Optimization of Fermentation Processing of Gastrodia elata Oral Liquid with Lactic Acid Bacteria

-

摘要: 本研究以天麻为研究对象,优化复合酶法处理天麻工艺,利用课题组自主分离的植物乳植杆菌STDA6作为发酵菌剂制备发酵天麻口服液,采用正交试验优化乳酸菌发酵天麻口服液的制备工艺。结果表明,将果胶酶、纤维素酶、单宁酶和α-淀粉酶等比例混合后对天麻进行酶解处理,复合酶酶解最佳工艺条件为:料液比(g:mL)1:11,加酶量0.4%,pH4.0,酶解温度50 ℃,酶解时间180 min;乳酸菌发酵天麻口服液的最佳工艺条件为:接种量1×105 CFU/mL,发酵时间12 h,发酵温度37 ℃,蔗糖添加量10%,采用上述工艺制备的乳酸菌发酵天麻口服液乳酸菌活菌数为2×108 CFU/mL,pH为3.5,菌落总数<10 CFU/mL,大肠菌群、霉菌和酵母菌、金黄色葡萄球菌、沙门氏菌均未检出,符合GB/T 31326-2014《植物饮料》的相关要求。Abstract: In this study, Gastrodia elata was treated with compound enzyme, and Lactiplantibacillus plantarum STDA6 was used as fermentation agent to prepare fermented G. elata oral liquid. Orthogonal experiment was used to optimize the preparation process of lactic acid bacteria fermented G. elata oral liquid. The results showed that the optimal process conditions for enzymatic hydrolysis of G. elata were carried out after mixing pectinase, cellulase, tannins and α-amylase, and the optimal process conditions for enzymatic hydrolysis of complex enzymatic hydrolysis were: the ratio of material to liquid (g:mL) was 1:11, the amount of enzyme was 0.4%, the pH value was 4.0, the enzymatic hydrolysis temperature was 50 ℃, the enzymatic hydrolysis time was 180 min. The optimum technological conditions of lactic acid bacteria fermenting G. elata oral liquid were as follows: inoculation amount with 1×105 CFU/mL, fermentation time for 12 h, fermentation temperature at 37 ℃, sucrose addition with 10%. The average number of L. plantarum STDA6 in G. elata oral liquid fermented by lactic acid bacteria was 2×108 CFU/mL, pH value was 3.5, the total number of bacteria was less than 10 CFU/mL and coliform, mold, yeast, Staphylococcus aureus, Salmonella were not been detected, which complied with the relevant requirements of GB/T 31326-2014 ‘Botanical Beverage’.

-

Keywords:

- Gastrodia elata /

- enzymolysis /

- lactic acid bacteria /

- Lactiplantibacillus plantarum

-

天麻(Gastrodia elata)是被子植物纲天麻属兰科草本植物干燥块茎[1],是我国传统名贵中药材,其性辛、温、无毒,富含天麻素、香荚兰素、多糖、氨基酸及微量元素[2]。天麻也是云贵川高原特有的药食同源中药材,拥有悠久的应用历史。《神农本草经》云天麻为上品,“久服益气力,长阴,肥健,轻身,增年”[3];《药性本草》言天麻能“治语多恍惚,善惊失志”[4];《珍珠囊》记载天麻“治风虚眩晕头痛”,故名定风草;清代名医张志聪称赞天麻“功同五芝,力倍五参,为仙家服食上品”。研究发现,天麻中主要含有酚类、苷类、有机酸、甾醇类和多糖类等化合物,主要活性化学成分为天麻素(对羟基苯甲醇1β-D葡萄吡喃糖苷),也是含量最高的有效单体成分[2, 5]。现代药理研究和临床应用表明,天麻具有提高免疫力、镇静止痛、提高耐缺氧力、改善记忆、降血压、抗炎等多种药理作用,对血管性神经性头痛[6]、脑震荡后遗症等有显著疗效[7]。天麻活性化合物天麻素具有多种生理功能,包括镇静催眠[8]、抗惊厥[9]、抗焦虑抑郁[10]、抗炎镇痛[11]、抗氧化[12]、增强记忆和抗衰老[13]、抗病毒和抗肿瘤作用[14],还具有保护神经、调节循环系统[15-16]等功效。

2018年国家卫健委批准天麻作为食药物质试生产,其保健作用及特有的药理特性成为食品领域药食同源研究的热点[17]。目前,有关天麻的研究主要集中在贮藏工艺研究[18]、化学成分分析[19]和药理药效探索[20]等基础研究方面,新型天麻食品饮料研究鲜见报道。乳酸菌是一类能利用可发酵碳水化合物生成乳酸的一类无芽孢、革兰染色阳性细菌的总称,广泛存在于人体内,具有促进营养物质消化吸收、调节肠道菌群、提高机体免疫力等多种益生功能[21-22]。近年来研究表明,乳酸菌发酵剂可以改善药食同源中药材的口感,又能够提升中药材的生物学功效,正日益受到关注[23]。应用乳酸菌发酵天麻,不仅保留天麻原有功能性成分和活性乳酸菌,发酵过程中还可能产生具有生物学活性的功能性代谢产物,从而增加天麻的保健功能[24]。

植物乳植杆菌属于同型乳酸菌,普遍存在于泡菜、酱油和发酵肉制品等传统发酵食品中[25],植物乳植杆菌位于我国《可用于食品的菌种名单》[26]之列,可以作为安全菌株添加于食品中。本研究以天麻为研究对象,采用复合酶法处理天麻,利用课题组自主筛选、在天麻酶解液中生长良好的植物乳植杆菌STDA6作为发酵菌剂,在单因素实验基础上,通过正交试验设计,研发乳酸菌发酵天麻口服液。研究结果可为深入开发天麻及药食同源药材提供理论依据。

1. 材料与方法

1.1 材料与仪器

植物乳植杆菌STDA6 来源于课题组自主分离,已保藏于中国微生物菌种保藏管理委员会普通微生物中心,保藏编号为CGMCC No.20878;天麻 购买于云南省昆明市新螺蛳湾国际商贸城中药材市场;MRS培养基、马铃薯葡萄糖琼脂培养基(PDA)、结晶紫中性红胆盐琼脂培养基(VRBA) 广东环凯微生物科技有限公司;胰蛋白胨 北京兰杰柯科技有限公司;牛肉膏 北京索莱宝科技有限公司;琼脂 广州赛国生物科技有限公司;氯化钠 天津市风船化学试剂科技有限公司;硫酸锰 大连美仑生物技术有限公司;液体石蜡 成都市科隆化学品有限公司;丁二酸钠 大连美仑生物技术有限公司;硼酸 西陇化工股份有限公司;苯酚 天津市化学试剂一厂;磷酸氢二钾 广东光华科技股份有限公司,均为分析纯;α-淀粉酶(30000 U/g)、果胶酶(40000 U/g)、纤维素酶(100000 U/g) 山东隆科特酶制剂有限公司;单宁酶(300 U/g) 南宁庞博生物工程有限公司;碳酸氢钠 南京甘汁园糖业有限公司;柠檬酸 潍坊英轩实业有限公司;蔗糖 昆明多悦多工贸有限公司,均为食品级;试验用水为纯化水。

BSA224S精密分析天平 赛多利斯科学仪器(北京)有限公司;EPED-E2-20TH超纯水仪 南京易普易达科技发展有限公司;DW-86L388J医用低温保存箱 青岛海尔生物医疗股份有限公司;Vorte-5涡旋混合器 江苏海门市麒麟医用仪器厂;UV-5100紫外分光光度计 上海元析仪器有限公司;Sorvall ST 16R高速冷冻离心机 赛默飞世尔科技(中国)有限公司;LDZX-50L立式压力蒸汽灭菌器 上海申安医疗器械厂;SW-CJ-1FD洁净工作台 苏州安泰空气技术有限公司,DHP-9162电热恒温培养箱 上海一恒科学仪器有限公司;FE28 pH计 梅特勒-托利多仪器(上海)有限公司;DHG-9240A电热恒温鼓风干燥箱 上海一恒科学仪器有限公司;HH-6高精度数显恒温水浴锅 上海力辰邦西仪器科技有限公司。

1.2 实验方法

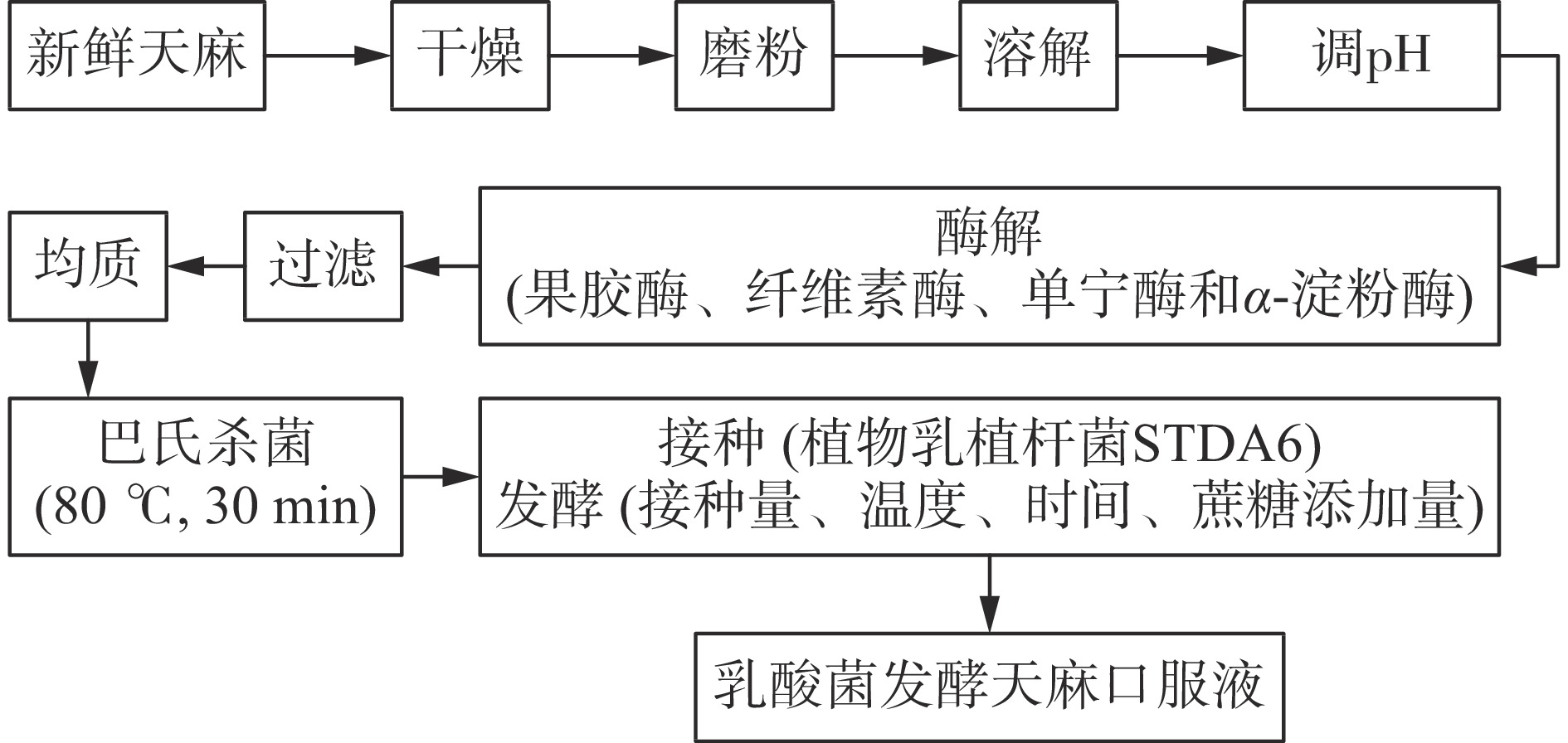

1.2.1 乳酸菌发酵天麻口服液生产工艺流程

参考文献[27]的方法,乳酸菌发酵天麻口服液生产工艺流程如图1。

1.2.2 天麻发酵基液的制备

1.2.2.1 酶解单因素实验

参考文献[27]的方法,以5.0 g天麻粉为基准,料液比1:8(g/mL)、单酶添加量0.3%、pH5.0、酶解温度50 ℃和酶解时间180 min为基准条件,以酶解率为指标,进行单因素实验,优化果胶酶、纤维素酶、单宁酶和ɑ-淀粉酶酶解工艺。

果胶酶酶解天麻单因素实验:分别考察料液比[1:7、1:8、1:9、1:10、1:11(g/mL)]、果胶酶添加量(0.1%、0.2%、0.3%、0.4%、0.5%)、pH(4.0、4.5、5.0、5.5、6.0)、酶解温度(40、45、50、55、60 ℃)和酶解时间(90、120、150、180、210 min)对天麻酶解率的影响。

纤维素酶酶解天麻单因素实验:分别考察料液比[1:6、1:7、1:8、1:9、1:10 (g/mL)]、纤维素酶添加量(0.1%、0.2%、0.3%、0.4%、0.5%)、pH(4.0、4.5、5.0、5.5、6.0)、酶解温度(40、45、50、55、60 ℃)和酶解时间(90、120、150、180、210 min)对天麻酶解率的影响。

单宁酶酶解天麻单因素实验:分别考察料液比[1:7、1:8、1:9、1:10、1:11(g/mL)]、单宁酶添加量(0.1%、0.2%、0.3%、0.4%、0.5%)、pH(4.0、4.5、5.0、5.5、6.0)、酶解温度(50、55、60、65、70 ℃)和酶解时间(60、90、120、150、180 min)对天麻酶解率的影响。

ɑ-淀粉酶酶解天麻单因素实验:分别考察料液比[1:7、1:8、1:9、1:10、1:11(g/mL)]、ɑ-淀粉酶添加量(0.2%、0.3%、0.4%、0.5%、0.6%)、pH(3.0、3.5、4.0、4.5、5.0)、酶解温度(35、40、45、50、55 ℃)和酶解时间(90、120、150、180、210 min)对天麻酶解率的影响。

1.2.2.2 正交试验确定复合酶酶解天麻最佳工艺条件

参考文献[27-29]的方法,复合酶选用等比例混合酶(果胶酶:纤维素酶:单宁酶:α-淀粉酶=1:1:1:1)对天麻进行酶解反应,结合单因素实验结果,选取对酶解率影响较大的4个因素,采用 Design Expert 软件设计L9(34)正交试验方案,进行正交试验,优化天麻酶解条件,酶解正交因素水平见表1。

表 1 正交试验因素水平设计Table 1. Factors and levels design of orthogonal test水平 试验因素 A 料液比

(g/mL)B 复合酶添加量

(%)C 酶解pH D 酶解温度

(℃)1 1:9 0.3 4.0 40 2 1:10 0.4 4.5 50 3 1:11 0.5 5.0 60 1.2.2.3 酶解率的确定

参照叶朋飞等[27]方法,称取天麻粉样品(5 g)进行酶解,酶解液5000 r/min,离心10 min,沉淀80 ℃干燥3 h后称重(m2),根据如下公式计算酶解条件下酶解率:

酶解率(%)=m1−m2m1×100−9.67 式中:m1:天麻样品质量,g ;m2:残渣的质量,g ;9.67:未添加酶处理天麻的酶解率。

1.2.3 乳酸菌发酵天麻口服液的工艺优化

1.2.3.1 植物乳植杆菌STDA6发酵天麻口服液单因素实验

确定天麻酶解条件后,以乳酸菌接种量1×105 CFU/mL、蔗糖添加量8%、发酵温度37 ℃和发酵时间16 h为基准条件,以感官评分为评价指标,分别考察乳酸菌接种量(1×103、1×104、1×105、1×106、1×107 CFU/mL)、发酵温度(33、35、37、39、41 ℃)、发酵时间(8、12、16、20、24 h)和蔗糖添加量(6%、7%、8%、9%、10%)对发酵天麻口服液的影响。

1.2.3.2 植物乳植杆菌STDA6发酵天麻口服液正交试验

结合单因素实验结果,选择乳酸菌接种量、发酵温度、发酵时间和蔗糖添加量四因素,采用Design Expert软件设计L9(34)正交试验方案,进行正交试验,优化乳酸菌发酵天麻的最优条件,正交因素水平见表2。

表 2 正交试验因素水平设计Table 2. Factors and levels design of orthogonal test水平 试验因素 A 接种量

(CFU/mL)B 发酵

时间(h)C 发酵

温度(℃)D 蔗糖

添加量(%)1 1×105 12 33 8 2 1×106 16 35 9 3 1×107 20 37 10 1.2.4 感官评定标准

由10名经过培训的食品专业研究生组成感官评定小组,从颜色与外观、香气、滋味与口感及组织形态四个方面对乳酸菌发酵天麻口服液进行感官评分,评定标准见表3。

表 3 乳酸菌发酵天麻口服液感官评分标准Table 3. Sensory scoring criteria for fermented G. elata oral liquid with lactic acid bacteria感官指标 评分标准 评分区间(分) 颜色与外观

(20分)颜色均匀通亮,呈焦糖色 16~20 颜色不均匀,呈现淡黄色,且略微浑浊 10~15 颜色不均匀(淡黄色或深焦糖色),浑浊 5~9 香气

(20分)有天麻的香气,具有发酵香味,无异味 16~20 天麻的香气较明显,发酵香味稍淡,无异味 10~15 无天麻的香气,发酵香味不足,有异味 5~9 滋味与口感

(30分)酸甜比例适中,发酵酸味浓厚且柔和,

口感细腻滑爽26~30 稍酸或稍甜,发酵酸味较淡,较细腻 20~25 发酵酸味淡,口感较粗糙 16~19 组织状态

(30分)不分层,组织均匀一致,底部无沉淀 26~30 略有分层,组织较细腻,底部无沉淀 20~25 分层较明显,组织粗糙,底部有沉淀 16~19 1.2.5 乳酸菌发酵天麻口服液质量指标测定

1.2.5.1 pH测定

应用pH计测定天麻口服液pH。

1.2.5.2 微生物指标测定

按GB/T 31326-2014相关标准的要求检测[30];菌落总数参照GB 4789.2-2016进行测定[31];大肠菌群参照GB 4789.3-2016进行测定[32];霉菌和酵母菌参照GB 4789.15-2016进行测定[33];金黄色葡萄球菌参照GB 4789.10-2016进行测定[34];沙门氏菌参照GB4789.4-2016进行测定[35];乳酸菌总数参照GB 4789.35-2016进行测定[36]。

1.3 数据处理

所有实验进行3次重复,采用SPSS 19.0软件统计处理数据,使用GraphPad Prism 8.0软件对实验数据进行统计与制图,采用One-way ANOVA进行方差分析和Duncan多重比较进行各数据之间的显著性分析。P<0.05表示各组数据之间的差异具有统计学意义。

2. 结果与分析

2.1 天麻酶解工艺的确定

2.1.1 天麻酶解单因素实验结果

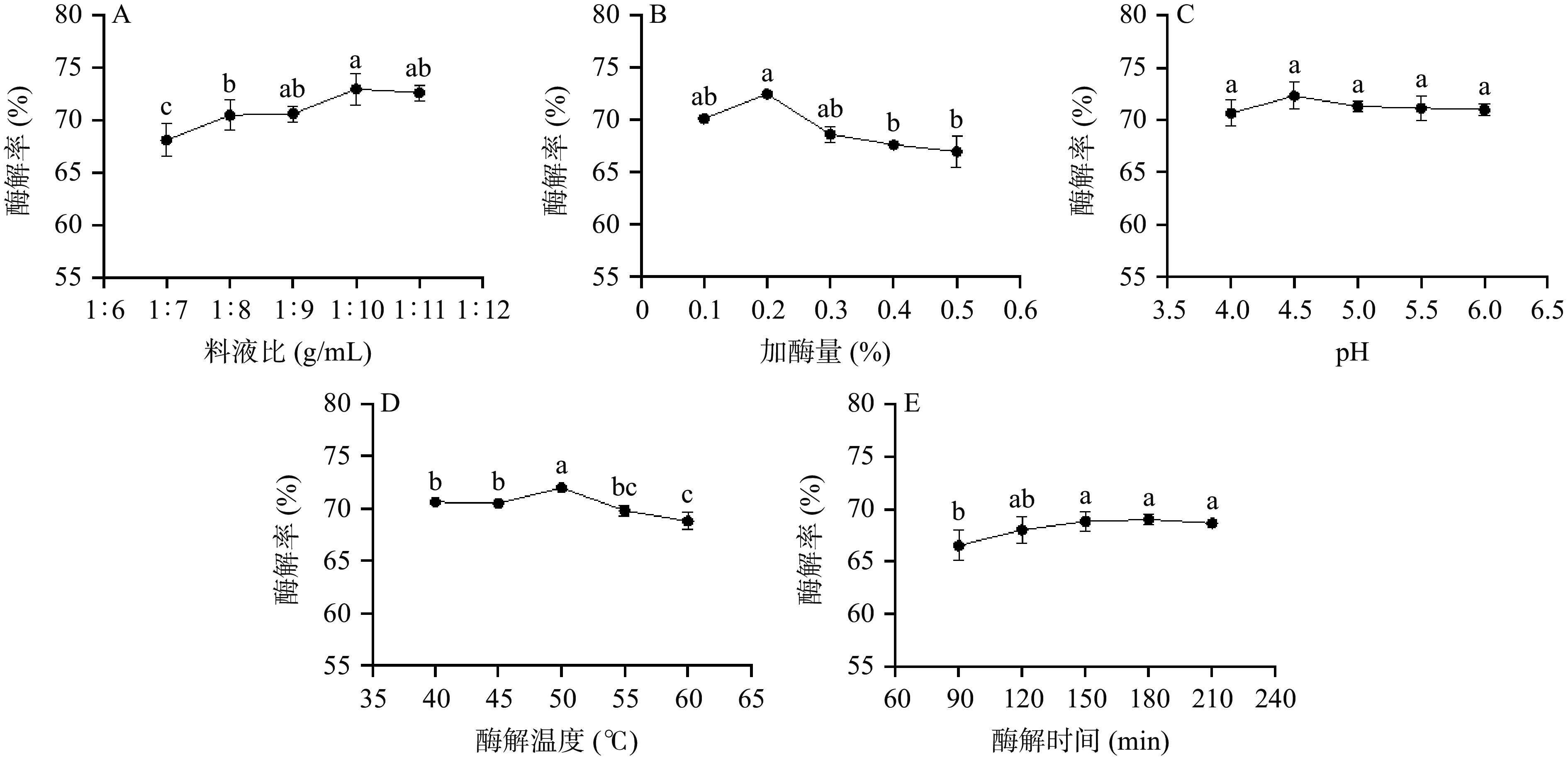

果胶酶较佳酶解条件如图2所示:料液比(g:mL)1:10、加酶量0.2%、pH4.5、50 ℃酶解180 min。

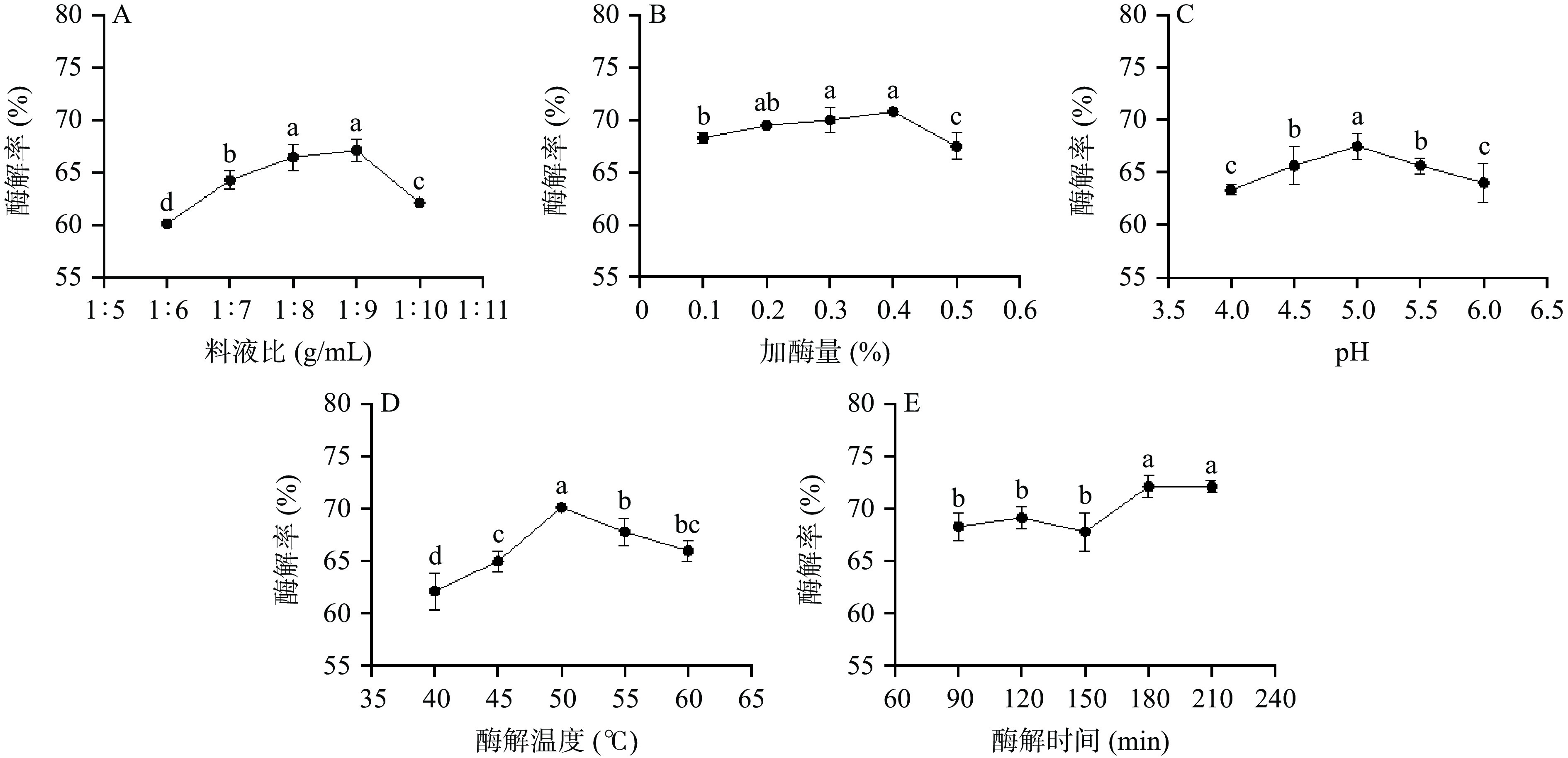

纤维素酶较佳酶解条件如图3所示:料液比(g:mL)1:9、加酶量0.4%、pH5.0、50 ℃酶解180 min。

单宁酶较佳酶解条件如图4所示:料液比(g:mL)1:8、加酶量0.3%、pH4.5、60 ℃酶解150 min。

α-淀粉酶较佳酶解条件如图5所示:料液比(g:mL)1:10、加酶量0.5%、pH4.0、40 ℃酶解150 min。

由上述单因素实验结果可知,在天麻中分别加入果胶酶、纤维素酶、单宁酶和α-淀粉酶,随着料液比、加酶量、pH、酶解温度和酶解时间增加,酶解率总体呈现先上升后下降的趋势。随着料液比的增加,酶解率先增后减,分析结果可能是溶剂体积小时,溶液浓度过大,流动性差,酶与底物接触不充分,致使酶解不完全;溶剂体积大时,溶液稀释,底物浓度降低,影响了反应的进行[37]。随着单酶量的增加,酶解效率提高,酶量继续增加,酶过剩则会导致溶液体系黏度增加,进而限制酶解效率[38]。随着pH升高,酶活性逐渐增强,酶解率提高,pH继续升高酶活性可能受到抑制,酶解率降低。随着酶解温度升高,酶活性逐渐增强,酶解率提高,温度继续升高,酶的稳定性降低,导致酶活性下降,酶解率也随之降低[39]。在一定时间范围内,随着酶解时间延长,酶解率增加,酶解时间继续延长,酶解率趋于稳定,分析原因可能是酶解后期底物基本被酶解完全[40]。果胶酶、纤维素酶的较佳酶解时间为180 min,单宁酶和α-淀粉酶的较佳酶解时间为150 min,综合考虑后选择固定酶解时间为180 min。杨培青[41]蓝莓果渣酵素制备工艺的研究也得出了相似的结果。根据单因素实验结果,果胶酶、纤维素酶、单宁酶和α-淀粉酶的较佳料液比分别是1:10、1:9、1:8和1:10,较佳酶添加量是0.2%、0.4%、0.3%和0.5%,较佳pH分别是4.5、5.0、4.5和4.0,较佳温度分别是50、50、60和40 ℃。综合考虑,选择不同考察因素中相同的最优条件作为正交试验的中心点,即确定料液比1:9、1:10、1:11,复合酶添加量0.3%、0.4%、0.5%,pH4.0、4.5、5.0,酶解温度40、50、60 ℃作为正交因素考察水平。

2.1.2 正交试验确定复合酶酶解天麻最佳工艺条件

根据单因素实验结果,确定料液比(A)、复合酶添加量(B)、酶解pH(C)和酶解温度(D)4个因素,进行4因素3水平的正交试验,正交试验结果见表4。

表 4 正交试验结果(酶解率)Table 4. Results of orthogonal experiments (enzymolysis rate)试验号 因素 酶解率(%) A 料液比 B 复合酶添加量 C 酶解pH D 酶解温度 1 1 1 1 1 70.23 2 2 2 2 1 69.13 3 3 3 3 1 67.83 4 3 2 1 2 70.83 5 2 1 3 2 67.73 6 1 3 2 2 68.83 7 1 2 3 3 66.63 8 2 3 1 3 70.03 9 3 1 2 3 70.03 K1 205.69 207.99 211.09 207.19 K2 206.89 206.59 207.99 207.39 K3 208.69 206.69 202.19 206.69 ¯K1 68.56 69.33 70.36 69.06 ¯K2 68.96 68.86 69.33 69.13 ¯K3 69.56 68.90 67.40 68.90 R 1 0.47 2.96 0.23 注:¯K1、¯K2、¯K3分别是同一水平感官评分的平均值;R极差为同一水平因素的最大值与最小值之差;表6同。 根据各因素显著水平,结合R值大小可以判断影响天麻酶解率的主次因素关系为C>A>B>D,即酶解pH>料液比>复合酶添加量>酶解温度。根据K值,得出理论最佳酶解工艺组合为A3B1C1D2,即料液比1:11、复合酶添加量0.3%、pH4.0、酶解温度50 ℃。在正交试验表中组合A3B2C1D2酶解率最高。将正交试验中由直观分析所得的酶解工艺理论最优和实际最优进行验证实验,结果显示A3B2C1D2(70.93)酶解率高于A3B1C1D2(70.53)。结果与别蒙等[42]和孟然等[43]研究一致,分析可能是因为因素的水平间具有交互作用导致[44]。故选择最佳酶解工艺为料液比1:11、复合酶添加量0.4%、pH4.0、酶解温度50 ℃。由表5中方差分析结果可知,料液比(A)和pH(C)对酶解率影响显著,因素影响大小顺序与表4极差分析结果一致,表明正交试验数据可靠。

表 5 正交试验方差分析(酶解率)Table 5. Anova of orthogonal experiments (enzymolysis rate)方差来源 Ⅲ型平方和 df 均方 F值 Sig. 校正模型 45.884 8 5.735 15.946 0.000 截距 128622.911 1 128622.911 357591.215 0.000 A 4.276 2 2.138 5.944 0.010 B 1.322 2 0.661 1.837 0.188 C 40.073 2 20.036 55.704 0.000 D 0.213 2 0.107 0.296 0.747 误差 6.474 18 0.360 总计 128675.270 27 校正的总计 52.358 26 R2=0.876,R2adj=0.821 2.2 乳酸菌发酵天麻口服液工艺优化

2.2.1 乳酸菌发酵天麻口服液单因素实验结果

通过单因素实验确定了植物乳植杆菌STDA6发酵天麻口服液的工艺条件,结果如图6所示。随着乳酸菌接种量的增加,天麻口服液的感官评分呈现先上升后下降的趋势,分析原因是在一定浓度范围内,增加乳酸菌接种量,对天麻口服液的口感香味方面产生了积极的影响,导致感官评分上升,当接种量达到1×106 CFU/mL时,感官评分达到最大值。随着接种量继续增加,感官评分降低,分析原因可能是接种量过多导致天麻口服液口感偏酸、接受度低[45],这与郑聪等[46]研究余甘子圣女果复合饮料发酵工艺的乳酸菌添加量结果相似,因此确定接种量1×105、1×106、1×107 CFU/mL作为正交因素考察水平。发酵温度对天麻口服液感官评分影响结果显示,随发酵温度升高,感官评分先升高后降低,当发酵温度为35 ℃时感官评分达到最高,分析原因可能是温度会影响乳酸菌的生长的速率和产物形成,当发酵温度为35 ℃时,乳酸菌活性最高,发酵效果最好,天麻口服液口感和滋味最好;温度高于35 ℃时,乳酸菌活性也会随温度升高而下降,发酵效果也随之降低[47]。郗恩光[48]对香蕉金针菇发酵饮料工艺优化研究也得出了相似的结果,因此确定发酵温度33、35、37 ℃作为正交因素考察水平。发酵时间对天麻口服液感官评分影响结果显示,随发酵时间延长,感官评分先升高后降低,分析原因可能是发酵时间太短,发酵风味不明显,发酵时间太长时,乳酸菌增长迅速,使饮料酸涩,口感较差[49],与汪云阳等[50]研究一致。因此确定发酵时间12、16、20 h作为正交因素考察水平。蔗糖添加量对天麻口服液感官评分影响结果显示,随蔗糖添加量增加,感官评分先升高后降低,蔗糖添加量过少或过多时,口感偏酸或偏甜;当蔗糖添加量为9%时,天麻口服液口感适中,感官评分达到最高,因此确定蔗糖添加量8%、9%、10%作为正交因素考察水平。

2.2.2 乳酸菌发酵天麻口服液正交试验结果

根据单因素的实验结果,确定植物乳植杆菌接种量(A)、发酵时间(B)、发酵温度(C)和蔗糖添加量(D)4个因素,进行4因素3水平的正交试验,正交试验结果见表6。根据各因素显著水平,结合R值大小可以判断影响乳酸菌发酵天麻口服液感官评价的主次因素关系为A>B>D>C,即接种量>发酵时间>蔗糖添加量>发酵温度。根据K值,得出最佳工艺组合为A1B1C3D3,即接种量1×105 CFU/mL,发酵时间12 h,发酵温度37 ℃,蔗糖添加量10%。在正交试验表中感官评价得分最高的组合为A3B1C2D3,即接种量为1×107 CFU/mL,发酵时间12 h,发酵温度为35 ℃,蔗糖添加量为10%。将正交试验中由直观分析所得的发酵工艺理论最优和实际最优进行验证实验,结果显示理论最优A1B1C3D3感官评分88.33,高于实际最优A3B1C2D3感官评分85.60。故确定最佳发酵工艺为接种量1×105 CFU/mL,发酵时间12 h,发酵温度37 ℃,蔗糖添加量10%。由表7中方差分析可知,接种量(A)、发酵时间(B)和蔗糖添加量(D)3个因素对感官评分影响显著,因素影响大小顺序与表6 极差分析结果一致,表明正交试验数据可靠。

表 6 正交试验结果(感官评分)Table 6. Results of orthogonal experiments (sensory score)试验号 因素 感官评分

(分)A 接种量 B 发酵时间 C 发酵温度 D 蔗糖添加量 1 2 2 2 1 81.27 2 2 1 3 2 82.57 3 1 1 1 1 84.70 4 1 2 3 3 85.33 5 3 2 1 2 81.40 6 3 1 2 3 85.43 7 1 3 2 2 82.53 8 2 3 1 3 81.40 9 3 3 3 1 81.87 K1 252.56 252.70 247.50 247.84 K2 245.24 248.00 249.23 246.50 K3 248.70 245.80 249.77 252.16 ¯K1 84.19 84.23 82.50 82.61 ¯K2 81.75 82.67 83.08 82.17 ¯K3 82.90 81.93 83.26 84.05 R 2.44 2.30 0.76 1.89 表 7 正交试验方差分析(感官评分)Table 7. Anova of orthogonal experiments (sensory score)方差来源 Ⅲ型平方和 df 均方 F值 Sig. 校正模型 72.127a 8 9.016 11.070 0.000 截距 185754.083 1 185754.083 228074.591 0.000 A 26.916 2 13.458 16.524 0.000 B 24.847 2 12.423 15.254 0.000 C 2.809 2 1.404 1.724 0.206 D 17.556 2 8.778 10.778 0.001 误差 14.660 18 0.814 总计 185840.870 27 校正的总计 86.787 26 R2=0.831,R2adj=0.756 2.3 乳酸菌发酵天麻口服液质量指标检测结果

实验测得乳酸菌发酵天麻口服液pH为3.5,乳酸菌活菌数2×108 CFU/mL,微生物指标:菌落总数<10 CFU/mL,大肠菌群、霉菌和酵母菌、金黄色葡萄球菌、沙门氏菌均未检出,符合GB/T 31326-2014《植物饮料》的相关标准。

3. 讨论

纤维素和果胶是植物细胞壁的主要成分,前人研究发现纤维素酶和果胶酶能够破坏植物细胞壁的完整性[51]。另有研究表明天麻中含有大量酚类物质[2],食用时会有苦涩味。单宁酶在清除植物果实和皮衣中的苦涩味和改善食品原料的适口性方面具有良好的效果,同时可以提高游离氨基酸的得率[52]。天麻中支链淀粉的含量高达90%[53],α-淀粉酶对支链淀粉的酶解速率高于直链淀粉,支链淀粉平均链长更长的淀粉结构更利于经α-淀粉酶酶解[54]。因此,应用α-淀粉酶可以将天麻中的支链淀粉降解为麦芽糖和少量葡萄糖,水溶性增强[55]。目前酶解技术主要应用于提取天麻多糖,而在乳酸菌发酵前酶解天麻的研究鲜见报道。因此,基于多种酶复合使用可有效提升原料利用效率、利于发酵性物质溶出和改善风味的优势。赵敏等[56]制备天麻酵素研究中,采用热水搅拌和加纤维素酶的方法处理天麻原料。朱苗等[57]和李刚凤等[58]制备天麻复合植物饮料中,均采用85 ℃浸提20 min制备天麻浸提液。与上述文献相比,本文采用酶法一步处理,具有工艺简单和节省能源的优势。以天麻单独为基质的发酵产品主要集中在多菌种复配酵素中,乳酸菌发酵天麻产品鲜见报道。已有研究证实植物乳植杆菌在石斛[59]、薏苡仁[60]、葛根[61]等药食同源药材中繁殖性能良好,可能是因为植物乳植杆菌能够耐受和代谢多酚类物质,有学者提出植物乳植杆菌通过对酚类物质的代谢也可能具有维护细胞能量平衡的作用[62]。此外,在纤维素酶和淀粉酶的作用下,天麻中的纤维素和淀粉分解产生的可发酵性糖可被植物乳植杆菌利用进行生长繁殖[63],进一步提高了植物乳植杆菌的发酵性能。本研究发现发酵时间是影响乳酸菌发酵天麻感官品质的主要因素,与范俊华等[64]结果一致。推测随着发酵时间的变化产生的酯类和醛类物质可能对乳酸菌发酵天麻口服液的风味品质形成发挥了重要作用[65],酶解与乳酸菌协同发酵可能有助于酯类等香气物质的产生而促进不良风味物质的转化[66]。在未来研究中,将对乳酸菌发酵天麻口服液的风味物质及功能性进行深入研究,为其产品应用提供理论支持。

4. 结论

本文采用单因素实验和正交试验设计,确定了复合酶果胶酶、纤维素酶、单宁酶和ɑ-淀粉酶酶解天麻最佳工艺条件。本研究以自主分离的植物乳植杆菌STDA6为接种菌剂,乳酸菌发酵天麻口服液的最佳工艺条件为:接种量1×105 CFU/mL,发酵时间12 h,发酵温度37 ℃,蔗糖添加量10%,口感具有天麻的特征风味,酸甜比例适中,发酵酸味浓厚且柔和,细腻滑爽,植物乳植杆菌STDA6活菌数平均值为2×108 CFU/mL,pH3.5。与发酵0 h的活菌数相比,植物乳植杆菌的数量增加了3.3 log CFU/mL,表明其在天麻酶解液中具有优良的增殖活性。

-

表 1 正交试验因素水平设计

Table 1 Factors and levels design of orthogonal test

水平 试验因素 A 料液比

(g/mL)B 复合酶添加量

(%)C 酶解pH D 酶解温度

(℃)1 1:9 0.3 4.0 40 2 1:10 0.4 4.5 50 3 1:11 0.5 5.0 60 表 2 正交试验因素水平设计

Table 2 Factors and levels design of orthogonal test

水平 试验因素 A 接种量

(CFU/mL)B 发酵

时间(h)C 发酵

温度(℃)D 蔗糖

添加量(%)1 1×105 12 33 8 2 1×106 16 35 9 3 1×107 20 37 10 表 3 乳酸菌发酵天麻口服液感官评分标准

Table 3 Sensory scoring criteria for fermented G. elata oral liquid with lactic acid bacteria

感官指标 评分标准 评分区间(分) 颜色与外观

(20分)颜色均匀通亮,呈焦糖色 16~20 颜色不均匀,呈现淡黄色,且略微浑浊 10~15 颜色不均匀(淡黄色或深焦糖色),浑浊 5~9 香气

(20分)有天麻的香气,具有发酵香味,无异味 16~20 天麻的香气较明显,发酵香味稍淡,无异味 10~15 无天麻的香气,发酵香味不足,有异味 5~9 滋味与口感

(30分)酸甜比例适中,发酵酸味浓厚且柔和,

口感细腻滑爽26~30 稍酸或稍甜,发酵酸味较淡,较细腻 20~25 发酵酸味淡,口感较粗糙 16~19 组织状态

(30分)不分层,组织均匀一致,底部无沉淀 26~30 略有分层,组织较细腻,底部无沉淀 20~25 分层较明显,组织粗糙,底部有沉淀 16~19 表 4 正交试验结果(酶解率)

Table 4 Results of orthogonal experiments (enzymolysis rate)

试验号 因素 酶解率(%) A 料液比 B 复合酶添加量 C 酶解pH D 酶解温度 1 1 1 1 1 70.23 2 2 2 2 1 69.13 3 3 3 3 1 67.83 4 3 2 1 2 70.83 5 2 1 3 2 67.73 6 1 3 2 2 68.83 7 1 2 3 3 66.63 8 2 3 1 3 70.03 9 3 1 2 3 70.03 K1 205.69 207.99 211.09 207.19 K2 206.89 206.59 207.99 207.39 K3 208.69 206.69 202.19 206.69 68.56 69.33 70.36 69.06 68.96 68.86 69.33 69.13 69.56 68.90 67.40 68.90 R 1 0.47 2.96 0.23 注:、、分别是同一水平感官评分的平均值;R极差为同一水平因素的最大值与最小值之差;表6同。 表 5 正交试验方差分析(酶解率)

Table 5 Anova of orthogonal experiments (enzymolysis rate)

方差来源 Ⅲ型平方和 df 均方 F值 Sig. 校正模型 45.884 8 5.735 15.946 0.000 截距 128622.911 1 128622.911 357591.215 0.000 A 4.276 2 2.138 5.944 0.010 B 1.322 2 0.661 1.837 0.188 C 40.073 2 20.036 55.704 0.000 D 0.213 2 0.107 0.296 0.747 误差 6.474 18 0.360 总计 128675.270 27 校正的总计 52.358 26 R2=0.876,R2adj=0.821 表 6 正交试验结果(感官评分)

Table 6 Results of orthogonal experiments (sensory score)

试验号 因素 感官评分

(分)A 接种量 B 发酵时间 C 发酵温度 D 蔗糖添加量 1 2 2 2 1 81.27 2 2 1 3 2 82.57 3 1 1 1 1 84.70 4 1 2 3 3 85.33 5 3 2 1 2 81.40 6 3 1 2 3 85.43 7 1 3 2 2 82.53 8 2 3 1 3 81.40 9 3 3 3 1 81.87 K1 252.56 252.70 247.50 247.84 K2 245.24 248.00 249.23 246.50 K3 248.70 245.80 249.77 252.16 84.19 84.23 82.50 82.61 81.75 82.67 83.08 82.17 82.90 81.93 83.26 84.05 R 2.44 2.30 0.76 1.89 表 7 正交试验方差分析(感官评分)

Table 7 Anova of orthogonal experiments (sensory score)

方差来源 Ⅲ型平方和 df 均方 F值 Sig. 校正模型 72.127a 8 9.016 11.070 0.000 截距 185754.083 1 185754.083 228074.591 0.000 A 26.916 2 13.458 16.524 0.000 B 24.847 2 12.423 15.254 0.000 C 2.809 2 1.404 1.724 0.206 D 17.556 2 8.778 10.778 0.001 误差 14.660 18 0.814 总计 185840.870 27 校正的总计 86.787 26 R2=0.831,R2adj=0.756 -

[1] 唐科民. 昭通天麻DNA条形码研究及药用成分分析[D]. 昆明: 云南中医学院, 2013 TANG K M. DNA barcoding research and medicinal compositions analysis of Gastrodia elata[D]. Kunming: University of Yunnan Traditional Chinese Medicine, 2013.

[2] 李云, 王志伟, 刘大会, 等. 天麻化学成分研究进展[J]. 山东科学,2016,29(4):24−29. [LI Y, WANG Z W, LIU D H, et al. Research advances in chemical constituents of Gastrodia elata blume[J]. Shandong Science,2016,29(4):24−29. doi: 10.3976/j.issn.1002-4026.2016.04.006 LI Y, WANG Z W, LIU D H, et al. Research advances in chemical constituents of Gastrodia elata blume [J]. Shandong Science, 2016, 29(4): 24-29. doi: 10.3976/j.issn.1002-4026.2016.04.006

[3] 单锋, 周良云, 蒋长顺, 等. 天麻的食用历史及发展建议[J]. 中国食品药品监管,2021(3):110−115. [DAN F, ZHOU L Y, JIANG C S, et al. History and development recommendations of Gastrodia elata[J]. China Food and Drug Administration,2021(3):110−115. DAN F, ZHOU L Y, JIANG C S, et al. History and development recommendations of Gastrodia elata[J]. China Food and Drug Administration, 2021(3): 110-115.

[4] 邵明. 天麻小档案[J]. 饮食科学,2008(8):22. [SHAO M. Gastrodia small archives[J]. Diet Science,2008(8):22. SHAO M. Gastrodia small archives[J]. Diet Science, 2008(8): 22.

[5] 张建军. 天麻镇静安神作用的最新研究进展[C]//中国药理学会第十次全国学术会议专刊. 天津: 中国药理学通报编辑部, 2009: 151−152 ZHANG J J. The latest research progress on the calming effect of Gastrodia[C]//The 10th National Academic Conference of the Chinese Pharmacological Society. Tianjin: Editorial Department of Chinese Pharmacological Bulletin, 2009: 151−152.

[6] WANG P H, ZHAO L X, WAN J Y, et al. Pharmacological characterization of a novel gastrodin derivative as a potential anti-migraine agent[J]. Fitoterapia,2016,109:52−57. doi: 10.1016/j.fitote.2015.12.007

[7] 王玉悦, 陈维佳, 包海鹰. 天麻资源及其开发利用的研究进展[J]. 人参研究,2019,31(4):52−62. [WANG Y J, CHEN W J, BAO H Y, et al. Research progress on Gastrodia elata resources and its development and utilization[J]. Ginseng Research,2019,31(4):52−62. doi: 10.19403/j.cnki.1671-1521.2019.04.015 WANG Y J, CHEN W J, BAO H Y, et al. Research progress on Gastrodia elata resources and its development and utilization[J]. Ginseng Research, 2019, 31(4): 52-62. doi: 10.19403/j.cnki.1671-1521.2019.04.015

[8] WU J Y, WU B C, TANG C L, et al. Analytical techniques and pharmacokinetics of Gastrodia elata blume and its constituents[J]. Molecules,2017,22(7):1137. doi: 10.3390/molecules22071137

[9] 汤永红. 中药天麻的鉴定及药理作用探讨[J]. 中国农村卫生,2019,11(19):75−76. [TANG Y H. Identification and pharmacological effects of Chinese medicine Gastrodia[J]. China Rural Health,2019,11(19):75−76. doi: 10.3969/j.issn.1674-361X.2019.19.044 TANG Y H. Identification and pharmacological effects of Chinese medicine Gastrodia[J]. China Rural Health, 2019, 11(19): 75-76. doi: 10.3969/j.issn.1674-361X.2019.19.044

[10] 付亚轩, 孟宪钰, 李明超, 等. 天麻抗抑郁药效物质及其作用机制研究进展[J]. 中草药,2020,51(21):5622−5630. [FU Y X, MENG X Y, LI M C, et al. Research progress on antidepressant agents of Gastrodia and their mechanism of action[J]. Chinese Medicinal Materials,2020,51(21):5622−5630. doi: 10.7501/j.issn.0253-2670.2020.21.028 FU Y X, MENG X Y, LI M C, et al. Research progress on antidepressant agents of Gastrodia and their mechanism of action[J]. Chinese Medicinal Materials, 2020, 51(21): 5622-5630. doi: 10.7501/j.issn.0253-2670.2020.21.028

[11] PENG Z W, WANG S Q, CHEN G J, et al. Gastrodin alleviates cerebral ischemic damage in mice by improving anti-oxidant and anti-inflammation activities and inhibiting apoptosis pathway[J]. Neurochemical Research,2015,40(4):661−673. doi: 10.1007/s11064-015-1513-5

[12] 李德柱, 张兴国. 天麻抗氧化成分的提取工艺优化及其抗氧化活性研究[J]. 现代中药研究与实践,2019,33(6):46−49. [LI D Z, ZHANG X G. Study on the extraction process of the anti-oxidation components of Gastrodia elata and its antioxidative activity[J]. Research and Practice on Chinese Medicines,2019,33(6):46−49. doi: 10.13728/j.1673-6427.2019.06.011 LI D Z, ZHANG X G. Study on the extraction process of the anti-oxidation components of Gastrodia elata and its antioxidative activity[J]. Research and Practice on Chinese Medicines, 2019, 33(6): 46-49. doi: 10.13728/j.1673-6427.2019.06.011

[13] SONG E, CHUNG H, SHIM E, et al. Gastrodia elata blume extract modulates antioxidant activity and ultraviolet A-irradiated skin aging in human dermal fibroblast cells[J]. Journal of Medicinal Food,2016,19(11):1057−1064. doi: 10.1089/jmf.2016.3722

[14] ZHAN H D, ZHOU H Y, SUI Y P, et al. The rhizome of Gastrodia elata blume-An ethnopharmacological review[J]. Ethnopharmacol,2016,189:361−385. doi: 10.1016/j.jep.2016.06.057

[15] 柳威, 邓林华, 祁东利, 等. 天麻及其有效成分的药理作用概述[J]. 中药药理与临床,2021,37(4):240−244,12. [LIU W, DENG L H, QI D L, et al. Overview of the pharmacological effects of Gastrodia and its active ingredients[J]. Pharmacology and Clinics of Chinese Materia Medica,2021,37(4):240−244,12. doi: 10.13412/j.cnki.zyyl.20210120.003 LIU W, DENG L H, QI D L, et al. Overview of the pharmacological effects of Gastrodia and its active ingredients[J]. Pharmacology and Clinics of Chinese Materia Medica, 2021, 37(4): 240-244, 12. doi: 10.13412/j.cnki.zyyl.20210120.003

[16] 南一楠, 王少卿. 天麻素对神经系统疾病作用的基础研究进展[J]. 中西医结合心脑血管病杂志,2020,18(22):3811−3813. [NAN Y N, WANG S Q. Advances in basic research on the effects of gastrodin on neurological diseases[J]. Chinese Journal of Integrative Medicine on Cardio-/Cerebrovascular Disease,2020,18(22):3811−3813. doi: 10.12102/j.issn.1672-1349.2020.22.021 NAN Y N, WANG S Q. Advances in basic research on the effects of gastrodin on neurological diseases[J]. Chinese Journal of Integrative Medicine on Cardio-/Cerebrovascular Disease, 2020, 18(22): 3811-3813. doi: 10.12102/j.issn.1672-1349.2020.22.021

[17] 曹森, 雷霁卿, 吉宁, 等. 鲜天麻采后生理品质变化规律及病原菌鉴定的研究[J]. 食品工业科技,2019,40(17):285−293. [CAO S, LEI J Q, JI N, et al. Study on the physiological quality changes and identification of pathogen pathogenicity of Gastrodia elata after harvest[J]. Science and Technology of Food Industry,2019,40(17):285−293. doi: 10.13386/j.issn1002-0306.2019.17.047 CAO S, LEI J Q, JI N, et al. Study on the physiological quality changes and identification of pathogen pathogenicity of Gastrodia elata after harvest[J]. Science and Technology of Food Industry, 2019, 40(17): 285-293. doi: 10.13386/j.issn1002-0306.2019.17.047

[18] 管金杰, 张公信, 王承潇, 等. 天麻贮藏工艺研究[J]. 中药材,2022(4):842−849. [GUAN J J, ZHANG G X, WANG C X, et al. Study on the preservation process of Gastrodiae rhizoma[J]. Journal of Chinese Medicinal Materials,2022(4):842−849. GUAN J J, ZHANG G X, WANG C X, et al. Study on the preservation process of Gastrodiae rhizoma[J]. Journal of Chinese Medicinal Materials, 2022(4): 842-849.

[19] 于涵, 张俊, 陈碧清, 等. 天麻化学成分分类及其药理作用研究进展[J]. 中草药,2022,53(17):5553−5564. [YU H, ZHANG JUN, CHEN B Q, et al. Research progress on classification of chemical constituents from Gastrodia elata and their pharmacological effects[J]. Chinese Medicinal Materials,2022,53(17):5553−5564. doi: 10.7501/j.issn.0253-2670.2022.17.033 YU H, ZHANG JUN, CHEN B Q, et al. Research progress on classification of chemical constituents from Gastrodia elata and their pharmacological effects[J]. Chinese Medicinal Materials, 2022, 53(17): 5553-5564. doi: 10.7501/j.issn.0253-2670.2022.17.033

[20] 冯彦. 藏药天麻的药理作用研究进展[J]. 中国民族医药杂志,2022,28(4):59−60. [FENG Y. Research progress on the pharmacological effects of Tibetan medicine Gastrodia elata[J]. Journal of Medicine & Pharmacy of Chinese Minorities,2022,28(4):59−60. doi: 10.3969/j.issn.1006-6810.2022.04.025 FENG Y. Research progress on the pharmacological effects of Tibetan medicine Gastrodia elata. [J]. Journal of Medicine & Pharmacy of Chinese Minorities, 2022, 28(4): 59-60. doi: 10.3969/j.issn.1006-6810.2022.04.025

[21] KIM S K, GUEVARRA R B, KIM Y T, et al. Role of probiotics in human gut microbiome-associated diseases[J]. Journal of Microbiology and Biotechnology,2019,29(9):1335−1340. doi: 10.4014/jmb.1906.06064

[22] TSAI Y T, CHENG P C, PAN T M. The immunomodulatory effects of lactic acid bacteria for improving immune functions and benefits[J]. Applied Microbiology and Biotechnology,2013,96(4):853−862.

[23] 王静涵, 张斯童, 滕利荣, 等. 益生菌发酵中药的研究现状及产品开发[J]. 食品工业科技,2020,41(14):337−343, 348. [WANG J H, ZHANG S T, TENG L R, et al. Research status and product development of probiotic fermentation of traditiona Chinese medicine[J]. Science and Technology of Food Industry,2020,41(14):337−343, 348. doi: 10.13386/j.issn1002-0306.2020.14.054 WANG J H, ZHANG S T, TENG L R, et al. Research status and product development of probiotic fermentation of traditiona Chinese medicine[J]. Science and Technology of Food Industry, 2020, 41(14): 337-343, 348. doi: 10.13386/j.issn1002-0306.2020.14.054

[24] 黄先敏, 孙建美, 范莉, 等. 天麻对乳酸菌发酵过程中氨基酸代谢的影响研究[J]. 昭通学院学报,2021,43(5):6−12. [HUANG X M, SUN J M, FAN L, et al. Effect of Gastrodia elata Blume on amino acid metabolism during fermentation of lactic acid bacteria[J]. Journal of Zhaotong University,2021,43(5):6−12. doi: 10.3969/j.issn.1008-9322.2021.05.003 HUANG X M, SUN J M, FAN L, et al. Effect of Gastrodia elata Blume on amino acid metabolism during fermentation of lactic acid bacteria[J]. Journal of Zhaotong University, 2021, 43(5): 6-12. doi: 10.3969/j.issn.1008-9322.2021.05.003

[25] 王鸿蕉, 蔡昀洁, 岳明祥, 等. 植物乳杆菌的抑菌性能及其影响因素研究进展[J]. 食品研究与开发,2022,43(14):212−218. [WANG H J, CAI Y J, YUE M X, et al. Antimicrobial properties of Lactobacillus plantarum and their influencing factors[J]. Food Research and Development,2022,43(14):212−218. doi: 10.12161/j.issn.1005-6521.2022.14.027 WANG H J, CAI Y J, YUE M X, et al. Antimicrobial properties of Lactobacillus plantarum and their influencing factors[J]. Food Research and Development, 2022, 43(14): 212-218. doi: 10.12161/j.issn.1005-6521.2022.14.027

[26] 杨晓晶. 《可用于食品的菌种名单》《可用于婴幼儿食品的菌种名单》调整更新[N]. 中国食品报, 2021-11-01(6) YANG X J. The list of cultures that can be used in food and the list of cultures that can be used for infant food were adjusted and updated[N]. China Food News, 2021-11-01(6).

[27] 叶朋飞, 罗程, 黄丝艳, 等. 乳酸菌发酵云参酵素的工艺优化及其功能研究[J]. 云南农业大学学报(自然科学),2019,34(5):896−905. [YE P F, LUO C, HUANG S Y, et al. Optimization and functional study on Codonoposis bulleyana forrest ex diels ferment with lactic acid bacteria[J]. Journal of Yunnan Agricultural University (Natural Science),2019,34(5):896−905. doi: 10.12101/j.issn.1004-390X(n).201903009 YE P F, LUO C, HUANG S Y, et al. Optimization and functional study on Codonoposis bulleyana forrest ex diels ferment with lactic acid bacteria[J]. Journal of Yunnan Agricultural University (Natural Science), 2019, 34(5): 896-905. doi: 10.12101/j.issn.1004-390X(n).201903009

[28] 王占一, 廖成斌, 公金艳, 等. 复合酶提取石榴幼果总黄酮工艺优化及其抑制α-葡萄糖苷酶活性[J]. 食品工业科技,2019,40(9):178−183, 188. [WANG Z Y, LIAO C B, GONG J Y, et al. Complex enzymatic extraction of total flavonoids from pomegranate fruitlets and their anti-α-glucosidase activity[J]. Science and Technology of Food Industry,2019,40(9):178−183, 188. WANG Z Y, LIAO C B, GONG J Y, et al. Complex enzymatic extraction of total flavonoids from pomegranate fruitlets and their anti-α-glucosidase activity[J]. Science and Technology of Food Industry, 2019, 40(9): 178-183, 188.

[29] 扎罗, 刘振东, 王波, 等. 复合酶法提取西藏金耳粗多糖工艺研究[J]. 轻工科技,2018,34(1):23−25. [ZHA L, LIU Z D, WANG B, et al. Study on the process of extracting coarse polysaccharides from Tibetan golden ear by complex enzyme method[J]. Guangxi Journal of Light Industry,2018,34(1):23−25. ZHA L, LIU Z D, WANG B, et al. Study on the process of extracting coarse polysaccharides from Tibetan golden ear by complex enzyme method[J]. Guangxi Journal of Light Industry, 2018, 34(1): 23-25.

[30] 国家标准化管理委员会, 国家质量监督检验检疫总局. GB/T 31326-2014 植物饮料[S]. 北京: 中国标准出版社, 2014 National Standardization Administration Commission, State Quality Supervision, Inspection and Quarantine Administration. GB/T 31326-2014 Botanical beverage[S]. Beijing: China Standards Press, 2014.

[31] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 4789.2-2016食品安全国家标准 食品微生物学检验菌落总数测定[S]. 北京: 中国标准出版社, 2016 National Health and Family Planning Commission, State Food and Drug Administration. GB 4789.2-2016 National food safety standard Food microbiological analysis aerobic plate count[S]. Beijing: China Standards Press, 2016.

[32] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 4789.3-2016食品微生物学检验大肠菌群计数[S]. 北京: 中国标准出版社, 2016 National Health and Family Planning Commission, State Food and Drug Administration. GB 4789.3-2016 National food safety standard Food microbiological analysis Coliform microbiota count[S]. Beijing: China Standards Press, 2016.

[33] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 4789.15-2016食品微生物学检验霉菌和酵母计数[S]. 北京: 中国标准出版社, 2016 National Health and Family Planning Commission, State Food and Drug Administration. GB 4789.15-2016 National food safety standard Food microbiological analysis mold and yeast counts[S]. Beijing: China Standards Press, 2016.

[34] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 4789.10-2016食品微生物学检验金黄色葡萄球菌检验[S]. 北京: 中国标准出版社, 2016 National Health and Family Planning Commission, State Food and Drug Administration. GB 4789.10-2016 National food safety standard Food microbiological analysis Staphylococcus aureus test[S]. Beijing: China Standards Press, 2016.

[35] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 4789.4-2016食品微生物学检验沙门氏菌检验[S]. 北京: 中国标准出版社, 2016 National Health and Family Planning Commission, State Food and Drug Administration. GB 4789.4-2016 National food safety standard Food microbiological analysis Salmonella test[S]. Beijing: China Standards Press, 2016.

[36] 国家卫生和计划生育委员会, 国家食品药品监督管理总局. GB 4789.35-2016食品微生物学检验乳酸菌检验[S]. 北京: 中国标准出版社, 2016 National Health and Family Planning Commission, State Food and Drug Administration. GB 4789.35-2016 National food safety standard Food microbiological analysis Lactic acid bacteria test[S]. Beijing: China Standards Press, 2016.

[37] 苑园园. 超声波辅助酶解法制备豆粕ACE抑制肽的工艺优化[J]. 食品研究与开发,2022,43(17):134−140. [YUAN Y Y. Optimization of ACE inhibitory peptide preparation from soybean meal by ultrasound-assisted enzymolysis[J]. Food Research and Development,2022,43(17):134−140. doi: 10.12161/j.issn.1005-6521.2022.17.019 YUAN Y Y. Optimization of ACE inhibitory peptide preparation from soybean meal by ultrasound-assisted enzymolysis[J]. Food Research and Development, 2022, 43(17): 134-140. doi: 10.12161/j.issn.1005-6521.2022.17.019

[38] 马艳弘, 田丽敏, 孙小华, 等. 无花果酶解制汁工艺优化及抗氧化活性[J]. 食品研究与开发,2019,40(1):111−117. [MA Y H, TIAN L M, SUN X H, et al. Optimization of enzymatic hydrolysis for production of fig juice and antioxidant activity[J]. Food Research and Development,2019,40(1):111−117. MA Y H, TIAN L M, SUN X H, et al. Optimization of enzymatic hydrolysis for production of fig juice and antioxidant activity, 2019, 40(1): 111−117.

[39] 李治苇. 设施栽培冬枣成熟期品质特性的变化及食用酵素开发[D]. 银川: 宁夏大学, 2022 LI Z W. Changes in quality characteristics and product development of winter dates during the maturity period of the facility cultivation[D]. Yinchuan: Ningxia University, 2022.

[40] 向宇. 枸杞汁饮料加工工艺研究及工厂设计[D]. 武汉: 华中农业大学, 2017 XIANG Y. Study on processing technology and plant design of Chinese wolfberry juice beverage[D]. Wuhan: Huazhong Agricultural University, 2017.

[41] 杨培青. 蓝莓果渣酵素制备工艺的研究[D]. 沈阳: 沈阳农业大学, 2016 YANG P Q. Study on the preparation technology of blueberry pomace leaven[D]. Shenyang: Shenyang Agricultural University, 2016.

[42] 别蒙, 谢笔钧, 孙智达. 不同取代度水溶性羧甲基茯苓多糖的制备、结构表征及体外抑菌活性[J]. 食品科学,2020,41(12):67−76. [BIE M, XIE B J, SUN Z D. Preparation, structural characterization and in vitro antibacterial activity of water-soluble carboxymethyl pachymaran with different degrees of substitution[J]. Food Science,2020,41(12):67−76. doi: 10.7506/spkx1002-6630-20190603-015 BIE M, XIE B J, SUN Z D. Preparation, structural characterization and in vitro antibacterial activity of water-soluble carboxymethyl pachymaran with different degrees of substitution[J]. Food Science, 2020, 41(12): 67-76. doi: 10.7506/spkx1002-6630-20190603-015

[43] 孟然, 杨雅华, 李赵嘉, 等. 盐胁迫对不同时期盐地碱蓬组分含量的影响[J]. 食品工业科技,2021,42(20):44−50. [MENG R, YANG Y H, LI Z J, et al. Effect of salt stress on the component content of suaeda salsa in different periods[J]. Science and Technology of Food Industry,2021,42(20):44−50. doi: 10.13386/j.issn1002-0306.2021010072 MENG R, YANG Y H, LI Z J, et al. Effect of salt stress on the component content of suaeda salsa in different periods[J]. Science and Technology of Food Industry, 2021, 42(20): 44-50. doi: 10.13386/j.issn1002-0306.2021010072

[44] 周济源, 李海军, 张英华, 等. 纳他霉素发酵培养基的优化[J]. 食品工业,2022,43(7):45−48. [ZHOU J Y, LI H J, ZHANG Y H, et al. Optimization of natamycin fermentation medium[J]. The Food Industry,2022,43(7):45−48. ZHOU J Y, LI H J, ZHANG Y H, et al. Optimization of natamycin fermentation medium[J]. The Food Industry, 2022, 43(07): 45-48.

[45] 李尽哲, 张弛, 盛思佳, 等. 花脸香蘑山药菌质饮料的配方优化及其抗氧化活性[J]. 食品工业科技,2023,44(5):195−203. [LI J Z, ZHANG C, SHENG S J, et al. Optimization of formula and antioxidant activity of Lepista sordida and yam fungal substance beverage[J]. Science and Technology of Food Industry,2023,44(5):195−203. LI J Z, ZHANG C, SHENG S J, et al. Optimization of formula and antioxidant activity of Lepista sordida and yam fungal substance beverage[J]. Science and Technology of Food Industry, 2023, 44(5): 195−203.

[46] 郑聪, 李胜楠. 余甘子圣女果复合饮料发酵工艺及对运动耐力的影响[J]. 食品工业科技,2022,43(4):358−365. [ZHENG C, LI S N. Fermentation process of compound beverage with Phyllanthus emblica and cherry tomato and its effect on exercise endurance[J]. Science and Technology of Food Industry,2022,43(4):358−365. ZHENG C, LI S N. Fermentation process of compound beverage with Phyllanthus emblica and cherry tomato and its effect on exercise endurance[J]. Science and Technology of Food Industry, 2022, 43(4): 358-365.

[47] 贺莹. 新型小米南瓜香蕉混合发酵饮料的生产工艺[J]. 食品工业,2019,40(3):135−139. [HE Y. Research on the banana pumpkin millet fermented beverage production technology[J]. The Food Industry,2019,40(3):135−139. HE Y. Research on the banana pumpkin millet fermented beverage production technology[J]. The Food Industry, 2019, 40(3): 135-139.

[48] 郗恩光. 香蕉植株上乳酸菌的分离鉴定、特性研究及应用[D]. 海口: 海南大学, 2018 XI E G. The identification, basic research and application study of lactobacillus isolated from banana plants[D]. Haikou: Hainan University, 2018.

[49] 李慧, 韩卓, 叶玲, 等. 石榴芦荟柠檬复合发酵饮料的研制[J]. 农产品加工,2022(4):5−9. [LI H, HAN Z, YE L, et al. Preparation of pomegranate aloe lemon compound fermented beverage[J]. Farm Products Processing,2022(4):5−9. LI H, HAN Z, YE L, et al. Preparation of pomegranate aloe lemon compound fermented beverage[J]. Farm Products Processing, 2022(4): 5-9.

[50] 汪云阳, 单静博, 陈亚楠, 等. 枸杞发酵饮料的工艺优化及其风味物质分析[J]. 食品研究与开发,2020,41(18):40−47. [WANG Y Y, SHAN J B, CHEN Y N, et al. Optimization of fermentation technology and analysis of flavor substances of wolfberry[J]. Food Research and Development,2020,41(18):40−47. doi: 10.12161/j.issn.1005-6521.2020.18.007 WANG Y Y, SHAN J B, CHEN Y N, et al. Optimization of fermentation technology and analysis of flavor substances of wolfberry[J]. Food Research and Development, 2020, 41(18): 40-47. doi: 10.12161/j.issn.1005-6521.2020.18.007

[51] 赵芳娟. 天麻两菌耐高温驯化及栽培技术[D]. 汉中: 陕西理工大学, 2022 ZHAO F J. Domestication and cultivation techniques of high-temperature-resistant two strains of Gastrodia elata[D]. Hanzhong: Shanxi University of Technology, 2022.

[52] 张初署, 王明清, 于丽娜, 等. 单宁酶对花生衣提取液涩味脱除及滋味品质改善研究[J]. 花生学报,2021,50(2):50−56. [ZHANG C S, WANG M Q, YU L N, et al. Study on the removal of astringency and quality improvement of peanut testa extract by tannase[J]. Journal of Peanut Science,2021,50(2):50−56. doi: 10.14001/j.issn.1002-4093.2021.02.009 ZHANG C S, WANG M Q, YU L N, et al. Study on the removal of astringency and quality improvement of peanut testa extract by tannase[J]. Journal of Peanut Science, 2021, 50(2): 50-56. doi: 10.14001/j.issn.1002-4093.2021.02.009

[53] 郭强. 天麻淀粉结构及理化性质的研究[D]. 重庆: 西南大学, 2016 GUO Q. Study on the Structure and Physicochemical Properties of Rhizoma Gastrodiae Starch[D]. Chongqing: Southwest University, 2016.

[54] 于轩, 李才明, 顾正彪, 等. 淀粉分子结构与α-淀粉酶酶解性能的相关性[J]. 食品与发酵工业,2013,39(6):1−6. [YU X, LI C M, GU Z B, et al. Relationship of starch molecular structure and a-amylase hydrolysis performance[J]. Food and Fermentation Industries,2013,39(6):1−6. YU X, LI C M, GU Z B, et al. Relationship of starch molecular structure and a-amylase hydrolysis performance[J]. Food and Fermentation Industries, 2013, 39(6): 1-6.

[55] 谢莹. 小麦多孔淀粉的制备、结构性质及应用研究[D]. 合肥: 合肥工业大学, 2019 XIE Y. Preparation, structural properties and application of porous wheat starch[D]. Hefei: Hefei University of Technology, 2019.

[56] 赵敏, 王瑜, 李立郎, 等. 天麻酵素化过程中风味物质及抗氧化活性动态变化[J]. 食品与发酵工业,2021,47(22):92−98. [ZHAO M, WANG Y, LI L L, et al. Dynamic study on flavor components and antioxidant activity in the fermentation of Gastrodia elata[J]. Food and Fermentation Industries,2021,47(22):92−98. doi: 10.13995/j.cnki.11-1802/ts.027214 ZHAO M, WANG Y, LI L L, et al. Dynamic study on flavor components and antioxidant activity in the fermentation of Gastrodia elata[J]. Food and Fermentation Industries, 2021, 47(22): 92-98. doi: 10.13995/j.cnki.11-1802/ts.027214

[57] 朱苗, 田奇, 王锡念, 等. 天麻苦瓜绿茶复合饮料配方工艺优化[J]. 食品研究与开发,2021,42(4):112−116,142. [ZHU M, TIAN Q, WANG X N, et al. Formulation process optimization of compound beverage with Gastrodia elata, Momordica charantia L. and green tea[J]. Food Research and Development,2021,42(4):112−116,142. doi: 10.12161/j.issn.1005-6521.2021.04.019 ZHU M, TIAN Q, WANG X N, et al. Formulation process optimization of compound beverage with Gastrodia elata, Momordica charantia L. and Green Tea[J]. Food Research and Development, 2021, 42(4): 112-116, 142. doi: 10.12161/j.issn.1005-6521.2021.04.019

[58] 李刚凤, 杨娟, 朱苗, 等. 天麻藤茶红茶复合饮料工艺优化及其抗氧化活性研究[J]. 食品工业科技,2019,40(18):139−146. [LI G F, YANG J, ZHU M, et al. Process optimization and antioxidant activity of Gastrodia elata ampelopsis and black tea compound beverage[J]. Science and Technology of Food Industry,2019,40(18):139−146. doi: 10.13386/j.issn1002-0306.2019.18.023 LI G F, YANG J, ZHU M, et al. Process optimization and antioxidant activity of Gastrodia elata ampelopsis and black tea compound beverage[J]. Science and Technology of Food Industry, 2019, 40(18): 139-146. doi: 10.13386/j.issn1002-0306.2019.18.023

[59] 王超, 何梓钰, 査应洪, 等. 石斛汁乳酸发酵饮料的研制[J]. 食品与发酵工业,2014,40(11):265−268. [WANG C, HE Z Y, ZHA Y H, et al. Study on the lactic acid fermentation of Caulis dendrobii juice beverage[J]. Food and Fermentation Industries,2014,40(11):265−268. doi: 10.13995/j.cnki.11-1802/ts.201411046 WANG C, HE Z Y, ZHA Y H, et al. Study on the lactic acid fermentation of Caulis dendrobii juice beverage[J]. Food and Fermentation Industries, 2014, 40(11): 265-268. doi: 10.13995/j.cnki.11-1802/ts.201411046

[60] 吴映梅, 徐龙泉, 王瑶佳, 等. 薏苡仁乳酸菌发酵工艺优化及活性成分变化分析[J]. 食品研究与开发,2022,43(17):127−133. [WU Y M, XU L Q, WANG Y J, et al. Optimization of lactic acid bacteria fermentation of coix seed and analysis of its active components[J]. Food Research and Development,2022,43(17):127−133. doi: 10.12161/j.issn.1005-6521.2022.17.018 WU Y M, XU L Q, WANG Y J, et al. Optimization of lactic acid bacteria fermentation of coix seed and analysis of its active components[J]. Food Research and Development, 2022, 43(17): 127-133. doi: 10.12161/j.issn.1005-6521.2022.17.018

[61] 曹刚刚, 冀利峰, 徐方方, 等. 不同乳杆菌发酵对葛根的特征成分和抗氧化能力的影响研究[J]. 食品与发酵科技,2022,58(4):104−108. [CAO G G, JI L F, XU F F, et al. Effects of fermentation with different lactobacillus on characteristic components and antioxidant capacity of Pueraria root[J]. Food and Fermentation Sciences & Technology,2022,58(4):104−108. doi: 10.3969/j.issn.1674-506X.2022.04.017 CAO G G, JI L F, XU F F, et al. Effects of fermentation with different lactobacillus on characteristic components and antioxidant capacity of Pueraria root[J]. Food and Fermentation Sciences & Technology, 2022, 58(4): 104-108. doi: 10.3969/j.issn.1674-506X.2022.04.017

[62] FILANNINO P, CAGNO D R, GOBBETTI M. Metabolic and functional paths of lactic acid bacteria in plant foods: Get out of the labyrinth[J]. Current Opinion in Biotechnology,2018,49:64−72. doi: 10.1016/j.copbio.2017.07.016

[63] 刘梦洁, 尹清强, 常娟, 等. 植物乳杆菌和纤维素酶对玉米秸秆降解及糖化效果的影响[J]. 中国饲料,2020(23):34−39. [LIU M J, YIN Q Q, CHANG J, et al. Effects of Lactobacillus plantarum and cellulase on the degradation and saccharification of corn straw[J]. China Feed,2020(23):34−39. doi: 10.15906/j.cnki.cn11-2975/s.20202308 LIU M J, YIN Q Q, CHANG J, et al. Effects of Lactobacillus plantarum and cellulase on the degradation and saccharification of corn straw[J]. China Feed, 2020(23): 34-39. doi: 10.15906/j.cnki.cn11-2975/s.20202308

[64] 范俊华, 肖志剑, 张文. 植物乳杆菌发酵柚子汁复合饮料的研制[J]. 食品与发酵工业,2017,43(3):140−143. [FAN J H, XIAO Z J, ZHANG W. Development of Lactobacillus plantarum fermented grapefruit compound beverage[J]. Food and Fermentation Industries,2017,43(3):140−143. doi: 10.13995/j.cnki.11-1802/ts.201703025 FAN J H, XIAO Z J, ZHANG W. Development of Lactobacillus plantarum fermented grapefruit compound beverage[J]. Food and Fermentation Industries, 2017, 43(3): 140-143. doi: 10.13995/j.cnki.11-1802/ts.201703025

[65] 王彤, 刘慧燕, 潘琳, 等. 嗜酸乳杆菌发酵枣汁的非靶向代谢组学研究[J]. 中国酿造,2021,40(8):174−179. [WANG T, LIU H Y, PAN L, et al. Non-targeted metabolomics of fermented jujube juice by Lactobacillus acidophilus[J]. China Brewing,2021,40(8):174−179. doi: 10.11882/j.issn.0254-5071.2021.08.031 WANG T, LIU H Y, PAN L, et al. Non-targeted metabolomics of fermented jujube juice by Lactobacillus acidophilus[J]. China Brewing, 2021, 40(8): 174-179. doi: 10.11882/j.issn.0254-5071.2021.08.031

[66] 姚芳, 赵延胜, 王海蓝, 等. 银杏果酶解发酵前后风味成分的变化及主成分分析[J]. 现代食品科技,2021,37(6):251−265. [YAO F, ZHAO Y S, WANG H L, et al. Changes and principal component analysis of flavor components in ginkgo seed before and after enzymolysis-fermentation[J]. Modern Food Science and Technology,2021,37(6):251−265. doi: 10.13982/j.mfst.1673-9078.2021.6.0904 YAO F, ZHAO Y S, WANG H L, et al. Changes and principal component analysis of flavor components in ginkgo seed before and after enzymolysis-fermentation[J]. Modern Food Science and Technology, 2021, 37(6): 251-265. doi: 10.13982/j.mfst.1673-9078.2021.6.0904

下载:

下载:

下载:

下载: