Study on the Effect of Compound Improver on the Quality of Onion Paste Nang

-

摘要: 以洋葱浆馕为研究对象,分别探讨单硬脂酸甘油酯、大豆磷脂、α-淀粉酶和甘油4种改良剂对其感官评分和硬度的影响,以硬度为响应值,通过响应面分析法确定复配改良剂的最佳组合。结果表明,与对照组相比,单一改良剂均能改善洋葱浆馕的感官和硬度,延缓馕老化的速率。各因素添加量对洋葱浆馕硬度的影响主次顺序均为:α-淀粉酶>单甘酯>甘油>大豆磷脂。4种改良剂的最佳组合为:单甘酯添加量0.45%、大豆磷脂添加量0.62%、α-淀粉酶添加量0.06%、甘油添加量2.03%,对应的感官评分为90.92分,硬度为1190.72 g。通过验证实验,按此组合添加的洋葱浆馕感官评分为91.28分,硬度为1142.29 g。与对照组相比,感官评分增加了10.66分,硬度减小了621.61 g。与单一改良剂相比,复配改良剂在感官评分,硬度和延缓老化速率方面具有一定优势,能明显改善洋葱浆馕的品质,对延长洋葱浆馕货架期具有重要意义。Abstract: Taking onion paste Nang as the research object, effects of glycerol monasteries, soybean phospholipid, α-amylase and glycerol on sensory score and hardness were studied. Taking hardness as the response value, the best combination of compound modifiers was given in the response surface analysis. The results showed that opposed to the control group, a single modifier could improve the sensory and hardness of onion paste Nang and delay the aging rate of Nang. The primary and secondary order of the influence of the additional amount of each factor on the hardness of onion paste Nang was as follows: α-amylase>monoglyceride>glycerol>soybean phospholipid. The best combination of the four modifiers was 0.45% monoglyceride, 0.62% soybean phospholipid, 0.06% α-amylase and 2.03% glycerol, and the sensory score was 90.92 points, hardness was 1190.72 g. Through the validation test, the hardness of onion paste Nang added according to this combination was 1142.29 g and the sensory score was 91.28 points. Compared with the control group, the sensory score increased by 10.66 points and the hardness decreased by 621.61 g. Compared with the single modifier, the compound modifier has certain advantages in sensory score, hardness and delaying the aging rate. It can significantly improve the quality of onion paste Nang and is of great significance to prolong the shelf life of onion paste Nang.

-

Keywords:

- onion paste /

- Nang /

- improver /

- hardness /

- ageing

-

馕一般是以小麦面粉,玉米面粉或高粱面粉为原料,再加少许盐、水和酵母,发酵后将面团擀制饼状形馕胚,并用馕针在馕胚印上特殊花纹,撒上芝麻,贴在馕坑坑壁上烘烤而成的圆形烤饼,其具有色泽金黄、酥脆可口、不易变质等特点,人们有时会将羊肉、大葱、葡萄干、蜂蜜、黑胡椒、孜然等多种调料添加到馕的制作中去,所以其口味可达上百种[1]。目前,馕在贮藏过程中存在变硬、口感粗糙、无弹性等问题[2-3]。因此,如何延缓馕老化速率成为现阶段急需解决的问题[4]。馕在烘烤过程中,温度高于淀粉的糊化温度时,淀粉吸水就会发生糊化,导致β-淀粉结构受到破坏,会使淀粉分子之间的氢键断裂,断裂后淀粉和水通过氢键相连,实现了α-化(淀粉非结晶结构状态)。但馕在常温下贮藏时,由于温度差的原因,已经糊化α-淀粉开始自动进行排序,相邻的分子间氢键再次重新组合形成,重新形成了淀粉β-化(淀粉结晶结构状态),导致了洋葱浆馕的老化[5-8]。

国内外面制品加工业经常使用食品改良剂来改善面团操作性能及成品烘烤品质,目前常用的改良剂主要有氧化剂、还原剂、乳化剂及酶制剂等[9-14]。目前葡萄糖氧化酶[15]、单甘酯、脂肪酶[16]等食品改良剂对延缓面制品老化速率具有一定的作用。食品改良剂目前研究主要应用于豆制品[17]、糯米糕团[18]、面包[19-20]、蛋糕[21-22]中作为改良剂,但食品改良剂应用在馕中的研究报道罕见。

本实验研究了不同改良剂对馕质构特性和感官评价等品质的影响,以便对洋葱浆馕复配改良剂进行优化,得到最佳复配改良剂的配比,有效改善馕的品质,延缓馕老化速率,为延长洋葱浆馕货架期提供一定的参考依据。

1. 材料与方法

1.1 材料与仪器

天山牌小麦粉 新疆天山面粉有限责任公司;加碘精制盐 新疆盐湖制盐有限责任公司;纯正白糖 乌鲁木齐市同得利商贸有限公司;燕子即发酵母 乐斯福明光有限公司;菜籽油 中粮昌吉粮油工业有限公司;单硬脂肪酸甘油酯 广州嘉德乐生化科技有限公司;大豆磷脂 英博生物科技有限公司;α-淀粉酶 山东科隆特酶制剂有限公司;甘油 连云港新爱食品科技有限公司;白皮圆葱 市购;包装袋 市售。

PL 203型电子天平 梅特勒-托利多仪器上海有限公司;JSB15-05电子计重称 上海浦春计量仪器有限公司;LLJ-B12C8型打浆机 小熊电器股份有限公司;H20F立式双速和面机 广东力丰机制造有限公司;电馕坑 新疆想象环保科技公司;TA-XT Plus型物性测试仪 英国Stable Micro System公司。

1.2 实验方法

1.2.1 洋葱浆馕的生产流程及操作要点

洋葱浆馕的制作基本配方见表1。

表 1 洋葱浆馕基本配方(g)Table 1. Basic formula of onion paste Nang(g)成分 小麦粉 食盐 纯正白糖 酵母 植物油 洋葱浆 温水 洋葱浆馕 1000 18 30 5 24 270 300 馕的生产流程:原料→活化酵母→面团制作→醒发→面团分割→揉匀滚圆→醒发滚圆→成型(馕坯)→印花纹(打馕针)→粘洋葱碎→烘烤→冷却和包装。

操作要点:a.洋葱浆制备:将洋葱去皮,洗净,切片,用打浆机打浆,备用。b.原料:准确称取小麦面粉、食盐、白砂糖、酵母、植物油、洋葱浆、水和改良剂。c.活化酵母:将酵母加入30 ℃温水中活化。d.面团制作:按照基本配方将小麦粉、食盐、白砂糖、改良剂混合加入和面机中均匀搅拌。然后将活化好的酵母溶液、植物油、洋葱浆和水加入到和面机,并搅拌至面团揉出筋膜为止。e.醒发:待面团软硬适度,将其放在室温中(28~30 ℃),持续2 h。待其发酵至原体积2倍时取出。f.面团分割:面团醒发好后,取出排气,面团分割成自己需要的重量。g.揉匀滚圆:反复多次搓揉面团,排出发酵产生的气体、揉匀、揉透、至表面光滑。在揉面时讲究揉匀,这种馕吃起来劲道,也不会松散。h.醒发滚圆:将揉搓成的面团滚圆在面板上,并盖保鲜膜,放温暖处发酵30 min。i.成型:先用擀面杖将发酵面团擀压成圆饼状,然后用手抻成中间薄四周厚的形状,可以根据需求做不同形状馕坯。j.印花纹:用馕针在馕坯上打出均匀的花纹,戳花纹在入馕坑前,要戳透。k.粘洋葱碎:印花纹好的馕坯表面上粘一层洋葱碎。l.烘烤:先将电馕坑提前预热至200 ℃。然后成型的馕坯放入电馕坑中烤制10~15 min。m.冷却和包装:馕烘烤完毕,将其置于正常室温下1 h晾干,温度处于20~30 ℃左右时即可包装成品。

1.2.2 馕的感官评定

参照王彩虹等[23]方法,略有改动。将烘烤馕在室温放置1 h后进行感官品质评价。将洋葱浆馕实验样品随机编号,由10名(20~28岁,其中男生5名,女生5名)身体健康经培训后的食品专业学生评分小组,从色泽、风味、形态、口感、组织结构等5个方面进行感官评价,各个项目评分总和为100分。将每组得分结果取平均值,计算感官评分的最终结果。馕感官评分标准见表2。

表 2 馕感官评分标准Table 2. Sensory evaluation standards of Nang感官指标 评分标准 分数(分) 色泽 金黄色,焦色均匀,无焦糊现象 16~20 淡黄色,焦色较均匀,略有焦糊现象 11~15 黄棕色或乳白色,焦色较差,有明显焦糊现象 0~10 风味 浓郁的醒发和烘烤后的洋葱馕香味,酵母或配料味适中 17~20 淡淡的醒发和发酵后的洋葱馕香味,无异味 13~16 较淡的醒发和烘烤后的洋葱馕香味,酵母和配料味稍重 9~12 无洋葱馕特有的香味,酵母或配料产生的不良气味严重 0~8 形态 圆形规则,表面平整,厚薄均匀,花纹清晰,无明显鼓泡 15~20 圆形规则,表面较平整,厚薄均匀,花纹清晰,有少量的鼓泡 9~14 圆形不规则,表面较平整,厚度不均匀,花纹不清晰,有较大的鼓泡 0~8 口感 软硬适中,不粘牙,略有嚼劲 20~25 硬度偏硬或偏软,较粘牙,较有嚼劲 14~19 干硬,粘牙,不易下咽,嚼劲较大 0~13 组织结构 质地细腻,气孔均匀,柔软有弹性 11~15 质地细腻,气孔较均匀,弹性较差 6~10 质地不细腻,气孔不均匀,无弹性 0~5 1.2.3 洋葱浆馕质构的测定

参照邹淑萍等[24]方法,稍做改动。将烤制好的馕室温冷却1 h,取大小为2 cm的馕方块(分馕心和馕边,这与馕特殊结构有关,边缘远高于中间3倍厚度的称为馕边,中间薄的部分称为馕心),重复3次,用质构仪进行测试。测定硬度、弹性、内聚性和咀嚼性。TPA参数测试条件为:采用P/5平底柱型探头,测前速率2.0 mm/s,测试速率5.0 m/s,测后速率5.0 mm/s,触发力10 g,压缩比65%,两次压缩时间间隔5 s,返回距离30 mm,返回速度10 mm/s。

1.2.4 复合改良剂配比优化

含有高淀粉和蛋白质的馕很容易被氧化,从而使馕变质变硬,为了防止馕的变质变硬问题,选取单硬脂酸甘油酯、大豆磷脂、α-淀粉酶和甘油4种改良剂进行单因素实验,确定最佳添加量。然后在单因素实验结果基础上,进行响应面试验确定复配改良剂的最佳组合。

1.2.4.1 单因素实验

以面粉100 g为基准,以洋葱浆馕的感官评分、硬度、弹性、内聚性和咀嚼性为评价指标,研究单硬脂酸甘油酯添加量0%、0.3%、0.4%、0.5%、0.6%、0.7% (不添加其他三种改良剂,下同),大豆磷脂添加量0%、0.3%、0.4%、0.5%、0.6%、0.7%,α-淀粉酶添加量0%、0.04%、0.05%、0.06%、0.07%、0.08%,甘油添加量0%、0.5%、1.0%、1.5%、2.0%、2.5%对洋葱浆馕品质的影响。

1.2.4.2 响应面试验

根据单因素实验结果,利用Box-Behnken原理,设计响应面试验,从而确定最佳复合改良剂的配方。响应面试验因素和水平见表3。

表 3 响应面试验因素与水平Table 3. Factors and levels of response surface test水平 A 单甘酯

添加量(%)B 大豆磷脂

添加量(%)C α-淀粉酶

添加量(%)D 甘油

添加量(%)1 0.4 0.5 0.05 1.5 2 0.5 0.6 0.06 2.0 3 0.6 0.7 0.07 2.5 将冷却好的洋葱浆馕放置于室温冷却1 h,测定样品的感官评分和质构特性品质指标。每个样品进行3次平行测定,计算平均值。采用SPSS软件,分析洋葱浆馕感官评分与质构特性的相关性。考虑到质构特性的客观性,以硬度作为响应值,利用Design-Expert 10.0.4软件进行数据分析,并确定复配改良剂的最佳组合。

1.3 数据处理

采用 SPSS 20.0软件进行统计分析,数据以平均值±标准误差(X±SD)来表示,P<0.05表示差异具有统计学意义。采用Origin 2019b 软件进行绘图,采用Design-Expert.V8.0.6.1进行响应面分析。

2. 结果与分析

2.1 不同改良剂对洋葱浆馕品质的影响

2.1.1 单硬脂酸甘油酯添加量对洋葱浆馕品质的影响

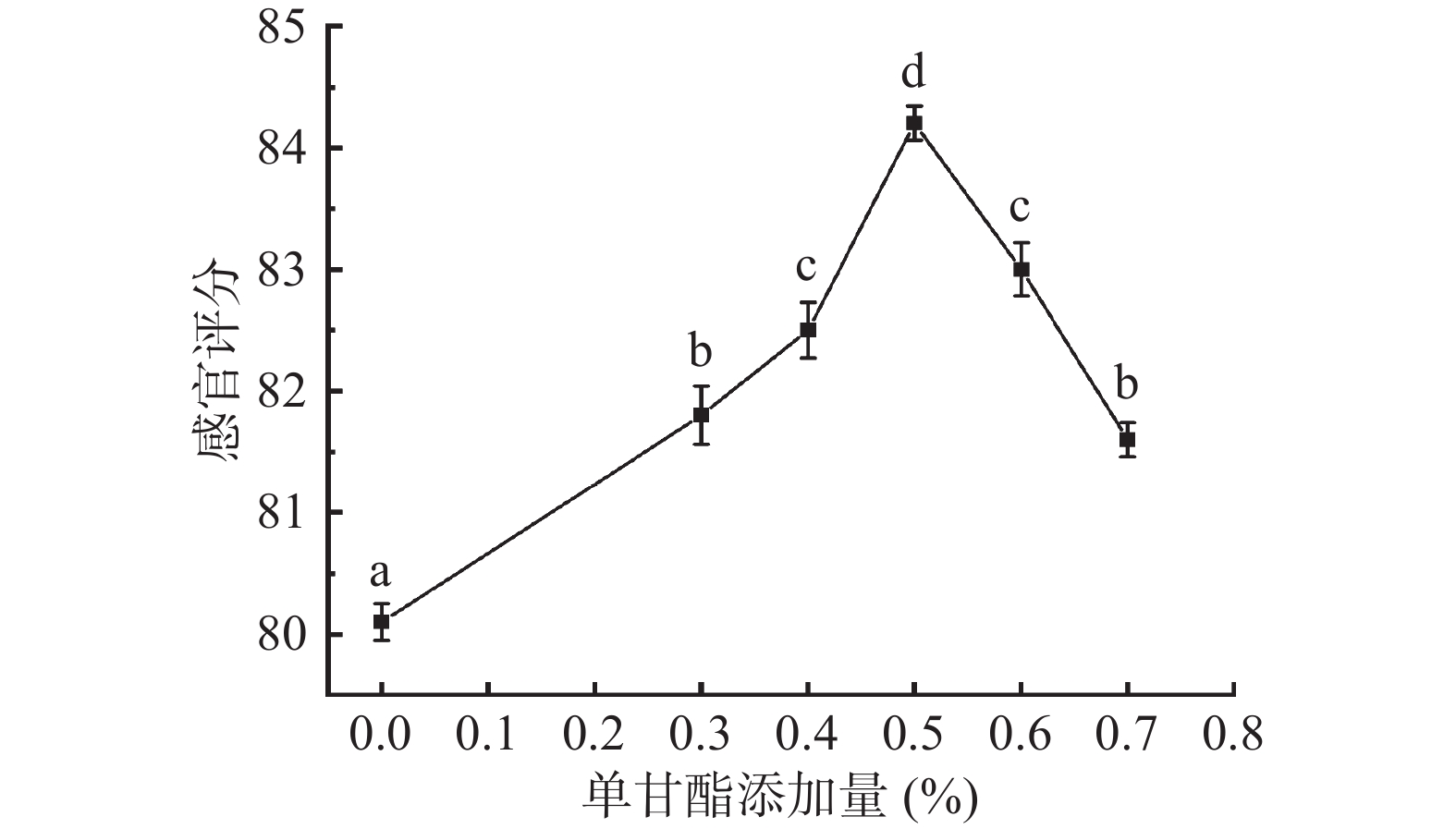

单硬脂酸甘油酯是一种非离子型的表面活性剂,也简称单甘酯[25],单甘酯作为面制品的组织软化剂,对面制品起到抗氧化作用[26]。单甘酯添加量对洋葱浆馕质构特性的影响见表4、表5,单甘酯添加量对洋葱浆馕感官的影响见图1。

表 4 单甘酯添加量对洋葱浆馕馕边质构特性的影响Table 4. Effect of monoglyceride addition on texture properties of Nang edge of onion pulp单甘酯添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1768.89±28.45e 1.26±0.59b 0.48±0.02a 1104.01±69.99d 0.3 1570.07±55.73d 0.88±0.04ab 0.53±0.01b 903.81±65.68c 0.4 1396.28±77.97c 0.83±0.01ab 0.58±0.01c 767.32±34.73b 0.5 1182.99±77.14b 0.80±0.00a 0.67±0.05d 638.57±22.74a 0.6 1069.27±62.37a 0.76±0.01a 0.57±0.01bc 589.33±62.55a 0.7 1005.31±39.50a 0.74±0.00a 0.54±0.01bc 618.77±71.78a 注:不同字母表示同列中数值间显著性差异(P<0.05);表5~表11同。 表 5 单甘酯添加量对洋葱浆馕馕心质构特性的影响Table 5. Effect of monoglyceride addition on textural properties of Nang core of onion paste单甘酯添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1929.22±71.82e 1.01±0.20b 0.52±0.02a 1058.75±61.22d 0.3 1644.00±130.42d 0.89±0.02ab 0.58±0.01b 962.96±1471c 0.4 1443.11±44.16c 0.86±0.01ab 0.62±0.01c 846.1±128.51b 0.5 1199.79±63.13b 0.83±0.01a 0.67±0.02d 714.15±35.48a 0.6 1070.49±48.12b 0.80±0.01a 0.61±0.03bc 691.88±18.93a 0.7 903.17±86.80a 0.76±0.03a 0.58±0.01b 707.92±79.90a 由表4、表5可知,随着单甘酯添加量的增加,洋葱浆馕馕边、馕心的硬度、弹性呈一直降低趋势,内聚性呈先升高后降低趋势,咀嚼性呈先降低后升高趋势。这是因为添加单甘酯后,单硬脂酸甘油酯的疏水基团进入螺旋结构内与之络合,形成螺旋复合体,不但使得淀粉中的直链淀粉不易发生重结晶,还能使淀粉的吸水溶胀能力减小,使更多的水分向蛋白转移,从而防止淀粉的老化[26-28]。单甘酯添加量为0%~0.5%时,馕心和馕边的硬度,内聚性和咀嚼性存在显著性差异(P<0.05);当单甘酯添加量大于0.5%后,质构特性基本无显著变化(P>0.05)。

由图1可知,单甘酯的添加量为0%~0.7%时,感官评分随着单甘酯添加量增大而先增大后减小,添加量为0.5%时感官评分最高。单甘酯添加量大于0.5%时,洋葱浆馕的感官有所下降,可见单甘酯添加量过大会对洋葱浆馕的总体品质有不良影响。结合洋葱浆馕的馕边和馕心的感官评分和质构特性,得出的单甘酯添加量0.5%为最佳。

2.1.2 大豆磷脂添加量对洋葱浆馕品质的影响

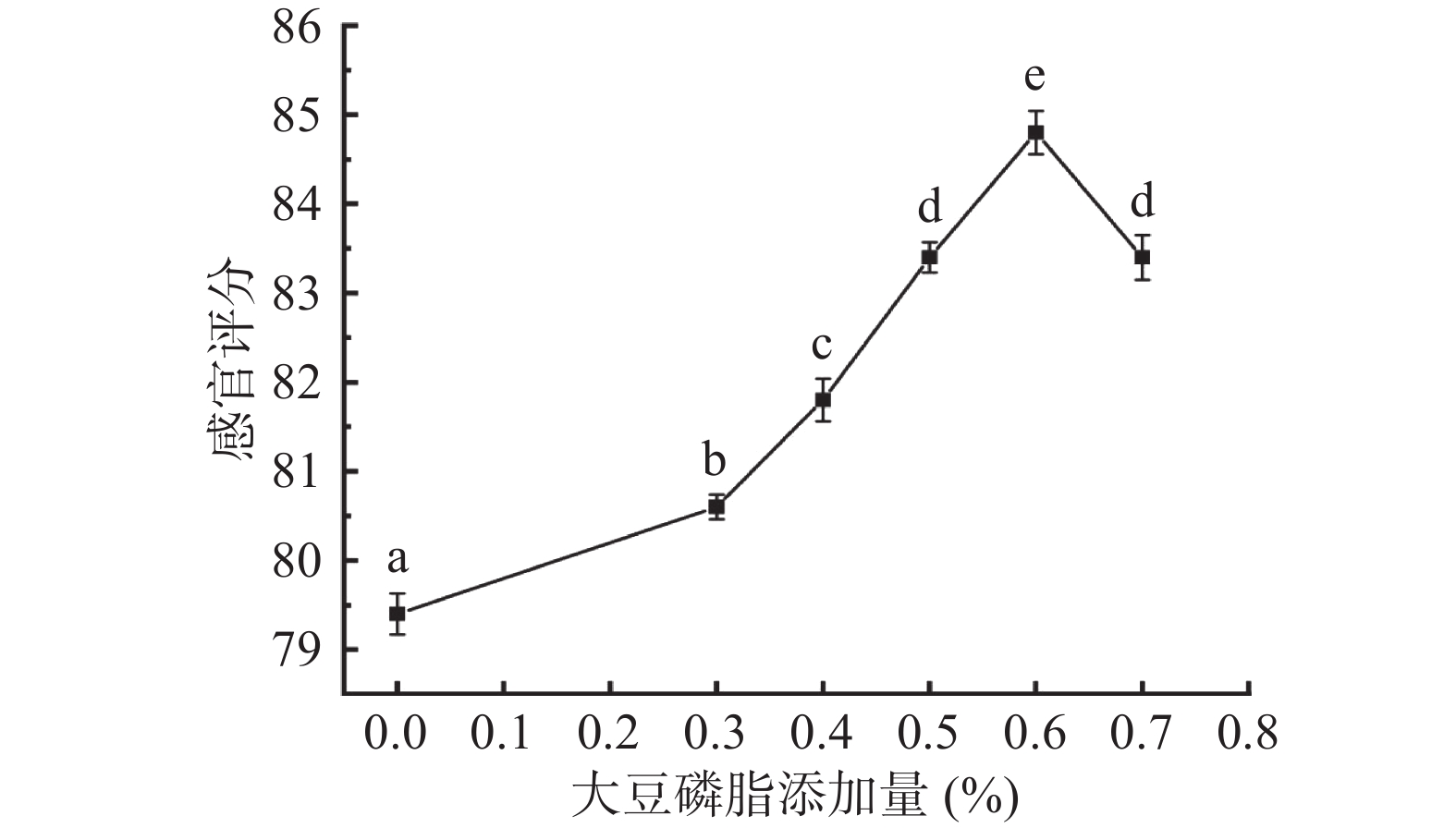

大豆磷脂是一种既有亲水性又有疏水性的两性表面活性剂,对原料搅拌混合的均匀和稳定性有影响[29]。大豆磷脂添加量对洋葱浆馕质构特性的影响见表6、表7,大豆磷脂添加量对洋葱浆馕感官的影响见图2。

表 6 大豆磷脂添加量对洋葱浆馕馕边质构特性的影响Table 6. Effect of soybean lecithin addition on texture properties of Nang edge of onion paste大豆磷脂添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1780.44±43.02d 1.01±0.04e 0.52±0.02a 478.07±17.97a 0.3 1666.09±26.79d 0.90±0.02d 0.56±0.01c 530.17±27.17b 0.4 1469.89±6235c 0.85±0.01bc 0.58±0.01d 582.29±14.45c 0.5 1326.54±43.21b 0.77±0.01a 0.54±0.01b 471.39±10.16a 0.6 1127.42±91.94a 0.83±0.01b 0.61±0.01e 571.43±12.15c 0.7 1206.99±109.72a 0.88±0.01cd 0.57±0.01cd 500.69±8.63a 表 7 大豆磷脂添加量对洋葱浆馕馕心质构特性的影响Table 7. Effect of soybean lecithin addition on texture properties of Nang core of onion paste大豆磷脂添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1974.16±43.93e 1.02±0.20b 0.49±0.01a 590.67±65.96a 0.3 1757.96±11.11d 0.88±0.02ab 0.54±0.01b 714.89±15.19bc 0.4 1646.51±81.50c 0.84±0.01a 0.62±0.01d 773.75±27.22c 0.5 1405.20±70.30b 0.79±0.01a 0.58±0.01c 653.94±14.50ab 0.6 1213.18±25.64a 0.85±0.01a 0.63±0.01d 744.38±10.95c 0.7 1303.39±53.50a 0.89±0.00ab 0.57±0.01c 608.4±765.09a 由表6、表7可知,随着大豆磷脂添加量的增加,洋葱浆馕馕边、馕心的硬度先降低后增大,这是因为大豆磷脂会有助于酵母的生长,提高发酵能力,提高面团持气性,起到软化面团、降低硬度的效果[30]。弹性先降低后增大,是因为大豆磷脂的疏水基团渗透到面筋蛋白的空间结构中,生成更稳定的络合物,导致弹性的变化[31]。而内聚性和咀嚼性呈现出相同的趋势,但差异不显著。大豆磷脂添加量为0%~0.6%时,馕心和馕边的硬度存在显著性差异(P<0.05),弹性和咀嚼性基本无差异。当大豆磷脂添加量为0.6%时,洋葱浆馕的硬度最低,内聚性最高。

由图2可知,大豆磷脂的添加量为0.3%~0.7%时,感官评分随着大豆磷脂添加量增大而先增大后减小,添加量为0.6%时感官评分最高。大豆磷脂添加量大于0.6%时,洋葱浆馕的感官有所下降。结合洋葱浆馕的馕边和馕心的感官评分和质构特性,得出的大豆磷脂添加量0.6%为最佳。

2.1.3 α-淀粉酶添加量对洋葱浆馕品质的影响

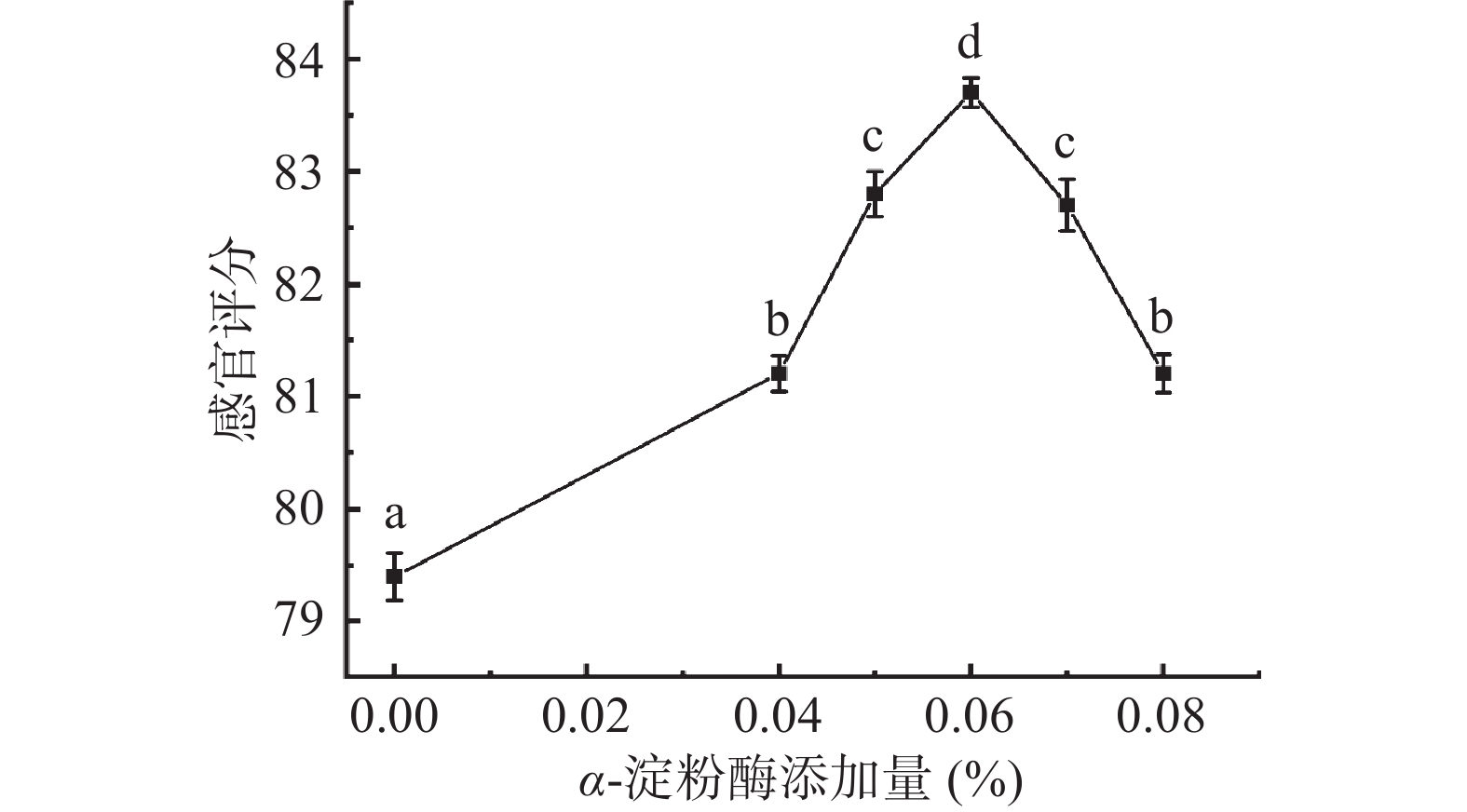

α-淀粉酶是一种比较广泛使用的酶制剂。α-淀粉酶添加量对洋葱浆馕质构特性的影响见表8、表9,α-淀粉酶添加量对洋葱浆馕感官的影响见图3。

表 8 α-淀粉酶添加量对洋葱浆馕馕边质构特性的影响Table 8. Effect of a-amylase addition on texture characteristics of Nang edge of onion pastea-淀粉酶添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1470.49±35.76d 0.76±0.01b 0.47±0.01a 625.88±49.54b 0.04 1346.80±42.23c 0.72±0.02a 0.50±0.01b 535.25±25.21a 0.05 1196.18±42.56b 0.82±0.01c 0.53±0.01c 478.86±15.96a 0.06 1025.73±76.53a 0.87±0.00d 0.58±0.01d 517.17±14.15a 0.07 1234.03±31.40b 0.81±0.01c 0.61±0.02e 502.18±59.91a 0.08 1331.85±30.42c 0.75±0.05ab 0.54±0.01c 482.14±26.65a 表 9 α-淀粉酶添加量对洋葱浆馕馕心质构特性的影响Table 9. Effect of a-amylase addition on texture characteristics of Nang core of onion pastea-淀粉酶添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1672.49±52.14d 0.80±0.03b 0.54±0.01a 775.57±80.51c 0.04 1519.08±24.89c 0.76±0.01a 0.56±0.04a 516.19±13.78a 0.05 1391.82±52.80b 0.85±0.01c 0.63±0.02b 558.21±26.37a 0.06 1267.42±37.32a 0.90±0.02d 0.67±0.01c 673.61±58.61b 0.07 1379.72±47.18b 0.85±0.01c 0.63±0.01a 583.25±41.06ab 0.08 1443.83±30.09b 0.82±0.02bc 0.58±0.01a 520.27±69.01a 由表8、表9可知,随着α-淀粉酶添加量的增加,馕的质构特性显著性改善(P<0.05),洋葱浆馕馕边、馕心的硬度先降低后增大,弹性先降低后增大又降低,内聚性先增大后降低,咀嚼性先降低后增大最后又降低。这是因为α-淀粉酶能把淀粉分子水解成低分子的糊精和可溶性淀粉,低分子的糊精进一步影响淀粉与蛋白质网络结构间的相互作用,使馕老化速率缓慢,保持馕的松软[32-34]。但α-淀粉酶用量过多时会使洋葱浆馕发粘,不利于延缓馕的老化,因此应适当控制添加量。α-淀粉酶添加量为0%~0.06%时,馕心和馕边的硬度存在显著性差异(P<0.05)。当添加量0.06%时,硬度最低,弹性最高。当α-淀粉酶添加量大于0.06%后,呈现硬度增大,弹性减小的趋势。说明说明α-淀粉酶添加量0.06%时为最佳添加量。

由图3可知,α-淀粉酶的添加量为0%~0.08%时,感官评分随着α-淀粉酶添加量增大而先增大后减小,添加量为0.06%时感官评分最高。故选择α-淀粉酶添加量0.06%进行后续试验。结合洋葱浆馕的馕边和馕心的感官评分和质构特性,得出的α-淀粉酶添加量0.06%为最佳。

2.1.4 甘油(丙三醇)添加量对洋葱浆馕品质的影响

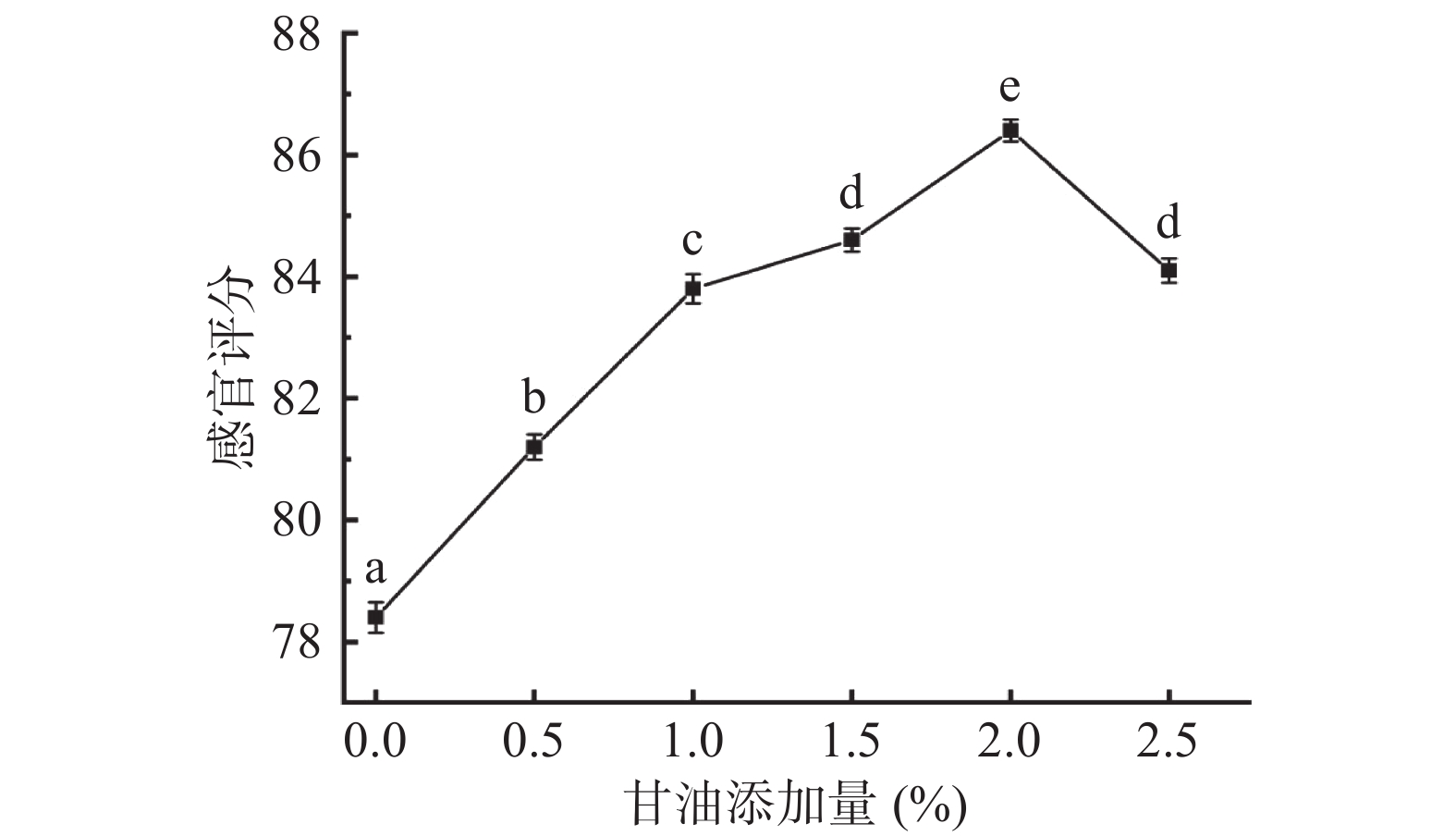

甘油是一种非离子型的表面活性剂,也叫丙三醇。甘油添加量对洋葱浆馕质构特性的影响见表10、表11,甘油添加量对洋葱浆馕感官的影响见图4。

表 10 甘油添加量对洋葱浆馕馕心质构特性的影响Table 10. Effect of glycerol addition on texture characteristics of Nang edge of onion paste甘油添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1572.45±58.05e 0.97±0.08c 0.63±0.02c 1156.76±64.28d 0.5 1384.52±52.63d 0.80±0.02a 0.55±0.01a 972.34±33.29c 1.0 1212.75±75.21c 0.84±0.01a 0.58±0.01b 866.59±39.47b 1.5 1015.42±72.83b 0.85±0.01ab 0.62±0.01c 779.97±17.34ab 2.0 940.09±16.05a 0.91±0.01b 0.67±0.01d 858.96±57.44b 2.5 1142.62±42.30b 0.86±0.01ab 0.62±0.02c 706.57±72.58a 表 11 甘油添加量对洋葱浆馕馕心质构特性的影响Table 11. Effect of glycerol addition on texture characteristics of Nang core of onion paste甘油添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1752.10±27.03e 1.00±0.11c 0.68±0.01d 1099.18±85.98d 0.5 1470.58±72.40d 0.84±0.01a 0.56±0.01a 972.19±55.72c 1.0 1315.57±71.31c 0.87±0.01ab 0.58±0.01b 861.59±52.31b 1.5 1207.90±58.53b 0.88±0.01ab 0.62±0.01c 723.25±27.03a 2.0 1082.24±62.74a 0.94±0.02bc 0.67±0.01d 828.19±81.17b 2.5 1239.59±53.13b 0.87±0.01ab 0.62±0.01c 706.04±16.72a 由表10、表11可知,随着甘油添加量的增加,馕的质构特性显著性改善(P<0.05),洋葱浆馕馕边、馕心的硬度先降低后增大,弹性和内聚性先增大后减小,咀嚼性先减小后增大又减小。甘油添加量为0.5%~2.5%时,馕心和馕边的硬度、咀嚼性存在显著性差异(P<0.05);弹性和内聚性先增大后降低的趋势,但是无显著性差异(P>0.05);内聚性一直增大的趋势,但始终会小于未添加;当甘油添加量为2.0%时,硬度最低,弹性最大。当甘油添加量大于2.0%后,质构特性无明显变化。

由图4可知,甘油的添加量为0.5%~2.5%时,感官评分随着甘油添加量增大而先增大后减小,添加量为2.0%时感官评分最高。适量的甘油使有效地改善洋葱浆馕的感官品质,但是通过感官评价发现过量的甘油导致洋葱浆馕口味发苦。随着添加量的增加,苦味越来越重,从而导致感官评分下降[35-37]。此外,随着添加量过多时,馕的内部组织结构膨松度变小,从而导致弹性变差,且内聚性也降低。结合洋葱浆馕的馕边和馕心的感官评分和质构特性,得出的甘油添加量2.0%为最佳。

2.2 响应面优化

2.2.1 响应面试验设计及结果

由单因素实验的基础可知,4种改良剂对洋葱浆馕馕边、馕心质构特性效果一致的,故选择洋葱浆馕馕边进行后续试验。因此,确定单甘酯、大豆磷脂、α-淀粉酶、甘油添加量为自变量4个因素。在此基础上,以感官评分和质构特性为响应值,进行4因素3水平的响应面试验,试验结果见表12。

表 12 响应面试验设计与结果Table 12. Design and results of response surface test试验号 A B C D 感官评分 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 1 1 −1 0 0 83.29 1286.87 0.85 0.59 779.63 2 0 0 0 0 91.23 1191.11 1.18 0.68 529.63 3 −1 0 1 0 86.13 1246.47 0.94 0.52 749.63 4 0 1 1 0 84.49 1267.47 0.88 0.56 713.12 5 0 −1 0 −1 80.73 1318.51 0.65 0.71 689.92 6 0 −1 1 0 80.43 1324.67 0.74 0.71 902.79 7 −1 0 −1 0 78.33 1368.27 0.67 0.76 976.99 8 0 −1 0 1 81.79 1317.87 0.69 0.7 672.14 9 0 0 0 0 90.49 1198.87 1.14 0.48 546.08 10 −1 0 0 1 84.93 1254.87 0.92 0.54 683.66 11 0 0 0 0 90.19 1204.47 1.09 0.48 575.83 12 1 1 0 0 82.23 1301.07 0.8 0.64 1019.13 13 −1 1 0 0 87.33 1242.27 0.97 0.51 632.55 14 −1 −1 0 0 84.33 1271.67 0.86 0.57 738.31 15 0 0 −1 −1 75.23 1444.11 0.55 0.81 1071.94 16 0 0 −1 1 75.39 1432.51 0.61 0.8 1054.7 17 1 0 −1 0 75.63 1422.87 0.63 0.79 1035.79 18 −1 0 0 −1 83.73 1275.87 0.91 0.59 849.98 19 0 −1 −1 0 77.73 1408.31 0.66 0.77 998.45 20 0 0 0 0 89.73 1233.87 1.08 0.51 608.1 21 0 0 1 −1 78.63 1351.47 0.88 0.73 855.46 22 1 0 0 −1 80.13 1326.27 0.62 0.71 830.23 23 0 1 0 −1 79.23 1327.51 0.71 0.72 942.86 24 1 0 1 0 82.53 1290.71 0.71 0.62 801.02 25 0 1 0 1 82.99 1290.71 0.84 0.59 794.72 26 0 0 1 1 81.93 1311.71 0.83 0.67 835.34 27 0 1 −1 0 75.69 1411.87 0.74 0.77 1011.78 28 0 0 0 0 89.89 1205.31 0.9 0.5 598.16 29 1 0 0 1 81.79 1312.67 0.71 0.68 859.26 计算洋葱浆馕感官评分和质构特性之间相关系数,从表13可以看出,感官评分与硬度、内聚性、咀嚼性呈极显著的负相关(P<0.01);而与弹性呈正相关(P<0.01)。其中硬度相关系数绝对值最大,说明硬度的大小可以较好地反映感官评分的高低,如果硬度越小,则感官评分越高。

表 13 感官评分和质构特性间的相关系数Table 13. Correlation coefficient between sensory score and texture characteristics品质指标 感官评分 硬度 弹性 内聚性 咀嚼性 感官评分 1.000 硬度 −0.976** 1.000 弹性 0.895** −0.859** 1.000 内聚性 −0.886** 0.896** −0.784** 1.000 咀嚼性 −0.911** 0.902** −0.786** 0.786** 1.000 注: **表示差异极显著(P<0.01)。 因此,选择硬度为响应值,使用软件 Design-Expert.V8.0.6.1分析得到4种改良剂对硬度的二次多元回归拟合预测模型方程:Y=1206.73+23.42A−7.25B−57.95C−10.28D+10.90AB−2.59AC+1.85AD−15.19BC−9.04BD−7.04CD+21.35A2+42.46B2+106.42C2+66.87D2

由表14 可知,建立的硬度回归模型中的F=71.26,P<0.0001,达到极显著水平,得出R2=0.9862,说明拟合程度良好,试验误差较小。模型的校正决定系数R2Adj=0.9723,表明该模型是可行的。失拟项P=0.9168>0.05,表示失拟项差异不显著,说明该回归方程能较好的拟合真实的响应面值。模型的一次项 A、C、D(P<0.01)影响极显著,B(P>0.05)影响不显著;二次项 A2、B2、C2、D2(P<0.01)影响均极显著;交互项BC(P<0.05)影响显著,AB、AC、AD、BD、CD(P>0.05)影响均不显著;由F值可知4因素添加量对硬度影响的主次顺序为 α-淀粉酶>单甘酯>甘油>大豆磷脂。

表 14 响应面回归模型方差分析表(硬度)Table 14. Analysis of variance of response surface regression model (Hardness)方差来源 平方和 自由度 均方 F值 P 显著性 模型 1.41E+05 14 10065.2 71.26 < 0.0001 ** A 6581.96 1 6581.96 46.6 < 0.0001 ** B 630.75 1 630.75 4.47 0.053 C 40303.07 1 40303.07 285.33 < 0.0001 ** D 1268.96 1 1268.96 8.98 0.0096 ** AB 475.24 1 475.24 3.36 0.0880 AC 26.83 1 26.83 0.19 0.6696 AD 13.69 1 13.69 0.097 0.7601 BC 922.94 1 922.94 6.53 0.0228 * BD 326.89 1 326.89 2.31 0.1505 CD 198.25 1 198.25 1.4 0.2559 A2 2955.86 1 2955.86 20.93 0.0004 ** B2 11695.27 1 11695.27 82.8 < 0.0001 ** C2 73456.72 1 73456.72 520.04 < 0.0001 ** D2 29006.69 1 29006.69 205.35 < 0.0001 ** 残差 1977.53 14 141.25 失拟项 928.06 10 92.81 0.35 0.9168 纯误差 1049.47 4 262.37 总和 1.43E+05 28 R2=0.9862 R2Adj=0.9723 C.V.%=0.91 注: **表示差异极显著(P<0.01),*表示差异显著(P<0.05)。 2.2.2 复配改良剂最佳组合的确定

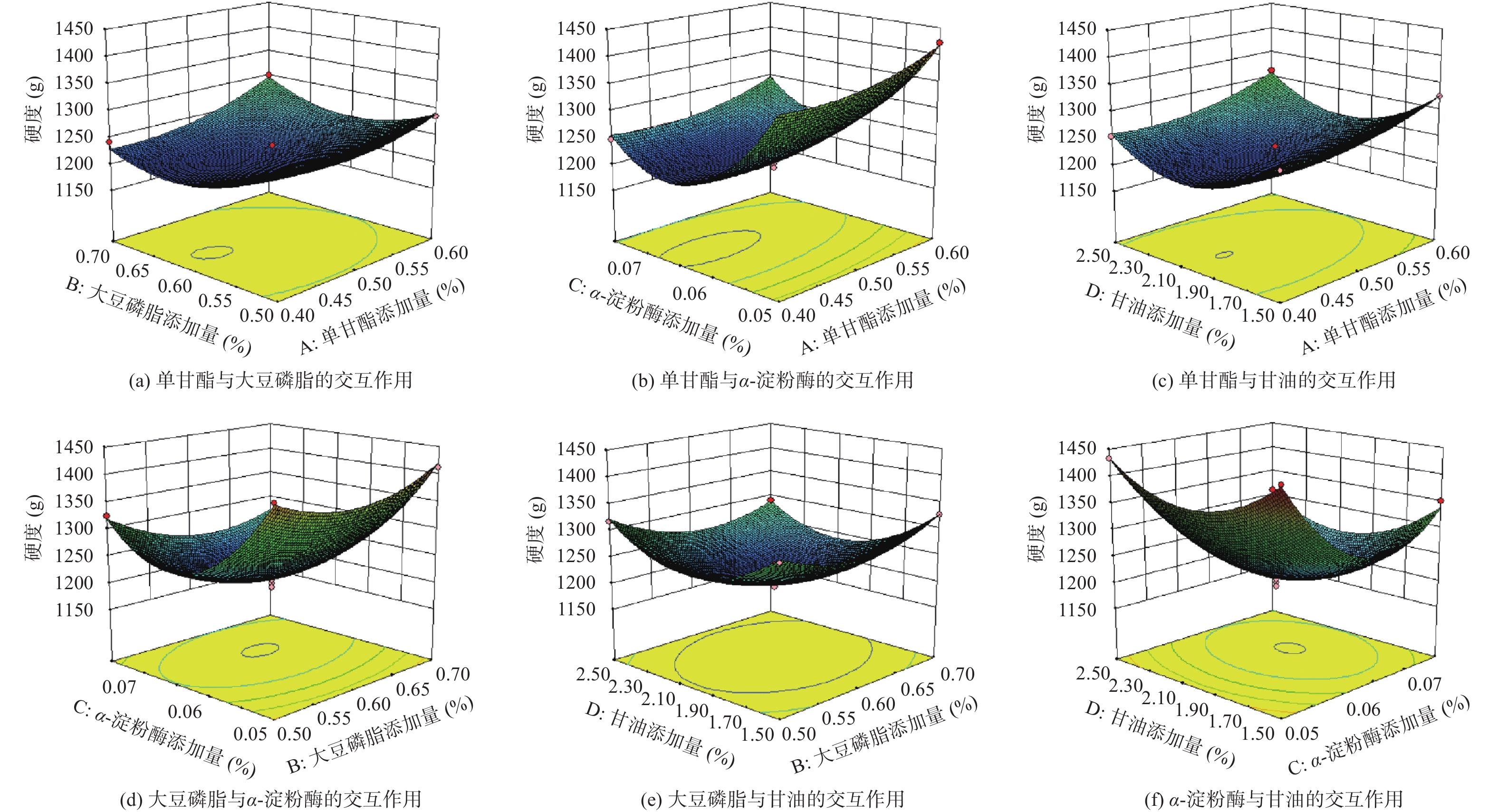

各因素交互作用对洋葱浆馕硬度影响的响应面图见图5。

等高线图的形状来可以判断各组因素间交互效应的强弱[38-39]。由图5可知,各因素交互作用对洋葱浆馕硬度影响的响应面图均为一个向上的曲面,响应面曲线较陡,说明随着各因素取值的减小,各因素洋葱浆馕硬度的影响先减小后增大,且各因素取值较小时影响较大。大豆磷脂添加量与α-淀粉酶添加量的响应面最陡,说明大豆磷脂添加量与α-淀粉酶添加量的交互作用最明显。而AB、BD、CD、AC、AD交互作用等高线图的椭圆形扁平程度较小,尤其是AC和AD交互作用等高线图没有呈现明显的椭圆形,而是接近于圆形,说明其交互作用不明显,这与表14的分析结果一致。

根据响应面分析,可得复配改良剂的最佳组合:单甘酯添加量0.45%、大豆磷脂添加量0.62%、α-淀粉酶添加量0.06%、甘油添加量2.03%,此时洋葱浆馕的感官评分为90.92分,硬度为1190.72 g。

2.3 验证实验

为了进一步检验响应面方法优化复配改良剂的可靠性,使用改进条件开展具体验证操作。

贮藏在4℃,6 d后的优化前后洋葱浆馕的品质指标见表15。

表 15 优化前后洋葱浆馕的品质指标Table 15. Quality index of onion paste Nang before and after optimization贮藏时间(d) 样品 感官评分 硬度(g) 0 优化前洋葱浆馕馕边 80.62±0.19 1763.90±68.2 优化后洋葱浆馕馕边 91.28±0.35 1142.29±87.53 6 优化前洋葱浆馕馕边 72.03±0.39 8201.52±169.3 优化后洋葱浆馕馕边 85.52±0.21 3613.94±52.67 通过验证实验可知,未加复配改良剂洋葱浆馕的感官评分为80.62分,硬度为1763.90 g;按复配改良剂的最佳组合的洋葱浆馕感官评分为91.28分,硬度为1142.29 g,与预测值接近,与对照组相比,感官评分增加了10.66分,硬度减小了621.61 g。表明响应面法优化的复配改良剂最佳组合准确可靠。贮藏在4 ℃,6 d后的未加复配改良剂洋葱浆馕的感官评分为72.03分,硬度为8201.52 g;添加复配改良剂洋葱浆馕的感官评分为85.52分,硬度为3613.94 g。添加复配改良剂的洋葱浆馕的感官评分和硬度变化幅度比未添加复配改良剂的小。由此可得,添加一定量的复配改良剂能够有效地改善洋葱浆馕的感官评分和质构品质指标。实验验证值接近模型的预测值,表明模型较好地预测了洋葱浆馕的复配改良剂最佳添加量组合。

3. 结论

本实验首先通过单因素实验确定单甘酯添加量、大豆磷脂添加量、α-淀粉酶添加量和甘油添加量的最佳添加量。然后将4种改良剂复配后进行响应面试验,测定洋葱浆馕品质的相关指标。结果表明,洋葱浆馕感官评分与硬度、内聚性、咀嚼性呈极显著的负相关(P<0.01),而与弹性呈正相关(P<0.01)。选择与感官评分相关性最强的硬度为响应值,确定复配改良剂的最佳组合:单甘酯添加量0.45%、大豆磷脂添加量0.62%、α-淀粉酶添加量0.06%、甘油添加量2.03%,对应的感官评分为90.92分,硬度为1190.72 g。通过验证试验,按此组合添加的洋葱浆馕感官评分为91.28分,硬度为1142.29 g。与对照组相比,感官评分增加了10.66分,硬度减小了621.61 g。在贮藏期内,添加复配改良剂的洋葱浆馕硬度低于未加复配改良剂的硬度,且硬度变化幅度也较小。说明复配改良剂能够明显改善洋葱浆馕的感官评价,质构品质和老化速率,对延长洋葱浆馕货架期具有重要意义。

-

表 1 洋葱浆馕基本配方(g)

Table 1 Basic formula of onion paste Nang(g)

成分 小麦粉 食盐 纯正白糖 酵母 植物油 洋葱浆 温水 洋葱浆馕 1000 18 30 5 24 270 300 表 2 馕感官评分标准

Table 2 Sensory evaluation standards of Nang

感官指标 评分标准 分数(分) 色泽 金黄色,焦色均匀,无焦糊现象 16~20 淡黄色,焦色较均匀,略有焦糊现象 11~15 黄棕色或乳白色,焦色较差,有明显焦糊现象 0~10 风味 浓郁的醒发和烘烤后的洋葱馕香味,酵母或配料味适中 17~20 淡淡的醒发和发酵后的洋葱馕香味,无异味 13~16 较淡的醒发和烘烤后的洋葱馕香味,酵母和配料味稍重 9~12 无洋葱馕特有的香味,酵母或配料产生的不良气味严重 0~8 形态 圆形规则,表面平整,厚薄均匀,花纹清晰,无明显鼓泡 15~20 圆形规则,表面较平整,厚薄均匀,花纹清晰,有少量的鼓泡 9~14 圆形不规则,表面较平整,厚度不均匀,花纹不清晰,有较大的鼓泡 0~8 口感 软硬适中,不粘牙,略有嚼劲 20~25 硬度偏硬或偏软,较粘牙,较有嚼劲 14~19 干硬,粘牙,不易下咽,嚼劲较大 0~13 组织结构 质地细腻,气孔均匀,柔软有弹性 11~15 质地细腻,气孔较均匀,弹性较差 6~10 质地不细腻,气孔不均匀,无弹性 0~5 表 3 响应面试验因素与水平

Table 3 Factors and levels of response surface test

水平 A 单甘酯

添加量(%)B 大豆磷脂

添加量(%)C α-淀粉酶

添加量(%)D 甘油

添加量(%)1 0.4 0.5 0.05 1.5 2 0.5 0.6 0.06 2.0 3 0.6 0.7 0.07 2.5 表 4 单甘酯添加量对洋葱浆馕馕边质构特性的影响

Table 4 Effect of monoglyceride addition on texture properties of Nang edge of onion pulp

单甘酯添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1768.89±28.45e 1.26±0.59b 0.48±0.02a 1104.01±69.99d 0.3 1570.07±55.73d 0.88±0.04ab 0.53±0.01b 903.81±65.68c 0.4 1396.28±77.97c 0.83±0.01ab 0.58±0.01c 767.32±34.73b 0.5 1182.99±77.14b 0.80±0.00a 0.67±0.05d 638.57±22.74a 0.6 1069.27±62.37a 0.76±0.01a 0.57±0.01bc 589.33±62.55a 0.7 1005.31±39.50a 0.74±0.00a 0.54±0.01bc 618.77±71.78a 注:不同字母表示同列中数值间显著性差异(P<0.05);表5~表11同。 表 5 单甘酯添加量对洋葱浆馕馕心质构特性的影响

Table 5 Effect of monoglyceride addition on textural properties of Nang core of onion paste

单甘酯添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1929.22±71.82e 1.01±0.20b 0.52±0.02a 1058.75±61.22d 0.3 1644.00±130.42d 0.89±0.02ab 0.58±0.01b 962.96±1471c 0.4 1443.11±44.16c 0.86±0.01ab 0.62±0.01c 846.1±128.51b 0.5 1199.79±63.13b 0.83±0.01a 0.67±0.02d 714.15±35.48a 0.6 1070.49±48.12b 0.80±0.01a 0.61±0.03bc 691.88±18.93a 0.7 903.17±86.80a 0.76±0.03a 0.58±0.01b 707.92±79.90a 表 6 大豆磷脂添加量对洋葱浆馕馕边质构特性的影响

Table 6 Effect of soybean lecithin addition on texture properties of Nang edge of onion paste

大豆磷脂添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1780.44±43.02d 1.01±0.04e 0.52±0.02a 478.07±17.97a 0.3 1666.09±26.79d 0.90±0.02d 0.56±0.01c 530.17±27.17b 0.4 1469.89±6235c 0.85±0.01bc 0.58±0.01d 582.29±14.45c 0.5 1326.54±43.21b 0.77±0.01a 0.54±0.01b 471.39±10.16a 0.6 1127.42±91.94a 0.83±0.01b 0.61±0.01e 571.43±12.15c 0.7 1206.99±109.72a 0.88±0.01cd 0.57±0.01cd 500.69±8.63a 表 7 大豆磷脂添加量对洋葱浆馕馕心质构特性的影响

Table 7 Effect of soybean lecithin addition on texture properties of Nang core of onion paste

大豆磷脂添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1974.16±43.93e 1.02±0.20b 0.49±0.01a 590.67±65.96a 0.3 1757.96±11.11d 0.88±0.02ab 0.54±0.01b 714.89±15.19bc 0.4 1646.51±81.50c 0.84±0.01a 0.62±0.01d 773.75±27.22c 0.5 1405.20±70.30b 0.79±0.01a 0.58±0.01c 653.94±14.50ab 0.6 1213.18±25.64a 0.85±0.01a 0.63±0.01d 744.38±10.95c 0.7 1303.39±53.50a 0.89±0.00ab 0.57±0.01c 608.4±765.09a 表 8 α-淀粉酶添加量对洋葱浆馕馕边质构特性的影响

Table 8 Effect of a-amylase addition on texture characteristics of Nang edge of onion paste

a-淀粉酶添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1470.49±35.76d 0.76±0.01b 0.47±0.01a 625.88±49.54b 0.04 1346.80±42.23c 0.72±0.02a 0.50±0.01b 535.25±25.21a 0.05 1196.18±42.56b 0.82±0.01c 0.53±0.01c 478.86±15.96a 0.06 1025.73±76.53a 0.87±0.00d 0.58±0.01d 517.17±14.15a 0.07 1234.03±31.40b 0.81±0.01c 0.61±0.02e 502.18±59.91a 0.08 1331.85±30.42c 0.75±0.05ab 0.54±0.01c 482.14±26.65a 表 9 α-淀粉酶添加量对洋葱浆馕馕心质构特性的影响

Table 9 Effect of a-amylase addition on texture characteristics of Nang core of onion paste

a-淀粉酶添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1672.49±52.14d 0.80±0.03b 0.54±0.01a 775.57±80.51c 0.04 1519.08±24.89c 0.76±0.01a 0.56±0.04a 516.19±13.78a 0.05 1391.82±52.80b 0.85±0.01c 0.63±0.02b 558.21±26.37a 0.06 1267.42±37.32a 0.90±0.02d 0.67±0.01c 673.61±58.61b 0.07 1379.72±47.18b 0.85±0.01c 0.63±0.01a 583.25±41.06ab 0.08 1443.83±30.09b 0.82±0.02bc 0.58±0.01a 520.27±69.01a 表 10 甘油添加量对洋葱浆馕馕心质构特性的影响

Table 10 Effect of glycerol addition on texture characteristics of Nang edge of onion paste

甘油添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1572.45±58.05e 0.97±0.08c 0.63±0.02c 1156.76±64.28d 0.5 1384.52±52.63d 0.80±0.02a 0.55±0.01a 972.34±33.29c 1.0 1212.75±75.21c 0.84±0.01a 0.58±0.01b 866.59±39.47b 1.5 1015.42±72.83b 0.85±0.01ab 0.62±0.01c 779.97±17.34ab 2.0 940.09±16.05a 0.91±0.01b 0.67±0.01d 858.96±57.44b 2.5 1142.62±42.30b 0.86±0.01ab 0.62±0.02c 706.57±72.58a 表 11 甘油添加量对洋葱浆馕馕心质构特性的影响

Table 11 Effect of glycerol addition on texture characteristics of Nang core of onion paste

甘油添加量(%) 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 0 1752.10±27.03e 1.00±0.11c 0.68±0.01d 1099.18±85.98d 0.5 1470.58±72.40d 0.84±0.01a 0.56±0.01a 972.19±55.72c 1.0 1315.57±71.31c 0.87±0.01ab 0.58±0.01b 861.59±52.31b 1.5 1207.90±58.53b 0.88±0.01ab 0.62±0.01c 723.25±27.03a 2.0 1082.24±62.74a 0.94±0.02bc 0.67±0.01d 828.19±81.17b 2.5 1239.59±53.13b 0.87±0.01ab 0.62±0.01c 706.04±16.72a 表 12 响应面试验设计与结果

Table 12 Design and results of response surface test

试验号 A B C D 感官评分 硬度(g) 弹性(mm) 内聚性 咀嚼性(mJ) 1 1 −1 0 0 83.29 1286.87 0.85 0.59 779.63 2 0 0 0 0 91.23 1191.11 1.18 0.68 529.63 3 −1 0 1 0 86.13 1246.47 0.94 0.52 749.63 4 0 1 1 0 84.49 1267.47 0.88 0.56 713.12 5 0 −1 0 −1 80.73 1318.51 0.65 0.71 689.92 6 0 −1 1 0 80.43 1324.67 0.74 0.71 902.79 7 −1 0 −1 0 78.33 1368.27 0.67 0.76 976.99 8 0 −1 0 1 81.79 1317.87 0.69 0.7 672.14 9 0 0 0 0 90.49 1198.87 1.14 0.48 546.08 10 −1 0 0 1 84.93 1254.87 0.92 0.54 683.66 11 0 0 0 0 90.19 1204.47 1.09 0.48 575.83 12 1 1 0 0 82.23 1301.07 0.8 0.64 1019.13 13 −1 1 0 0 87.33 1242.27 0.97 0.51 632.55 14 −1 −1 0 0 84.33 1271.67 0.86 0.57 738.31 15 0 0 −1 −1 75.23 1444.11 0.55 0.81 1071.94 16 0 0 −1 1 75.39 1432.51 0.61 0.8 1054.7 17 1 0 −1 0 75.63 1422.87 0.63 0.79 1035.79 18 −1 0 0 −1 83.73 1275.87 0.91 0.59 849.98 19 0 −1 −1 0 77.73 1408.31 0.66 0.77 998.45 20 0 0 0 0 89.73 1233.87 1.08 0.51 608.1 21 0 0 1 −1 78.63 1351.47 0.88 0.73 855.46 22 1 0 0 −1 80.13 1326.27 0.62 0.71 830.23 23 0 1 0 −1 79.23 1327.51 0.71 0.72 942.86 24 1 0 1 0 82.53 1290.71 0.71 0.62 801.02 25 0 1 0 1 82.99 1290.71 0.84 0.59 794.72 26 0 0 1 1 81.93 1311.71 0.83 0.67 835.34 27 0 1 −1 0 75.69 1411.87 0.74 0.77 1011.78 28 0 0 0 0 89.89 1205.31 0.9 0.5 598.16 29 1 0 0 1 81.79 1312.67 0.71 0.68 859.26 表 13 感官评分和质构特性间的相关系数

Table 13 Correlation coefficient between sensory score and texture characteristics

品质指标 感官评分 硬度 弹性 内聚性 咀嚼性 感官评分 1.000 硬度 −0.976** 1.000 弹性 0.895** −0.859** 1.000 内聚性 −0.886** 0.896** −0.784** 1.000 咀嚼性 −0.911** 0.902** −0.786** 0.786** 1.000 注: **表示差异极显著(P<0.01)。 表 14 响应面回归模型方差分析表(硬度)

Table 14 Analysis of variance of response surface regression model (Hardness)

方差来源 平方和 自由度 均方 F值 P 显著性 模型 1.41E+05 14 10065.2 71.26 < 0.0001 ** A 6581.96 1 6581.96 46.6 < 0.0001 ** B 630.75 1 630.75 4.47 0.053 C 40303.07 1 40303.07 285.33 < 0.0001 ** D 1268.96 1 1268.96 8.98 0.0096 ** AB 475.24 1 475.24 3.36 0.0880 AC 26.83 1 26.83 0.19 0.6696 AD 13.69 1 13.69 0.097 0.7601 BC 922.94 1 922.94 6.53 0.0228 * BD 326.89 1 326.89 2.31 0.1505 CD 198.25 1 198.25 1.4 0.2559 A2 2955.86 1 2955.86 20.93 0.0004 ** B2 11695.27 1 11695.27 82.8 < 0.0001 ** C2 73456.72 1 73456.72 520.04 < 0.0001 ** D2 29006.69 1 29006.69 205.35 < 0.0001 ** 残差 1977.53 14 141.25 失拟项 928.06 10 92.81 0.35 0.9168 纯误差 1049.47 4 262.37 总和 1.43E+05 28 R2=0.9862 R2Adj=0.9723 C.V.%=0.91 注: **表示差异极显著(P<0.01),*表示差异显著(P<0.05)。 表 15 优化前后洋葱浆馕的品质指标

Table 15 Quality index of onion paste Nang before and after optimization

贮藏时间(d) 样品 感官评分 硬度(g) 0 优化前洋葱浆馕馕边 80.62±0.19 1763.90±68.2 优化后洋葱浆馕馕边 91.28±0.35 1142.29±87.53 6 优化前洋葱浆馕馕边 72.03±0.39 8201.52±169.3 优化后洋葱浆馕馕边 85.52±0.21 3613.94±52.67 -

[1] 安尼瓦尔·哈斯木. 馕, 馕坑与馕文化漫谈[J]. 新疆地方志,2017(2):53−58. [ANNIWAL Hasmu. Nang, Nang pit and Nang culture[J]. Xinjiang Local Chronicles,2017(2):53−58. doi: 10.3969/j.issn.1004-1826.2017.02.028 [2] 王强. 复配酶制剂在面包抗老化方面的应用研究[D]. 厦门: 集美大学, 2014. WANG Qiang. Application of compound enzyme preparation in bread aging resistance[D]. Xiamen: Jimei University, 2014.

[3] 詹冬玲, 任玉雪, 闵伟红, 等. 面包老化机理及其分析技术的研究进展[J]. 食品工业科技,2013,34(23):353−355. [ZHAN Dongling, REN Yuxue, MIN Weihong, et al. Research progress on bread aging mechanism and its analysis technology[J]. Food Industry Science and Technology,2013,34(23):353−355. [4] 钟宝瑜, 陆利霞, 熊晓辉. 复合乳化剂对面包品质及货架期影响研究[J]. 食品与发酵工业,2018,44(7):192−198. [ZHONG Baoyu, LU Lixia, XIONG Xiaohui. Study on the effect of compound emulsifier on bread quality and shelf life[J]. Food and Fermentation Industry,2018,44(7):192−198. [5] 王雨, 薛自萍. 影响面包老化的因素及延缓措施[J]. 农产品加工,2019(10):82−83. [WANG Yu, XUE Ziping. Factors affecting bread aging and delay measures[J]. Agricultural Products Processing,2019(10):82−83. [6] 吴昌术, 刘双. 面包老化的机理及控制途径[J]. 安徽农学通报,2017,23(5):100−102, 114. [WU Changzhu, LIU Shuang. Mechanism and control approaches of bread aging[J]. Anhui Agronomy Bulletin,2017,23(5):100−102, 114. doi: 10.3969/j.issn.1007-7731.2017.05.040 [7] MAO Huijia, LI Jie, CHEN Zhijun, et al. Molecular structure of different prepared pyrodextrins and the inhibitory effects on starch retrogradation[J]. Food Research International,2021:143.

[8] LI Cheng, HU Yiming, LI Enpeng. Effects of amylose and amylopectin chain-length distribution on the kinetics of long-term rice starch retrogradation[J]. Food Hydrocolloids,2021:111.

[9] PÉREZ ISELA Carballo, MU Taihua, ZHANG Miao, et al. Effect of heat treatment to sweet potato flour on dough properties and characteristics of sweet potato-wheat bread.[J]. Food Science and Technology International,2017,23(8):708−715. doi: 10.1177/1082013217719006

[10] MAGHAYDAH S, ABDUL-HUSSAIN S, AJO R, et al. Utilization of different hydrocolloid combinations in gluten-free bread making[J]. Food & Nutrition Sciences,2013,4(5):496−502.

[11] 洪文龙. 不同面包改良剂对面团流变学的影响及复配研究[J]. 现代食品,2017(15):114−118. [HONG Wenlong. Effects of different bread modifiers on dough rheology and their compounding[J]. Modern Food,2017(15):114−118. [12] 徐超宇, 马晓军. 面包改良剂对红薯面包面团流变特性的影响及改良剂的优化分析[J]. 食品工业科技,2015,36(19):267−274. [XU Chaoyu, MA Xiaojun. Effect of bread modifier on rheological properties of sweet potato bread dough and optimization analysis of modifier[J]. Food Industry Science and Technology,2015,36(19):267−274. [13] 于海霞, 孙彩玲, 田纪春. 不同型号面包改良剂对面包品质影响的研究[J]. 粮食加工,2007(4):78−80. [YU Haixia, SUN Cailing, TIAN Jichun. Effects of different types of bread improvers on bread quality[J]. Grain Processing,2007(4):78−80. [14] 任立焕, 赵江, 刘子圆, 等. 不同改良剂对马铃薯面条品质的影响[J]. 粮食与油脂,2017,30(9):35−38. [REN Lihuan, ZHAO Jiang, LIU Ziyuan, et al. Effects of different modifiers on potato noodle quality[J]. Grain and Oil,2017,30(9):35−38. doi: 10.3969/j.issn.1008-9578.2017.09.010 [15] 王慧洁, 白岩, 张国治, 等. 复合改良剂对甜玉米馒头品质的影响研究[J]. 河南工业大学学报(自然科学版),2020,41(5):50−56. [WANG Huijie, BAI Yan, ZHANG Guozhi, et al. Study on the effect of compound modifier on the quality of sweet corn steamed bread[J]. Journal of Henan University of Technology (Natural Science Edition),2020,41(5):50−56. [16] 喻勤, 王玺, 林静, 等. 马铃薯面包复配改良剂的优选及其对面包质构特性的影响[J]. 食品研究与开发,2019,40(13):26−33. [YU Qin, WANG Xi, LIN Jing, et al. Optimization of potato bread compound modifier and its effect on bread texture characteristics[J]. Food Research and Development,2019,40(13):26−33. [17] LI Y T, CHEN M S, DENG L Z, et al. Whole soybean milk produced by a novel industry-scale micofluidizer system without soaking and filtering[J]. Journal of Food Engineering,2020,291(4):110228.

[18] 冯凤琴, 杜鹃, 王小刘. 食品防腐乳化剂月桂酸单甘油酯及其在食品中的应用[J]. 中国食品添加剂,2009(S1):173−177. [FENG Fengqin, DU Juan, WANG Xiaoliu. Food preservative emulsifier monoglyceride laurate and its application in food[J]. China Food Additives,2009(S1):173−177. [19] 张洁, 张惠琴, 彭洒洒, 等. 浅谈改良剂在面粉中的应用[J]. 现代面粉工业,2020,34(6):18−21. [ZHANG Jie, ZHANG Huiqin, PENG Sasa, et al. On the application of improvers in flour[J]. Modern Flour Industry,2020,34(6):18−21. doi: 10.3969/j.issn.1674-5280.2020.06.005 [20] 田志刚, 孙洪蕊, 刘香英, 等. 面包改良剂对马铃薯面包质构特性的影响[J]. 食品工业,2018,39(6):18−21. [TIAN Zhigang, SUN Hongrui, LIU Xiangying, et al. Effects of bread improvers on texture properties of potato bread[J]. Food Industry,2018,39(6):18−21. [21] 潘淇, 胡明华, 张素英, 等. 食用乳化剂在蛋糕生产中的应用研究[J]. 黑龙江科学,2020,11(12):40−41. [PAN Qi, HU Minghua, ZHANG Suying, et al. Application of edible emulsifier in cake production[J]. Heilongjiang Science,2020,11(12):40−41. doi: 10.3969/j.issn.1674-8646.2020.12.015 [22] 邹奇波, 王家宝, 陈诚, 等. 乳化剂和保泡型流态起酥油对海绵蛋糕面糊及其烘焙特性的影响[J]. 食品与机械,2019,35(11):28−33,151. [ZOU Qibo, WANG Jiabao, CHEN Cheng, et al. Effects of emulsifier and foam preserving fluid shortening on sponge cake batter and its baking characteristics[J]. Food and Machinery,2019,35(11):28−33,151. [23] 王彩虹, 纵曼利, 刘玉洁, 等. 洋葱酥性饼干的工艺研究[J]. 农产品加工,2020(16):33−37. [WANG Caihong, ZONG Manli, LIU Yujie, et al. Study on the technology of onion crisp biscuits[J]. Agricultural Products Processing,2020(16):33−37. [24] 邹淑萍, 许铭强, 张春平, 等. 马铃薯粉添加量对新疆馕加工品质的影响[J]. 中国粮油学报,2020,35(11):33−39. [ZOU Shuping, XU Mingqiang, ZHANG Chunping, et al. Effect of potato powder addition on the processing quality of Xinjiang Nang[J]. Chinese Journal of Grain and Oil,2020,35(11):33−39. doi: 10.3969/j.issn.1003-0174.2020.11.007 [25] 豆康宁, 赵永敢, 王飞, 等. 蒸馏单硬脂酸甘油酯对面粉品质的改良研究[J]. 现代面粉工业,2016,30(6):27−29. [DOU Kangning, ZHAO Yonggan, WANG Fei, et al. Study on the improvement of flour quality by distilling glycerol monostearate[J]. Modern Flour Industry,2016,30(6):27−29. doi: 10.3969/j.issn.1674-5280.2016.06.011 [26] 邱惠, 庞庭才, 黄海, 等. 不同乳化剂对糯米糕品质的影响及抗老化研究[J]. 食品研究与开发,2021,42(5):15−20. [QIU Hui, PANG Tingcai, HUANG Hai, et al. Effects of different emulsifiers on the quality of glutinous rice cakes and anti aging research[J]. Research and Development,2021,42(5):15−20. [27] 何松, 谢敏华, 黄美凤. 复配乳化酶制剂对面包柔软度的改善研究[J]. 中国食品添加剂,2019,30(8):120−125. [HE Song, XIE Minhua, HUANG Meifeng. Study on improvement of dough softness of compound emulsified enzyme preparation[J]. China Food Additives,2019,30(8):120−125. doi: 10.3969/j.issn.1006-2513.2019.08.014 [28] AZIZI M H, RAO G V. Effect of surfactant gel and gum combinations on dough rheological characteristics and quality of bread[J]. Journal of Food Quality,2004,27(5):320−336. doi: 10.1111/j.1745-4557.2004.00600.x

[29] 徐云峰, 杨哪, 金征宇, 等. 复配大豆磷脂和蔗糖酯对面包酵母冷冻保护作用[J]. 食品与生物技术学报,2011,30(2):213−217. [XU Yunfeng, YANG Na, JIN Zhengyu, et al. Cryoprotective effect of compound soybean phospholipids and sucrose esters on Baker's yeast[J]. Journal of Food and Biotechnology,2011,30(2):213−217. [30] 冯德伟, 张家伟, 谢晓航, 等. 复配改良剂对馒头品质的影响以及质构分析[J]. 大众科技,2020,22(2):44−47. [FENG Dewei, ZHANG Jiawei, XIE Xiaohang, et al. Effect of compound modifier on steamed bread quality and texture analysis[J]. Dazhong Science and Technology,2020,22(2):44−47. doi: 10.3969/j.issn.1008-1151.2020.02.012 [31] 王梦雨, 曾洁, 张珂珂, 等. 面包复合乳化剂的研究及优化[J]. 河南科技学院学报(自然科学版),2021,49(2):34−40. [WANG Mengyu, ZENG Jie, ZHANG Keke, et al. Research and optimization of bread compound emulsifier[J]. Journal of Henan University of Science and Technology (Natural Science Edition),2021,49(2):34−40. [32] 陈海峰, 杨其林, 何唯平. 面粉改良中酶制剂的作用[J]. 粮食加工,2007(2):26−27. [CHEN Haifeng, YANG Qilin, HE Weiping. The role of enzymes in flour improvement[J]. Grain Processing,2007(2):26−27. [33] GIANNONE V, LAURO M R, SPINA A, et al. A novel α-amylase-lipase formulation as antistaling agent in durum wheat bread[J]. LWT-Food Science & Technology,2016,65:381−389.

[34] LIEN R Gerits, BRAM Pareyt, HANNE G Masure, et al. A lipase based approach to understand the role of wheat endogenous lipids in bread crumb firmness evolution during storage[J]. LWT-Food Science and Technology,2015,64(2):874−880. doi: 10.1016/j.lwt.2015.06.055

[35] 苏东民, 贺鸣, 钱平, 等. 甘油对面包品质及其耐贮存特性的影响[J]. 河南工业大学学报(自然科学版),2007,28(3):1−4. [SU Dongmin, HE Ming, QIAN Ping, et al. Effect of glycerol on bread quality and storage resistance[J]. Journal of Henan University of Technology (Natural Science Edition),2007,28(3):1−4. [36] POUPLIN M, REDL A, GONTARD N. Glass transition of wheat gluten plasticized with water, glycerol, or sorbitol[J]. Journal of Agricultural & Food Chemistry,1999,47(2):538−543.

[37] TANG X, ZHANG B, HUANG W, et al. Hydration, water distribution and microstructure of gluten during freeze thaw process: Role of a high molecular weight dextran produced by Weissella confusa QS813[J]. Food Hydrocolloids,2019,90:377−384. doi: 10.1016/j.foodhyd.2018.10.025

[38] LIZOTTE D J, GREINER R, SCHUURMANS D. An experimental methodology for response surface optimization methods[J]. Journal of Global Optimization,2012,53(4):699−736. doi: 10.1007/s10898-011-9732-z

[39] 王宁宁, 冯美琴, 孙健. 响应面法优化发酵香肠的低钠复合盐配方[J]. 食品工业科技,2021,42(22):169−177. [WANG Ningning, FENG Meiqin, SUN Jian. Optimization of low sodium compound salt formula for fermented sausage by response surface methodology[J]. Food Industry Science and Technology,2021,42(22):169−177.

下载:

下载:

下载:

下载: