J]. Food Science and Technology, 2010, 35(2): 126-128.

[8] E. SILVA, E. SCHOLTEN, E. VAN DER LINDEN, et al. Influence of swelling of vegetable particles on structure and rheology of starch matrices[J]. Journal of Food Engineering,2012,112(3):168−174.

[9] MINAROVIčOVÁ, L, LAUKOVÁ, M, KOHAJDOVÁ, Z, et al. Effect of pumpkin powder incorporation on cooking and sensory parameters of pasta[J]. Potravinarstvo Slovak Journal of Food Sciences,2017,11(1):373−379.

[10] 杜传来, 石志峰. 蔬菜营养调和面条的研制[J]. 科技创新导报,2014,11(6):202−205. [DU C L, SHI Z F. Development of vegetable nutritional blended noodles[J]. Science and Technology Innovation Guide,2014,11(6):202−205. DU C L, SHI Z F. Development of vegetable nutritional blended noodles[J]. Science and Technology Innovation Guide, 2014, 11(6): 202-205.

[11] 田晓红, 谭斌, 吴娜娜, 等. 马铃薯泥和面对挂面品质的影响[J]. 中国食品学报,2021,21(8):193−199. [TIAN X H, TAN B, WU N N, et al. The influence of mashed potatoes and noodles on the quality of dried noodles[J]. Chinese Journal of Food,2021,21(8):193−199. TIAN X H, TAN B, WU N N, et al. The influence of mashed potatoes and noodles on the quality of dried noodles[J]. Chinese Journal of Food, 2021, 21(8): 193-199.

[12] LIU D X, SONG S X, TAO L, et al. Effects of common buckwheat bran on wheat dough properties and noodle quality compared with common buckwheat hull[J]. LWT,2022,155:112971.

[13] QIAO C C, TIAN X H, WANG L X, et al. Quality characteristics, texture properties and moisture migration of fresh brown rice noodles under different storage and temperatures conditions[J]. Journal of Cereal Science, 2022, 104: 103434.

[14] 孙元琳, 崔璨, 张陇清, 等. 黑小麦全麦粉的面团流变学特性及馒头品质的研究[J]. 食品工业科技,2014,35(10):146−149. [SUN Y L, CUI C, ZHANG L Q, et al. Study on dough rheological properties and steamed bread quality of black wheat whole wheat flour[J]. Food Industry Science and Technology,2014,35(10):146−149. SUN Y L, CUI C, ZHANG L Q, et al. Study on dough rheological properties and steamed bread quality of black wheat whole wheat flour[J]. Food Industry Science and Technology, 2014, 35(10): 146-149.

[15] BUSTOS M C, PÉREZ G T, LEÓN A E. Effect of four types of dietary fiber on the technological quality of pasta[J]. Food Science and Technology International,2011,17(3):213−221.

[16] 任庆, 孙波, 赵晓, 等. 挤压膨化对白菜渣可溶性膳食纤维含量的影响[J]. 食品工业,2014,35(10):96−99. [REN Q, SUN B, ZHAO X, et al. Effect of extrusion on the content of soluble dietary fiber in cabbage residue[J]. Food Industry,2014,35(10):96−99. REN Q, SUN B, ZHAO X, et al. Effect of extrusion on the content of soluble dietary fiber in cabbage residue[J]. Food Industry, 2014, 35(10): 96-99.

[17] 龙芳. 3种提取方式对芹菜可溶性膳食纤维品质特性的影响[J]. 食品科技,2021,46(3):192−198. [LONG F. Effect of three extraction methods on the quality characteristics of soluble dietary fiber in celery[J]. Food Science and Technology,2021,46(3):192−198. LONG F: Effect of three extraction methods on the quality characteristics of soluble dietary fiber in celery[J]. Food Science and Technology, 2021, 46(3): 192-198.

[18] 吴茂玉, 葛邦国, 和法涛, 等. 苦瓜超微膳食纤维粉的研究[J]. 食品科技,2007(3):72−75. [WU M Y, GE B G, HE F T, et al. Study on the superfine dietary fiber powder of balsam pear[J]. Food Science and Technology,2007(3):72−75. doi: 10.3969/j.issn.1005-9989.2007.03.019 WU M Y, GE B G, HE F T, et al. Study on the superfine dietary fiber powder of balsam pear[J]. Food Science and Technology, 2007(3): 72-75. doi: 10.3969/j.issn.1005-9989.2007.03.019

[19] 李燕. 紫淮山全粉对面团流变特性及面条质构特性的影响[J]. 现代面粉工业,2019,33(2):53. [LI Y. Effect of Zihuaishan whole powder on dough rheological properties and noodle texture properties[J]. Modern Flour Industry,2019,33(2):53. LI Y. Effect of Zihuaishan whole powder on dough rheological properties and noodle texture properties [J]. Modern Flour Industry, 2019, 33(2): 53.

[20] 贾玉华. 甘薯渣粉对面团物化特性和面包品质的影响[D]. 上海: 上海海洋大学, 2019. JIA Y H. Effect of sweet potato residue powder on physicochemical properties of dough and bread quality[D]. Shanghai: Shanghai Ocean University, 2019.

[21] TUDORICA C M, KURI V, BRENNAN C S. Nutritional and physicochemical characteristics of dietary fiber enriched pasta[J]. Journal of Agricultural and Food Chemistry,2002,50(2):347−356.

[22] 杨宇, 方丝云, 高嘉星, 等. 添加猴头菇粉对面团流变学特性及挂面品质的影响[J]. 粮食与油脂,2021,34(3):17−20. [YANG Y, FANG S Y, GAO J X, et al. Effect of Hericium erinaceus powder on dough rheological properties and noodle quality[J]. Food and Fat,2021,34(3):17−20. doi: 10.3969/j.issn.1008-9578.2021.03.005 YANG Y, FANG S Y, GAO J X, et al. Effect of Hericium erinaceus powder on dough rheological properties and noodle quality[J]. Food and Fat, 2021, 34(3): 17-20. doi: 10.3969/j.issn.1008-9578.2021.03.005

[23] 张庆霞. 玉米-小麦混合粉面团流变学特性、面条品质及两者相关性[J]. 食品工业科技,2019,40(22):73−76, 81. [ZHANG Q X. Rheological properties of corn wheat mixed flour dough, noodle quality and their correlation[J]. Food Industry Science and Technology,2019,40(22):73−76, 81. ZHANG Q X. Rheological properties of corn wheat mixed flour dough, noodle quality and their correlation[J]. Food Industry Science and Technology, 2019, 40(22): 73-76+81.

[24] 张江宁, 丁卫英, 叶峥, 等. 枣渣-小麦粉面团流变学性质及面条品质的研究[J]. 粮食与油脂,2022,35(7):68−71. [ZHANG J N, DING W Y, YE ZHENG, et al. Study on rheological properties of jujube dregs wheat flour dough and noodle quality[J]. Grain and Oil,2022,35(7):68−71. ZHANG J N, DING W Y, YE ZHENG, et al. Study on rheological properties of jujube dregs wheat flour dough and noodle quality[J]. Grain and Oil, 2022, 35(7): 68-71.

[25] 张月巧, 陈龙, 卢可可, 等. 添加不同粉碎处理香菇粉对面团流变学特性的影响[J]. 食品科学,2015,36(3):12−17. [ZHANG Y Q, CHEN L, LU K K, et al. Effect of adding different crushed mushroom powder on rheological properties of dough[J]. Food Science,2015,36(3):12−17. ZHANG Y Q, CHEN L, LU K K, et al. Effect of adding different crushed mushroom powder on rheological properties of dough[J]. Food Science, 2015, 36(3): 12-17.

[26] 孙粮, 孙君庚, 王充, 等. 余甘果粉对挂面品质的影响研究[J]. 食品科技,2020,45(6):186−191. [SUN L, SUN J G, WANG C, et al. Study on the influence of Yuganguo powder on the quality of dried noodles[J]. Food Science and Technology,2020,45(6):186−191. SUN L, SUN J G, WANG C, et al. Study on the influence of Yuganguo powder on the quality of dried noodles[J]. Food Science and Technology, 2020, 45(6): 186-191.

[27] 吕一鸣, 杨淑凯, 张文占, 等. 挂面品质影响因素研究进展[J]. 粮食加工,2021,46(6):6−11. [LV Y M, YANG S K, ZHANG W Z, et al. Research progress on influencing factors of noodle quality[J]. Food Processing,2021,46(6):6−11. LV Y M, YANG S K, ZHANG W Z, et al. Research progress on influencing factors of noodle quality[J]. Food Processing, 2021, 46(6): 6-11.

[28] 高凤, 郭晓娜, 朱科学. 面粉特性对燕麦挂面品质的影响[J]. 食品与生物技术学报,2021,40(3):46−54. [GAO F, GUO X N, ZHU K X. The influence of flour characteristics on the quality of oat noodle[J]. Journal of Food and Biotechnology,2021,40(3):46−54. GAO F, GUO X N, ZHU K X. The influence of flour characteristics on the quality of oat noodle[J]. Journal of Food and Biotechnology, 2021, 40(3): 46-54.

[29] 陈强, 蒋彩云, 苗文娟, 等. 滁菊特色挂面的工艺优化研究[J]. 食品工业,2019,40(1):42−46. [CHEN Q, JIANG CY, MIAO W J, et al. Research on the process optimization of Chuju special vermicelli[J]. Food Industry,2019,40(1):42−46. CHEN Q, JIANG CY, MIAO W J, et al. Research on the Process Optimization of Chuju Special Vermicelli [J]. Food Industry, 2019, 40(1): 42-46.

[30] 刘启玲, 王庆卫. 不同工艺条件对山木耳挂面产品品质的影响研究[J]. 粮食与油脂,2021,34(2):71−75. [LIU Q L, WANG Q W. Study on the influence of different technological conditions on the quality of agaric dried noodles[J]. Food and Oil,2021,34(2):71−75. LIU Q L, WANG QW. Study on the influence of different technological conditions on the quality of agaric dried noodles[J]. Food and Oil, 2021, 34(2): 71-75.

[31] YUAN H, WANG, YR, ZHANG F, et al. Effects of water addition and noodle thickness on the surface tackiness of frozen cooked noodles[J]. Journal of Food Processing and Preservation,2020,44(9):1−11.

[32] 高飞. 挂面高温干燥系统工艺参数控制及挂面品质研究[D]. 郑州: 河南工业大学, 2010. GAO F. Process parameter control of high temperature drying system for vermicelli and research on vermicelli quality[D]. Zhengzhou: Henan University of Technology, 2010.

[33] 蔡梦迪, 沈春霞, 李玉辉, 等. 食盐对石磨全麦粉及其挂面品质的影响[J]. 食品工业科技,2022,44(3):1−9. [CAI M D, SHEN C X, LI Y H, et al. The influence of salt on the quality of stone milled whole wheat flour and its noodles[J]. Food Industry Science and Technology,2022,44(3):1−9. CAI M D, SHEN C X, LI Y H, et al. The influence of salt on the quality of stone milled whole wheat flour and its noodles[J]. Food Industry Science and Technology, 2022, 44(3): 1-9.

[34] 陈洁, 汪磊, 吕莹果, 卞科. 食盐对烩面面团品质和面筋网络结构的影响[J]. 中国粮油学报,2017,32(4):24−30. [CHEN J, WANG L, LV Y G, BIAN K. The influence of salt on the quality and gluten network structure of stewed flour dough[J]. Chinese Journal of Cereals and Oils,2017,32(4):24−30. doi: 10.3969/j.issn.1003-0174.2017.04.005 CHEN J, WANG L, LV Y G, BIAN K. The influence of salt on the quality and gluten network structure of stewed flour dough[J]. Chinese Journal of Cereals and Oils, 2017, 32(4): 24-30. doi: 10.3969/j.issn.1003-0174.2017.04.005

[35] HU Y F, WEI J J, CHEN Y Y. The impact of salt on the quality of fresh wheat noodle[J]. Acta Universitatis Cabiness. Series E: Food Technology,2017,21(2):1−10.

[36] 胡玲, 张俊, 雷激. 紫甘蓝挂面制备的关键技术研究[J]. 食品科技,2019,44(11):185−191. [HU L, ZHANG J, LEI J. Research on the key technology of preparing purple cabbage noodles[J]. Food Science and Technology,2019,44(11):185−191. HU L, ZHANG J, LEI J. Research on the key technology of preparing purple cabbage noodles[J]. Food Science and Technology, 2019, 44(11): 185-191.

[37] TAZRART K, LAMACCHIA C, et al. Nutrient composition and in vitro digestibility of fresh pasta enriched with Vicia fada[J]. Journal of Food Composition and Analysis,2016,47:8−15.

[38] GULL A, PRASAD K, KUMAR P. Effect of millet flours and carrot pomace on cooking qualities, color and texture of developed pasta[J]. Food Science and Technology,2015,63(1):470−474.

[39] YU SY, LI GH, PAN WC, et al. Effect of pitaya peel powder addition on the phytochemical and textural properties and sensory acceptability of dried and cooked noodles[J]. Journal of Food Processing and Preservation,2020,44(7):1−9.

[40] 王婷, 刘翀, 郑学玲. 发酵空心挂面的配方优化[J]. 食品工业科技,2022,43(12):231−239. [WANG T, LIU C, ZHENG X L. Formulation optimization of fermented hollow hanging noodles[J]. Food Industry Science and Technology,2022,43(12):231−239. WANG T, LIU C, ZHENG X L. Formulation optimization of fermented hollow hanging noodles[J]. Food Industry Science and Technology, 2022, 43(12): 231-239.

[41] 熊添, 蔡芳, 何建军, 等. 响应面优化紫薯生全粉挂面配方工艺[J]. 食品研究与开发,2022,43(19):182−190. [XIONG T, CAI F, HE J J, et al. Response surface optimization of the formula of purple potato raw whole powder vermicelli[J]. Food Research and Development,2022,43(19):182−190. XIONG T, CAI F, HE J J, et al. Response Surface Optimization of the Formula of Purple Potato Raw Whole Powder Vermicelli[J]. Food Research and Development, 2022, 43(19): 182-190.

[42] 葛珍珍, 张圆圆, 陈淑慧, 等. 谷朊粉对面条质构及微观结构的影响[J]. 食品科技,2019,44(9):160−165. [GE Z Z, ZHANG Y Y, CHEN S H, et al. Effect of gluten on noodle texture and microstructur[J]. Food Science and Technology,2019,44(9):160−165. GE Z Z, ZHANG Y Y, CHEN S H, et al. Effect of gluten on noodle texture and microstructur[J]. Food Science and Technology, 2019, 44 (9): 160−165.

[43] 代昕. 绿茶生鲜面的品质调控与保鲜研究[D]. 无锡: 江南大学, 2013. DAI X. Study on quality control and freshness preservation of green tea fresh noodles[D]. Wuxi: Jiangnan University, 2013.

[44] 况玉玉, 杨莎, 张念念, 等. 紫菜粉对面条品质特性及微观结构的影响[J]. 食品工业科技,2022,43(22):111−121. [KUANG Y Y. YANG S, ZHANG N N, et al. Effect of laver powder on noodle quality characteristics and microstructure[J]. Food Industry Science and Technology,2022,43(22):111−121. KUANG Y Y. YANG S, ZHANG N N, et al. Effect of laver powder on noodle quality characteristics and microstructure[J]. Food Industry Science and Technology, 2022, 43(22): 111−121.

下载:

下载:

下载:

下载: